0 maintenance, Unit, Figure 9: potentiometer location – ENMET MX-42A User Manual

Page 17

MX42A C

ONTROL

ENMET Corporation

13

5.0 Maintenance

5.0 Maintenance

5.0 Maintenance

5.0 Maintenance

The

MX 42A

C

ONTROL

requires practically no servicing at all. Nevertheless, since it is a safety device, it is still

necessary to calibrate the detectors periodically.

C

AUTION

:

The procedures and adjustments described in the following sections must be performed by authorized

personal. Failure to follow instructions may jeopardize accurate measurements.

5.1 Adjustment of sensor/transmitter and the MX 42A C

ONTROL

unit

adjustment consists of calibrating the zero of the sensor/transmitter in clean air and the gain of the sensor/transmitter to

the reference gas.

For each channel, set the microswitches as follows

Microswitch 8 = in operation

Microswitch 7 = maintenance

Microswitch 6 = calibration

In the maintenance mode, the Control current output is set to 2 mA.

N

OTE

:

If left in calibration mode, the channel automatically changes over to fault after 30 minutes.

Voltmeter readings are taken at test points of sensor/transmitter refer to S/T manual for location and across

OUTPUT+

, 4-20mA–

terminal for each channel of the

MX42A

C

ONTROL

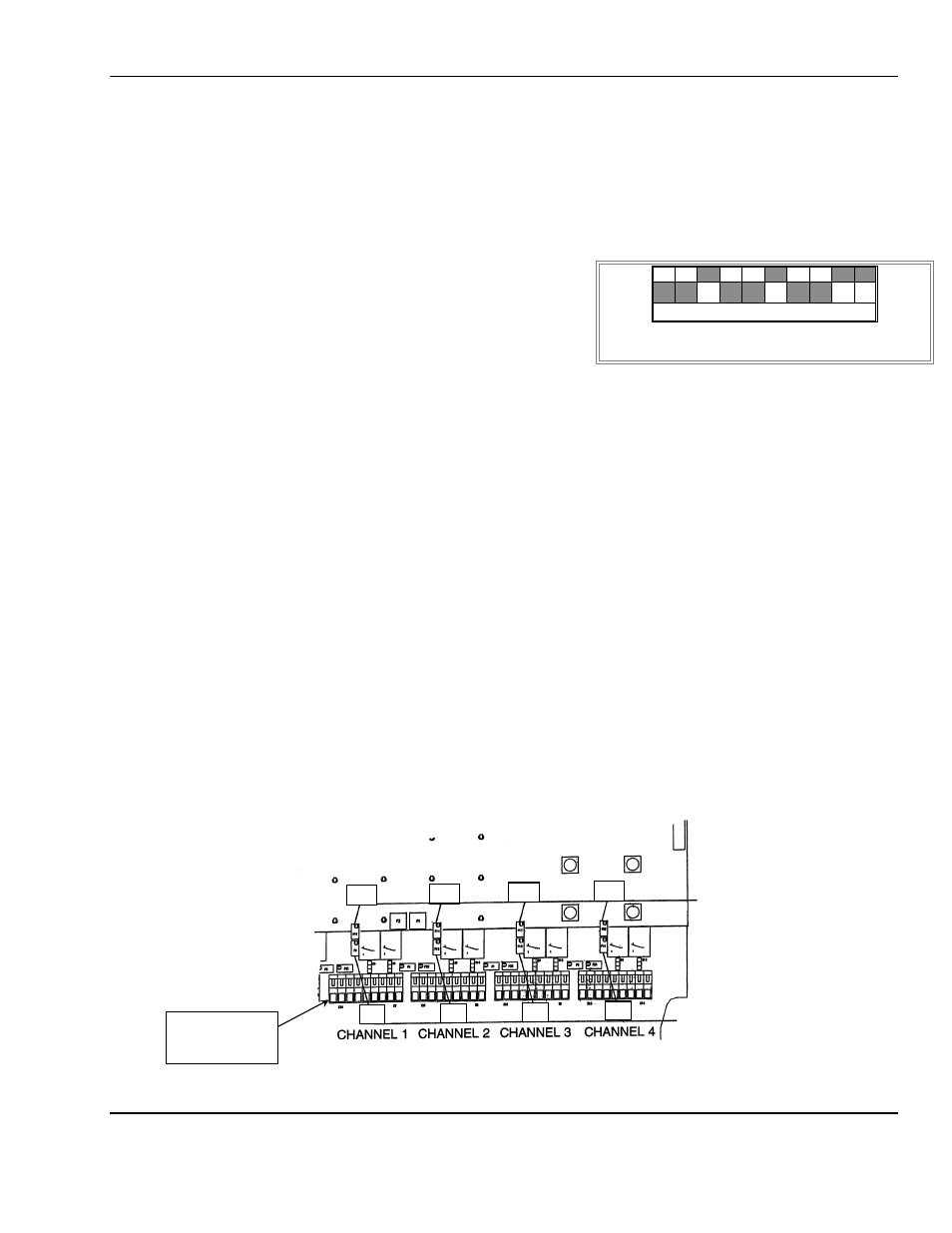

. See F

IGURE

4, 9.

Adjustment of MX42A C

ONTROL

zero

With the sensor/transmitter in clean air, set the output of the sensor/transmitter to zero (4mA). Then use MX42A

potentiometer: F

IGURE

9, Zero Adjust

P9 for channel 1

P12 for channel 2

P15 for channel 3

P18 for channel 4

to display 0000 on the channel in question. If the ambient air at S/T is not free of contamination, use air from a cylinder.

Adjustment MX42A C

ONTROL

gain

•

Apply the correct calibration gas to the sensor/transmitter, and set the sensor/transmitter output to appropriate output

see S/T manual for proper setting.

•

Adjust the

CONTROL

display to the value of the calibration gas using potentiometer:

F

IGURE

9, Span Adjust

P11 for channel 1

P14 for channel 2

P17 for channel 3

P20 for channel 4

Remove Calibration Gas and return to the microswitch configuration to normal operation:

Microswitch 8 = in operation

Microswitch 7 = normal

Microswitch 6 = calibration

Figure 9: Potentiometer Location

Zero Adjust

POTs

Span Adjust

POTs

1

2

3

4

5

6

7

8

9

10

Example of Microswitch in calibration mode

gray areas indicate position of each switch

P11

P9

P14

P17

P20

P12

P15

P18

Terminal

Cannel 1