Trencher, Rt80q operator’s manual – Ditch Witch RT80 User Manual

Page 165

Service - 164

RT80Q Operator’s Manual

500 Hour

Trencher

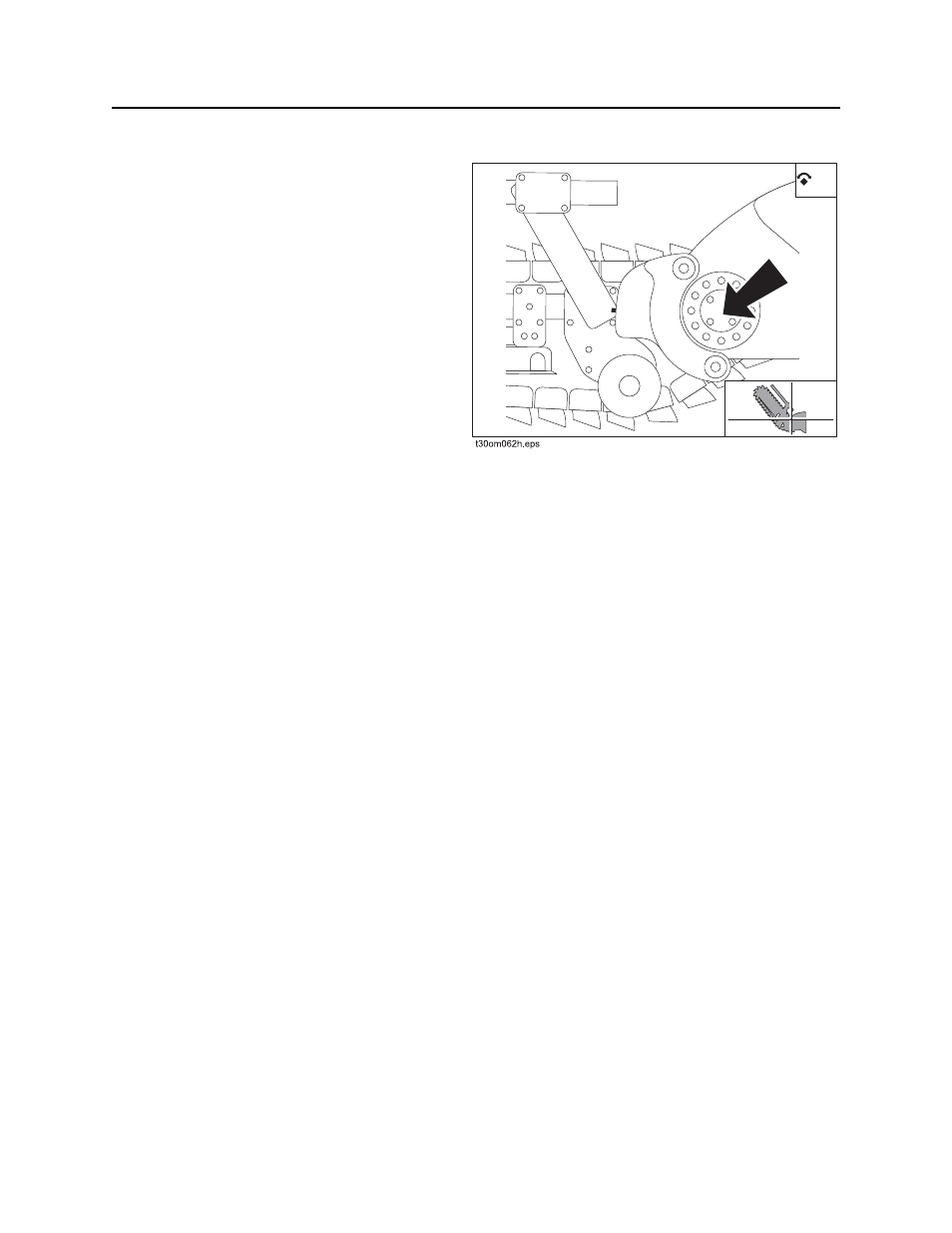

Adjust Headshaft Bearing

Adjust headshaft bearing every 500 hours.

To adjust:

1.

Remove cover. Remove bolts attaching

trenching attachment motor to gearbox.

2.

Remove bolt and washers in left end of

headshaft.

3.

Support gearbox with hoist and slide it off

headshaft.

4.

Install spacer (p/n 184-044) in place of

gearbox while checking bearings.

5.

Replace bolt on end of headshaft.

6.

Remove chain from headshaft sprocket.

7.

Turn chain sprocket until headshaft sprocket turns. When properly adjusted, it will take two hands and

some effort. If it turns easily, remove a shim.

See also other documents in the category Ditch Witch Special machinery:

- JT5 (161 pages)

- JT922 (159 pages)

- JT9 (165 pages)

- JT20 (195 pages)

- JT1220 (201 pages)

- JT2020 (203 pages)

- JT25 (203 pages)

- JT30 (245 pages)

- JT60 (218 pages)

- JT100 (243 pages)

- AT Air Hammer (11 pages)

- TK Series Manual (61 pages)

- 8500 (77 pages)

- MR90 (121 pages)

- FT5 (28 pages)

- FM5 (57 pages)

- FM13V (46 pages)

- FM25 (67 pages)

- P80 (71 pages)

- OnGrade (63 pages)

- FX20 (100 pages)

- FX25 (119 pages)

- FX30 (149 pages)

- FX50 (141 pages)

- FX60 (157 pages)

- MV800 (111 pages)

- RT Line (115 pages)

- RT30 (97 pages)

- RT45 (203 pages)

- RT55 (177 pages)

- RT100 (161 pages)

- RT115 (252 pages)

- RT120 (223 pages)

- Zahn (105 pages)

- RT115 Q (193 pages)

- RT120 Q (211 pages)

- 100SX (50 pages)

- 410SX (131 pages)

- SK350 (77 pages)

- SK750/SK755 (81 pages)

- SK850 (107 pages)

- SK850 Footings Machine (107 pages)

- 150RT (55 pages)

- 250RT (49 pages)