0 maintenance – ENMET ISA-44-2OD User Manual

Page 18

ENMET Corporation

ISA-44-2-OD

14

5.0 Maintenance

5.0 Maintenance

The ISA-44-2-OD hazardous gas and oxygen deficiency monitor is a safety instrument and requires periodic testing

and recalibration at regular intervals. Also, check for obvious mechanical damage or malfunctions such as burned out

lamps.

Purge the sensor periodically. This interval varies with the amount of contaminants in the atmosphere.

5.1 Routine Gas Test

Perform this test at regular intervals. You decide how often; we recommend that you perform this test at least once

every six weeks.

N

OTE

: The gases should be identical, or equivalent (correlation gas) to those used to initially calibrate the unit, unless

you want to recalibrate to a new gas or different concentration. In addition, calibration gases must be in a

background of air; do not use gases with an inert gas background (such as nitrogen or argon).

Test

Y

OU NEED

:

§

Cylinder of high-level calibration gas with air used as background gas (for example 200 ppm CO in air)

§

Calibration fixture (with humidifier/regulator, plastic tubing and calibration cup); ENMET part # 03700-001

§

Clean water

§

Small screwdriver

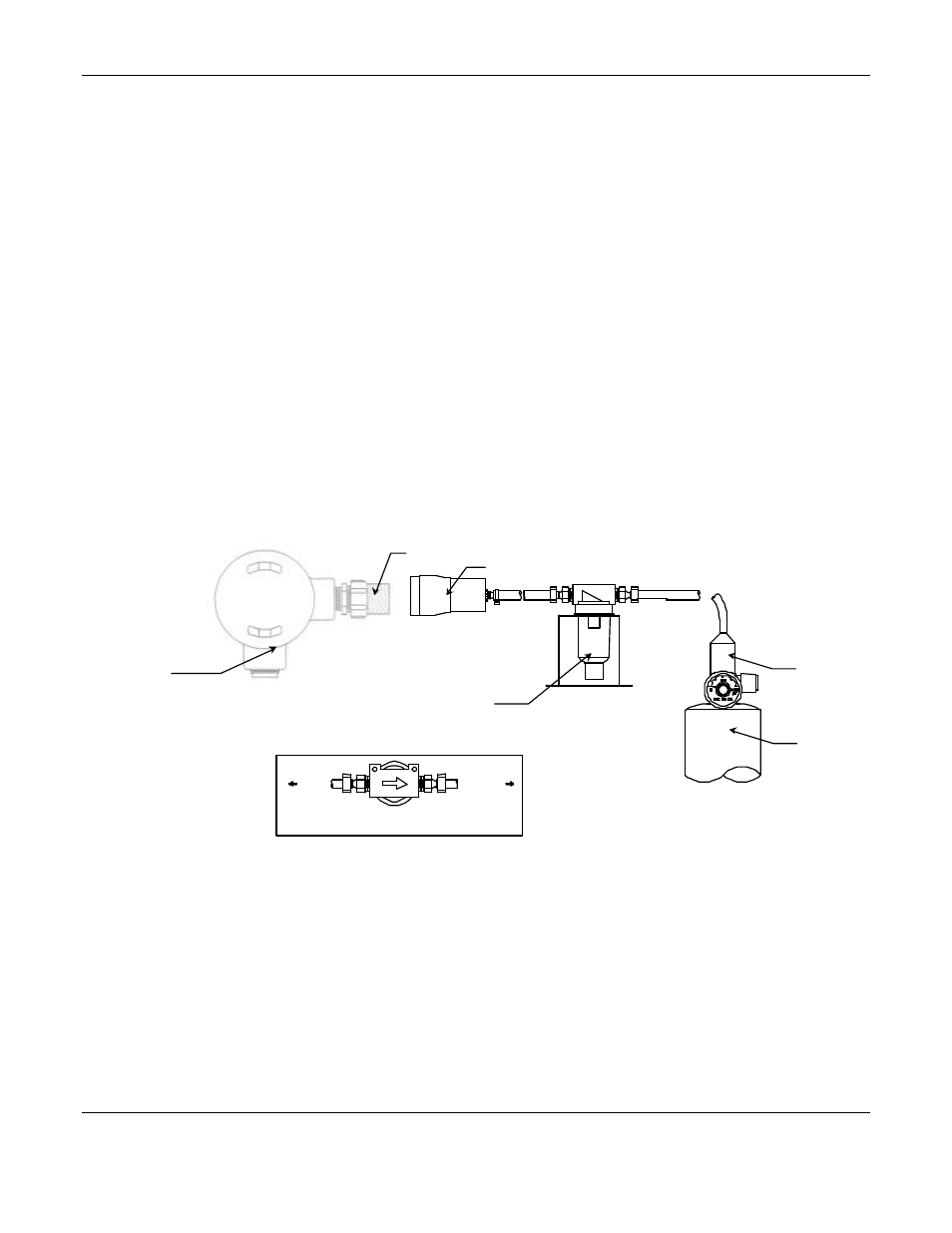

Figure 9: Exposing a Sensor to Test or Calibration Gas

P

ROCEDURE

:

1. The unit must operate continuously for at least 24 hours before this test.

2. After 24 hours, turn the HORN O

FF

.

3. On units requiring purging, rotate switch to P

URGE

ON, purge for 20 minutes. After the purge, rotate switch to

H

ORN

OFF, wait 20 minutes for the sensor to stabilize.

4. Fill the humidifier bottle with tap water about half-way.

5. Attach the calibration fixture to the high-level gas cylinder. Set humidifier upright on a level surface.

6. Open the valve to allow a steady stream of gas to bubble through the water.

Sensor

Enclosure

Sensor

Gas Cylinder

Regulator

Humidifier

Calibration Cup

To Cal Cup

Top View of Humidifier

To Regulator