2 sample air supply, 3 power supply, 4 outputs – ENMET PROAIR 2200 User Manual

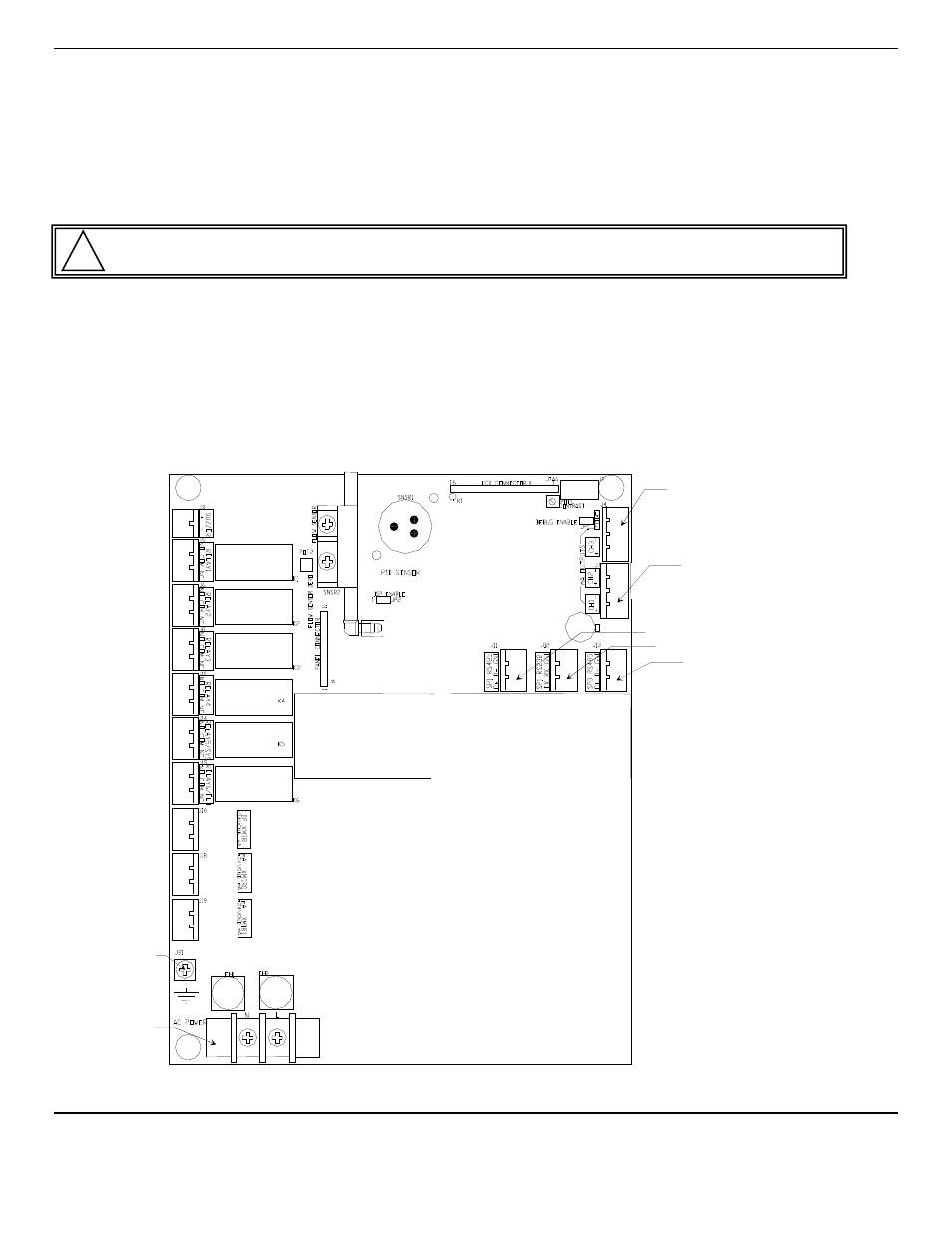

Page 9: Figure 2a: relay, input and output terminals

P

RO

A

IR

2200

ENMET Corporation

6

3.2 Sample Air Supply

Tap the pipe or tank containing the breathing air and use appropriate fittings to connect the sample input hose. The instrument

is designed to operate from an air supply pressure 55

PSIG

.

The sample air exits through the luer fitting(s) located on the bottom of the enclosure. See Figure 1. Take care not to obstruct

this exit port.

3.3 Power Supply

The input power can vary from 100 to 240

V

AC

, 50/60 Hz. Mains power should be connected to the Power Input Terminal

J23

and the ground screw

J21

. Se

e Figure 2 for location.

W

ARNING

:

Continuous gas detection and alarm systems become inoperative upon loss of primary power.

Upon supplying air and power to the instrument:

The green power on LED is lit.

The display backlight is lit, and instrument will step through a start-up sequence: unit serial number, software revision and

gases monitored may be shown on the display.

The instrument may go into alarm briefly, but the sensors stabilize quickly. If the instrument persists in alarm, acknowledge the

alarm by pressing the

AUDIO DEFEAT

/

ALARM ACKNOWLEDGE

switch. If alarm persists longer than 30 minutes, call

ENMET

customer service personnel.

3.4 Outputs

Two types of alarm outputs are available, relay contacts and 4-20mA outputs.

Figure 2A: Relay, Input and Output Terminals

Relay 1

Channel 1

Alarm 1

Relay 2

Channel 2

Alarm 1

Relay 3

Channel 3

Alarm 1

Relay 4

Channel 4

Alarm 1

Relay 5

Channel 1-4

Alarm 2

Relay 6

Ch 1-4 / System

Fault

Connector

Dew Point Sensor

Connector

4-20mA Input

Connector

4-20mA Input

Connector 2

Channel 3 & 4

4-20mA Output

Connector 1

Channel 1 & 2

4-20mA Output

Connector RS485

Connector RS232

Connector RS485

Ground Screw J21

Power Input

Terminal J23

!