Maintenance – Glow-worm Clearly Heat Pumps 5kW User Manual

Page 23

0020096879_01 - 06/10 - Glow-worm

- 21 -

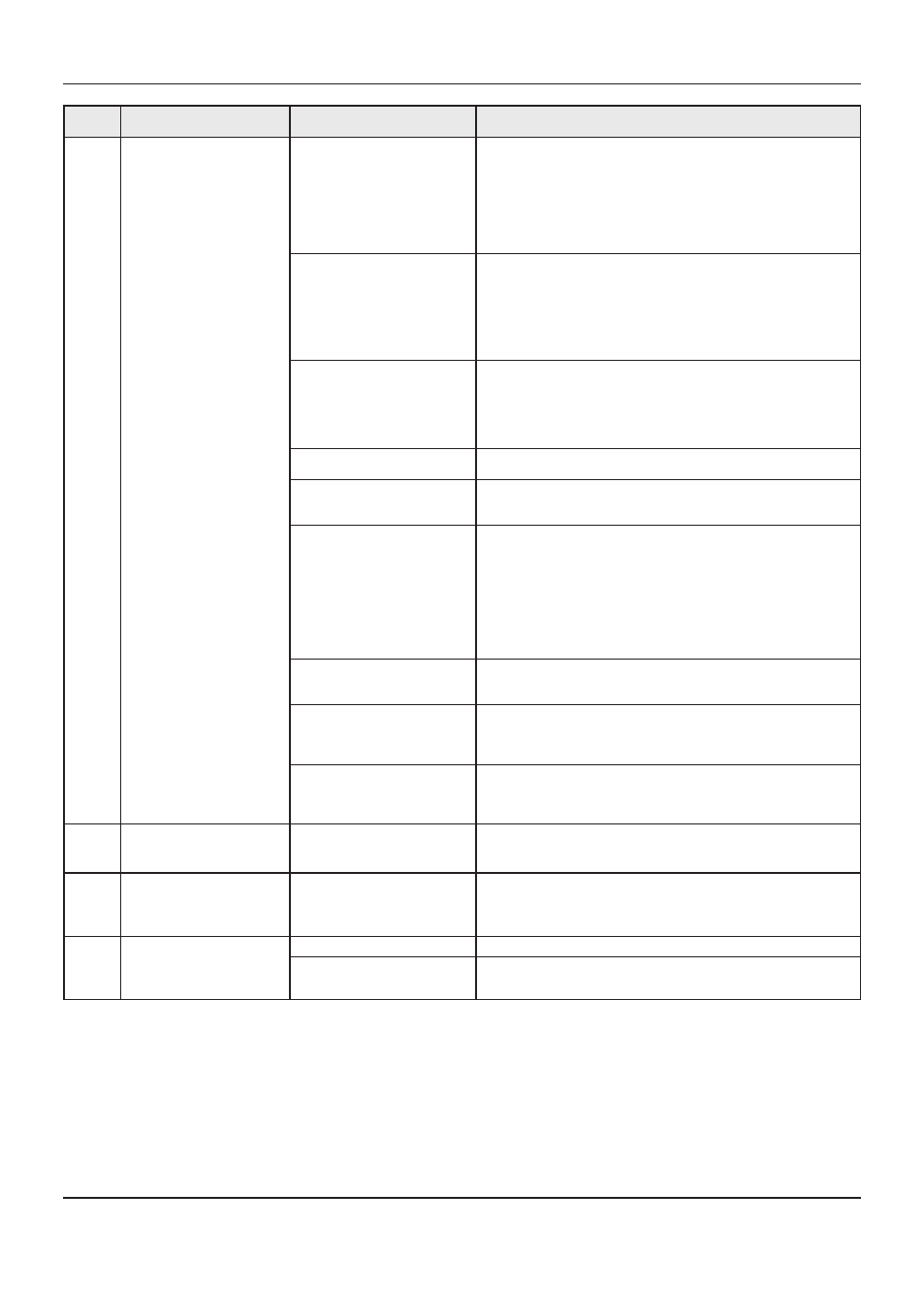

MAINTENANCE

fault

codes Description

Cause

Solution

554

Operation outside the

compressor shell

- in heating mode :

(BP> 15 Bar or HP <11 bar or

HP> 40 Bar).

- in cooling mode :

(BP< 4.5 Bar or BP > 15 Bar or

HP < 11 Bar or HP > 40 Bar).

Non-blocking failure.

An excess or a lack of refrigerant.

Measure the air and water’s ΔT. If it is very low (<2K), lack of fluid

may be the cause (loss of heat output). Measure the real overheating

(must be <7K in heating mode). Measure the electrical current with an

ammeter. If the current is below 4.5 amps, the cause may be a lack of

fluid.

Check the pressure with a monometer.

Check that there are no leaks, repair them if necessary.

Adjust the amount of refrigerant.

Presence of incondensables.

Measure the discharge temperature. High temperatures (> 90 ° C in

cool environmental conditions from 0 to 12 ° C) may be due to the

presence of incondensables. Use a manometer to check the presence

of incondensables. Following prolonged periods of inactivity of the

compressor, ensure that the temperatures indicated correspond

to those of the fluid temperature (environmental or condenser or

evaporator).

The electronic expansion valve is

defective.

Check that the electronic expansion valve is working correctly, if this is

not the case:

Check the winding resistance.

Clip the electronic expansion valve back on.

Replace the motor.

Replace the electronic expansion valve, check that there are no leaks.

Pre-expansion in the liquid line

(load loss)

Check the appearance of the condenser output tubes leading to the

evaporator (do not pinch).

Insufficient heat exchange at the

plate to plate exchanger or tube

exchanger.

Check for accumulation of dirt in the heat exchanger plates.

Check for obstruction of the fan grille.

The 4-way valve is defective.

Check the power supply to the valve. Force in the defrost mode and

check the reverse cycle.

If the reverse cycle does not work, change the valve. If the problem

persists:

Check the temperatures of the 4-way valve’s input and output tubes.

Those of the suction tubes must be identical, but lower than those of

the discharge. If this is not the case, the 4-way valve’s slide is stuck in

an intermediate position, change the 4-way valve. Check for leaks and

repair if necessary.

The heating outlet and return

temperature sensors are

defective

Check the sensor connections.

Check that the sensor position and operation are correct.

Check the sensor resistance.

The air temperature is too high in

heating mode

Check the agreement between the outside sensor and heat pump air

inlet temperature sensor.

Check that the heat pump air inlet temperature sensor is working

properly.

The air temperature is too high in

cooling mode

Check the agreement between the outside sensor and heat pump air

inlet temperature sensor.

Check that the heat pump air inlet temperature sensor is working

properly.

581

Failure of the defrosting

temperature sensor.

The sensor is defective or is not

correctly connected to the main

PCB.

Check the sensor’s connections. Check that the position and the

operation of the sensor are correct.

Check the sensor’s resistance.

582

Failure of motor regulator.

The regulator’s motor or its

connection is faulty

Check the winding resistance.

Check the condition of the regulator’s cables.

Check the regulator’s 24 V power supply at the main PCB.

Replace the motor.

583

The temperature of the plate

heat exchanger is too low

(<0ºC).

Non-blocking failure

Incorrect setting.

Check the control unit settings.

A temperature sensor is poorly

positioned.

Check the position of the external temperature sensors.

Ensure an optimum thermal contact.