V. supply-air plenum installation (downflow), B. installation on a combustible floor – Bryant 376B User Manual

Page 2

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

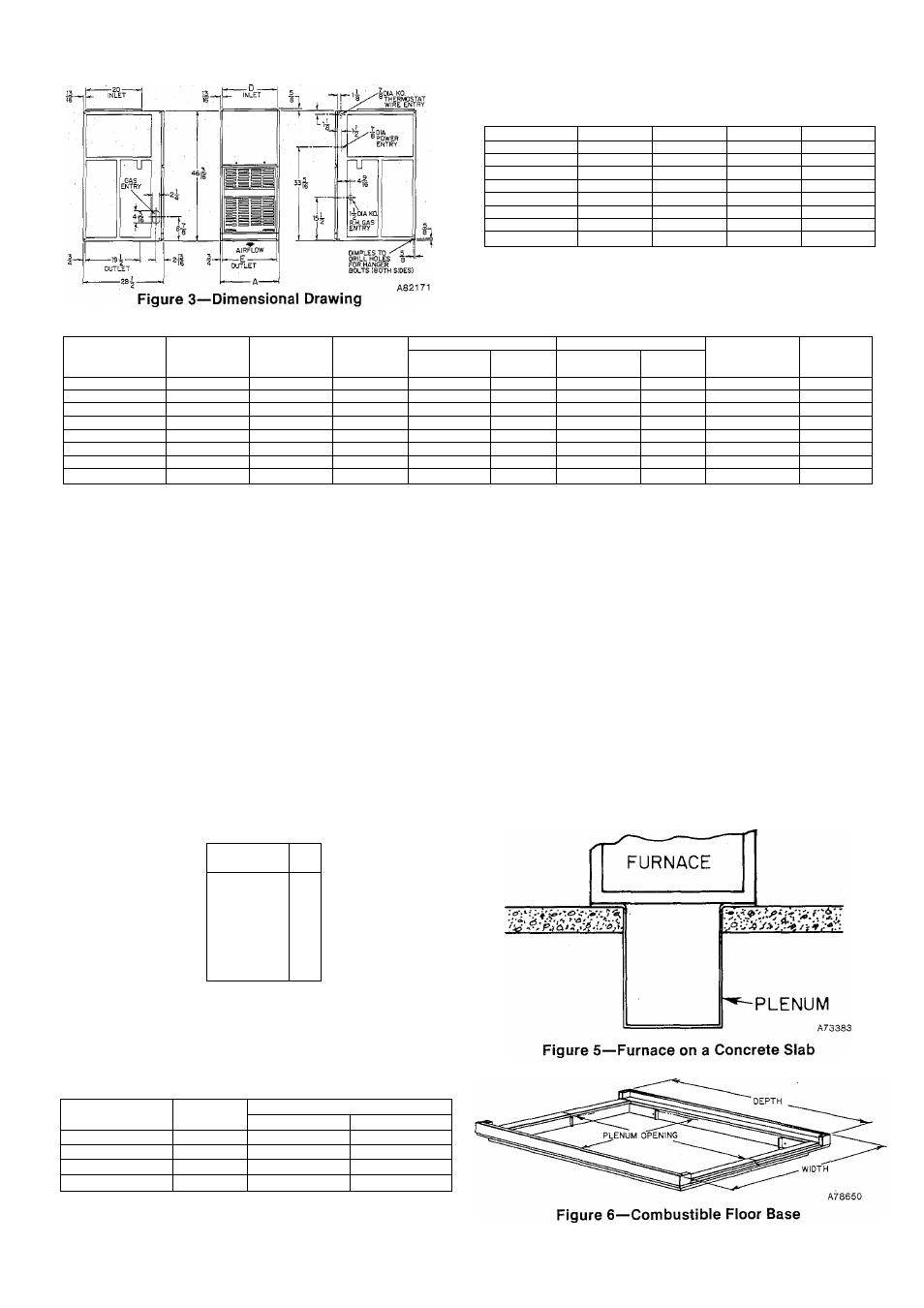

TABLE II—DIMENSIONS (In Inches)

Size

A

D

E

Vent Conn

024040

1 4-3/1 6

12-9/16

12-11/16

4

024055

14-3/1 6

12-9/16

12-11/16

4

036055

14-3/1 6

12-9/16

12-11/16

4

036075

17-1/2

1 5-7/8

16

4

048075

17-1/2

1 5-7/8

16

4

048095

17-1/2

1 5-7/8

16

4

060095

21

19-3/8

19-1/2

4

060115

24-1/2

22-13/16

23

5

TABLE III—RATINGS AND PERFORMANCE*

SIZE

Input

Buth*

Capacity

Buthtt

Temperature

Rise

Range

Heating

Cooling

Motor

HP & Type

Shipping

Weight

External Static

Pressure

Ft=/Min

External Static

Pressure

FCTMin

024040

48,000

39,000

50—80

0.10

610

0.5

Ш

1/5 Páó

130

024055

67,000

56,000

40—70

0.12

835t

0.5

890t

1/5 PSC

140

036055

67,000

56,000

35—65

0.12

1080

0.5

1157

1/3 PSC

142

036075

90,000

75,000

45—75

0.15

960t

0.5

1230t

1/3 PSC

160

048075

90,000

75,000

40—70

0.15

1240

0.5

1553

1/2 PSC

163

048095

114,000

95,000

55—85

0.20

1248

0.5 ■

1590

1/2 PSC

178

060095

114,000

95,000

55—85

0.20

1350

0.5

1929

1/2 PSC

188

060115

137,000

115,000

45—75

0.20

1037

0.5

2010

1/2 P$C

208

*The-above gas inputs are certified for altitudes to 2000 ft. For elevations above 2000 ft,

tDetermined by U.S. Government tests.

tTentative rating.

Installation comprises the following:

*1. Inspection

*11. Location, Ventilation, and Air for Combustion

*III. Gas Piping

*IV. Venting

V. Supply-Air Plenum Installation (Downflow)

VI. Attic Installation

VII. Crawl Space Installation

VIII. Filter Arrangement

IX. Sequence of Operation

X. Electrical Connections

XI. Startup and Adjustment

XII. Care and Maintenance

reduce.input 4% for each 1000 ft above sea level.

*To perform these sections (or installation steps), refer to

the appropriate sections of “Procedures for Induced-Com

bustion Gas-Fired Furnaces” booklet packaged with this

unit.

For accessory installation details, refer to applicable instal

lation literature.

V. SUPPLY-AIR PLENUM INSTALLATION (DOWNFLOW)

A. installation on a concrete slab

1. See Figure 3 for dimensions and location of supply-air

opening in furnace bottom.

2. Construct hole in floor per dimensions in Figure 4 and

Table IV.

3. Place plenum and furnace as shown in Figure 5.

B. Installation on a combustible floor

1. Read Installation Instructions packaged with combus

tible floor base.

HOLE IN

FLOOR

Ì

Figure 4—Floor Opening for Concrete Slab

TABLE IV—OPENING DIMENSIONS

Furnace Casing

Width

A

В

Heat-Oniy

Heat/Cooi*

14-3/16

13-1/8

19-5/8

20-15/16

17-1/2

16-7/16

19-5/8

20-15/16

21

1 9-7/8

19-5/8

20-15/16

24-1/2

23-7/16

19-5/8

20-15/16

*These dimensions apply when a Model 518A Evaporator Coil casing

is to be installed.

—2-