D. pilot – Bryant 376B User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

7. Remove eight screws that secure flue collector box to

center panel. Use care not to damage sealant.

8. Remove complete inducer assembly from furnace,

exposing flue openings.

9. Remove flue choke.

10. Using field-provided small wire brush, steel spring

cable, reversible electric drill, and vacuum cleaner;

clean cells.

a. Assemble wire brush and steel spring cable.

(1.) Use 4 feet of 1/4-in. diameter high-grade steel

spring cable (commonly known as drain

cleanout or Roto-Rooter cable).

(2.) Use 1/4-in. diameter wire brush (commonly

known as 25-caliber rifle cleaning brush).

NOTE:

The items called for in steps 1 and 2 can be pur

chased at a local hardware store.

(3.) Insert twisted wire end of brush into end of

spring cable, and crimp tight with crimping tool

or strike with baU-peen hammer. Tightness is

very important.

(4.) Remove metal screw fitting from wire brush to

allow insertion into cable.

b. Clean each heat exchanger cell.

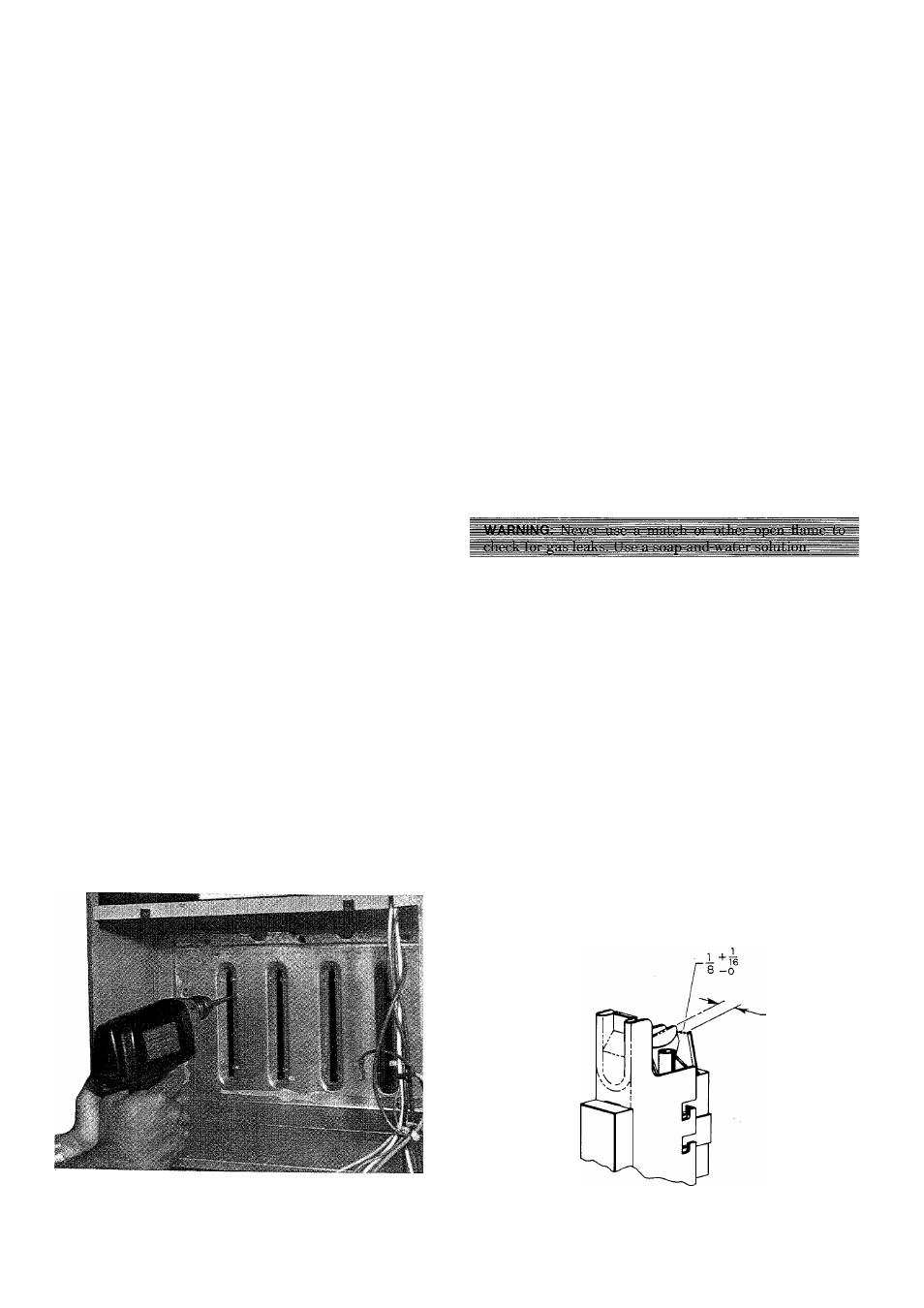

(1.) Attach variable-speed reversible drill to end of

spring cable (end opposite brush).

(2.) Insert brush end of cable into upper opening of

cell and slowly rotate with drill. Do not force

cable. Gradually insert at least 3 feet of cable

into two upper passes of cell. See Figure 18.

(3.) Work cable in and out of cell three of four times

to obtain sufficient cleaning. Do not pull cable

with great force. Reverse drill and gradually

work cable out.

(4.) Remove burner assembly and flame radiators.

(Identify gas valve leads.)

(5.) Insert brush end of cable in lower opening of

cell, and proceed to clean two lower passes of

cell in same manner as two upper passes.

(6.) Repeat the foregoing procedures until each cell

in furnace has been cleaned.

(7.) Using vacuum cleaner, remove residue from

each cell.

(8.) Using vacuum cleaner with soft brush attach

ment, clean burner assembly.

(9.) Reinstall flame radiators and burner assembly.

Care must be exercised to center the flame radi

ators in the cell openings. Refer to furnace wir

ing diagram when reconnecting gas valve leads.

11. After cleaning flue openings, check sealant on flue col

lector to ensure that it has not been damaged. If new

sealant is needed, contact your Distributor.

12. Reinstall flue choke. Be sure all screws are in place and

tight.

13. Clean and replace flue collector assembly, making sure

all eight screws are secure.

14. Replace four screws that secure the rehef box to blower

shelf.

15. Reconnect two wires to safeguard switch.

16. Reconnect wire harness edge connector to side of

inducer control box.

17. Reconnect vent pipe to relief box, reinstall pipe

enclosure.

18. Replace blower door only.

19. Turn on power and gas.

20. Set thermostat and check furnace for proper operation.

21. Check for gas leaks.

22. Replace control door.

D. Pilot

Check the pilot and clean if necessary at the beginning of

each heating season. The pilot flame should be high enough

for proper impingement of the safety element and to light

the burners. Remove the accumulation of soot and carbon

from the safety element or sensing probe. See Figure 19 and

check electrode position.

E. Electrica! Controls and Wiring

NOTE:

There may be more than one electrical supply to unit.

With power disconnected to unit, check all electrical connec

tions for tightness. Tighten aU screws on electrical connec

tions. If any smoky or burned connections are noticed, dis

assemble the connection, clean all parts and strip wire, and

reassemble properly and securely. Electrical controls are dif

ficult to check without proper instrumentation; therefore,

reconnect electrical power to unit and observe unit through

one complete operating cycle. If there are any discrepancies

in the operating cycle, contact your Dealer and request

service.

Figure 18—Cleaning Heat Exchanger Cell

A82181

^_T

16

Figure 19—Position of Electrode to Pilot

—8—