Viii. filter arrangement – Bryant 376B User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

above the louvered control panel. Extend the sheet metal

shield over the furnace top far enough to cover the gas pipe

entry hole.

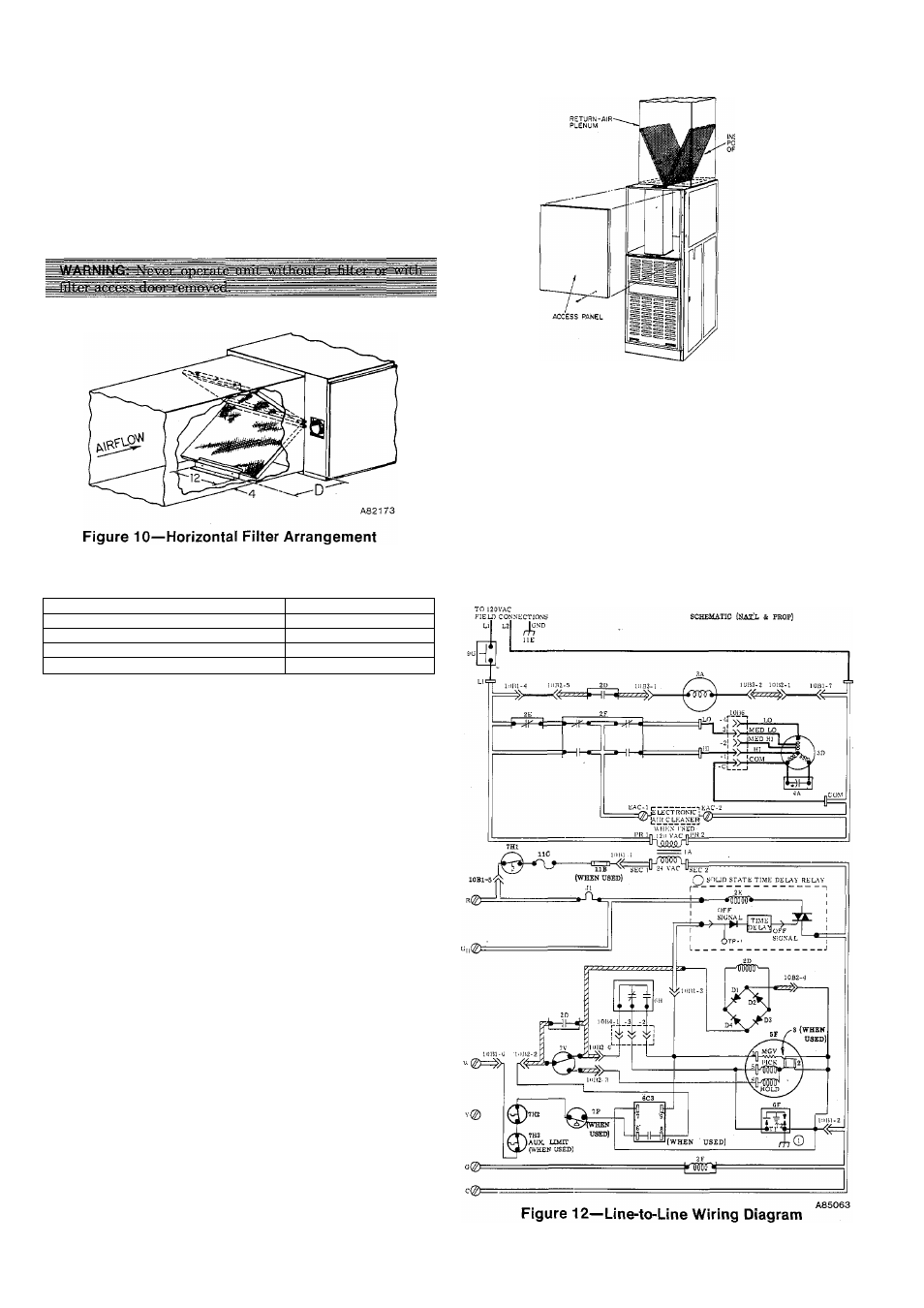

VIII. FILTER ARRANGEMENT

The two factory-supplied filters are shipped in the blower

compartment. After the return-air duct has been connected

to the furnace, install the filters in a V-formation inside the

return-air plenum. See Figure 10 and Table V for horizontal

applications. See Figure 11 for downflow applications.

TABLE V—FILTER RETAINER

Furnace Casing Width

0

1 4-3/1 6

15-3/16

17-1/2

14-1/2

21

13-9/16

24-1/2

12-1/4

LEGEND

lA-Transformer, 120-VAC/24-VAC

2D-Relay, Inducer Motor DPST-N. O.

2E-Relay, Heating Blower (HFR) SPST-N. C.

2F-Relay, Cooling Blower (CFR) DPDT

3A-Motor, Inducer

3D-Motor, Blower

4A-Capacitor, Run

5F-Valve, Gas (Redundant)

6C3-Lockout Module (When Used)

6F-Generator, Spark (Solid-State)

6H-Switch, Pilot-Flame Sensing SPOT

7H1-Switch, Limit SPST-N. C.

7H2-Switch, Draft Safeguard (SPST-N. C.) Manual-Reset

7H3-Switch, Auxiliary Limit (SPST-N. C.) Manual-Reset (When

Used)

7P-Pressure Switch-N.O.

7V-Switch, Flow Sensing SPOT

9G-Switch, Blower Door Interlock SPST-N. O.

10B1-Connector, Edge (Furnace Control Board)

10B2-Connector, Edge (Inducer Control Board-7 CKT)

10B3-Connector, Edge (Inducer Control Board-2 CKT)

10B4-Connector, Pilot

10B5-Factory Test Points

10B6-Connector, Blower Motor

11B-Fuse, In Line 2 Amp (When Used)

11C-Link, Fusible (Overtemperature)3 Required

11E-Ground, Equipment

TP-1-Test Point

0

Factory Wiring, 120-VAC

Factory Wiring, 24-VAC

Conductors on 6C1 (Furnace Control Board)

Conductors on 6C2 (Inducer Control Board)

Screw Terminal for Field Wiring

1/4-inch Quick-Connect Terminals

Figure 11—Position of Filters

IX. SEQUENCE OF OPERATION

Using the schematic wiring diagram, Figure 12, trace the

sequence of operation for the heating cycle is as follows;

1. When the blower door is in place, 120 volts is supplied

through blower door interlock switch 9G. Transformer

lA is energized, supplying 24 volts to heating-blower

relay coil 2E, which opens normally closed blower relay

contacts 2E in the low-speed circuit of blower motor

3D.

-4—