Figure 7: connection of calibration gas cylinder – ENMET PROAIR 2200 User Manual

Page 29

P

RO

A

IR

2200

ENMET Corporation

26

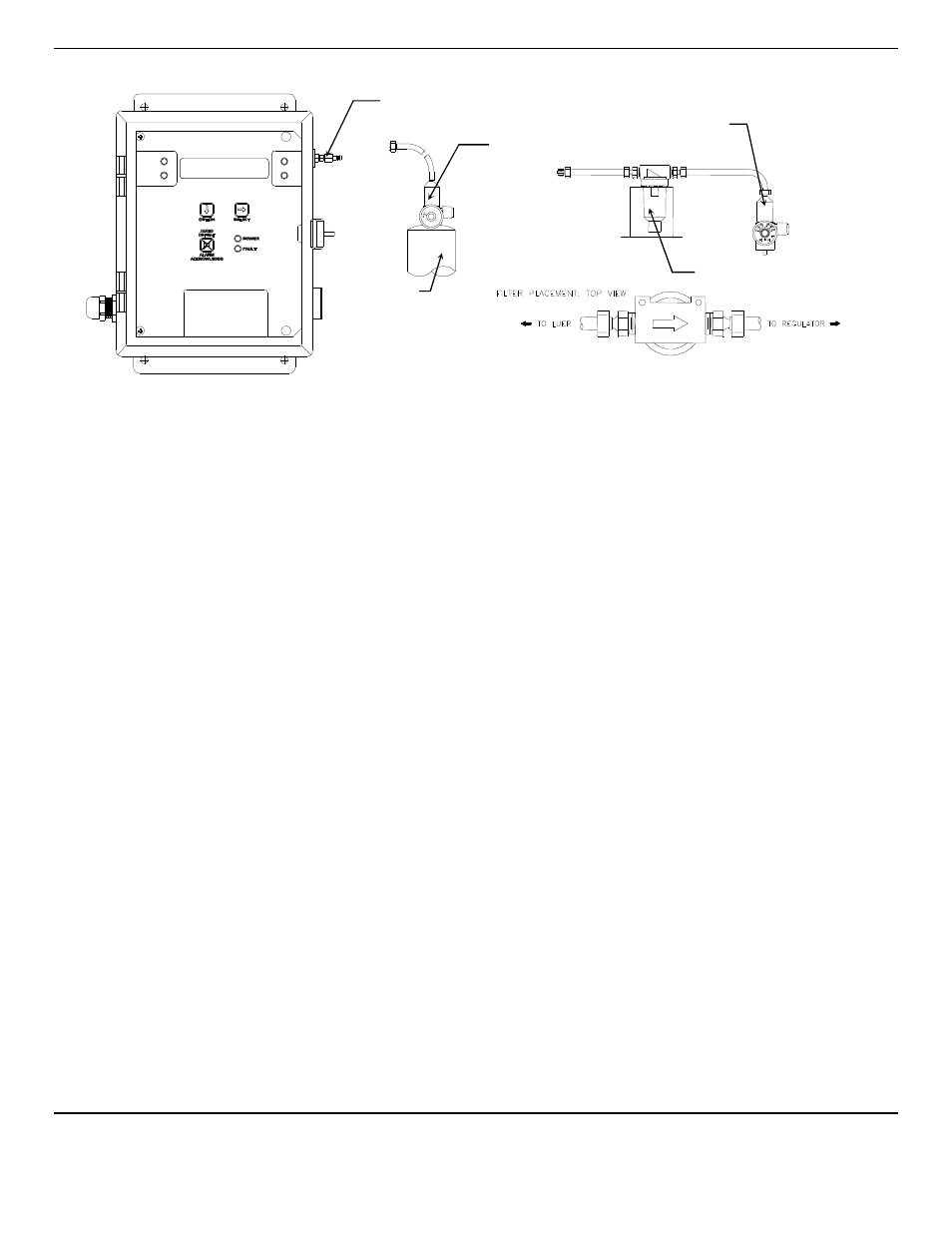

Figure 7: Connection of Calibration Gas Cylinder

Calibration Process for MOS Sensors

The following calibration procedure must be followed whenever a 60 series part number appear in the part number of the instrument,

examples 04652-6200-0000, 04652-7083-6000

Humidification is required when calibration is performed. In addition to the standard flow demand regulator, cylinder of calibration

gas you need

ENMET

humidifier assembly part number 037000-000

Fill the humidifier with clean water to about ¾ full, connect the flow demand regulator to one side of the humidifier and

connect the other side of the humidifier to the

P

RO

A

IR

2200

calibration/sampling port.

Warning: Be sure that the flow direction is correct, note the arrow on the humidifier, failure to do so will cause damage to the

P

RO

A

IR

2200

instrument

With the cylinder regulator and humidifier assembled follow the above steps to complete the calibration process

5.4.4

A Low Cal/ZeroCal Adjust

A Low Cal function should be performed only when the

P

RO

A

IR

2200

sensor are exposed to clean uncontaminated air. Use a

cylinder of 20.9% oxygen to provide a clean air reference if necessary. Attach the cylinder to the calibration adapter, attach the

adapter to the instrument and allow gas to flow over the sensor for up to 4 minutes.

Enter the maintenance menu by repeatedly pressing

OPTION

switch, until the maintenance menu is displayed. See

Figure 6,

P

RO

A

IR

2200

Maintenance Menu flow chart.

The first menu available is the Low Cal/ZeroCal.

Press the

SELECT

switch 4 times to perform a Low Cal.

If the Low Cal/ZeroCal is successful, The display will change to Hi Cal/SpanGas.

If you wish to Hi Cal/SpanGas the sensor apply calibration gas.

Proceed to gas calibration Section 5.3.1B

If you wish to Exit the maintenance menu, Press and

hold

OPTION

switch until the Maintenance Menu is displayed then

release. Then press

OPTION

switch until “Exit maint menu” appears and then press

SELECT

switch to return the instrument to

the Operational Display

An unsuccessful calibration will result in an error message being displayed,

Example:

Offset Err, Cal Slope Err If any Err

messages appear the channel needs to be re-calibrated. Repeat Section 5.3.1 Low Cal/ZeroCal Adjust making sure to use a

cylinder of 20.9% Oxygen.

Cylinder of Gas

Cylinder Valve

and Regulator

Calibration/Sample Port Fitting

Humidifier

Example of

Regulator