Bryant 376B User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

2. The wall thermostat “calls for heat,” closing the R and

W circuit. This closed circuit supplies power to the 24-

volt safety circuit containing Hmit switch 7H1, fusible

link lie, manual-reset draft-safeguard switch 7H2, and

manual reset auxiliary switch 7H3.

3. Simultaneously, the pick coil of gas valve 5F, spark

generator 6F, and inducer-motor relay coil 2D are ener

gized. Inducer-motor relay contacts 2D in the 120-volt

circuit close, starting inducer blower motor 3A. Also,

another set of contacts in inducer-motor relay 2D close

in the 24-volt circuit, and lock in inducer-motor relay

coil 2D. The coil is locked in until the R and W circuit

or safety circuit opens.

4. When the pick coil of gas valve 5F is .energized, gas

flows to the pilot. The pilot gas is ignited by a spark

produced by spark generator 6F. Simultaneously,

inducer motor 3A comes up to speed, actuating flow

sensing switch 7V, energizing the hold coil of gas valve

5F. The pick coil of gas valve 5F and spark generator

6F are deenergized when the contacts of pilot-flame

sensing switch 6H move from the normally closed posi

tion, breaking the circuit to the pick coil and spark gen

erator. In approximately 50 to 60 seconds, the nor

mally open pilot-flame sensing contacts close, making

the circuit to the MGV (Main Operator) of gas valve

5F. Gas valve 5F opens in approximately 10 seconds,

allowing gas flow to the main burners, which are

ignited by pilot 6H. Simultaneously, time-delay circuit

IIL in the blower control center is energized. Approxi

mately 50 seconds after gas valve 5F opens, heating

relay coil 2E is deenergized, which closes the 120-volt

contacts of heating relay 2E, starting blower motor 3D

on its heating speed.

5. When the thermostat is satisfied, the circuit between R

and W is broken, deenergizing gas valve 5F, inducer

motor relay 2D, and the solid-state time-delay circuit

on the printed-circuit board. The gas flow stops imme

diately to the pilot and main burners. After approxi

mately 105 seconds, heat relay 2E is energized and

blower motor 3D stops.

NOTE:

After a brief interruption of either electric or gas sup

ply, the furnace will not resume operation until the contacts

of pilot-flame sensing switch 6H move from the normally

open to the normally closed position.

Cooling Cycle

1. The wall thermostat “calls for cooling.”

2. The R, G, and Y circuits are energized. Simultaneously,

the R-and-Y circuit starts the outdoor condensing unit,

and the R-and-G circuit energizes cooling relay coil 2F,

which closes normally open contacts 2F, energizing the

cooling speed winding of motor 3D and opening the

normally closed contacts of cooling relay 2F.

X. ELECTRICAL CONNECTIONS

A. Line-Voltage Wiring

IMPORTANT: Before proceeding with the electrical con

nections, make certain that voltage, frequency, and phase

correspond to that specified on the unit rating plate. Also,

check to be sure that the service provided by the utility is

sufficient to handle the additional load imposed by this

equipment. Refer to the unit rating plate for equipment elec

trical requirements.

in accordance with the National Electrical Code and any

local codes or ordinances that might apply.

Use a separate fused branch electrical circuit containing a

properly sized fuse or HACR-type circuit breaker for this

furnace. A disconnecting means must be located within

sight of, and readily accessible to, the furnace. The blower

door switch may be acceptable in some areas as a discon

necting means.

If fine-voltage wiring to the unit is encased in a nonmetalfic

sheath, connect the incoming ground wire to the grounding

wire inside the furnace J-box. If metallic conduit is used, it

will serve as the ground.

B. Low-Voltage Wiring

Make field low-voltage connections at the low-voltage termi

nal strip. See Figure 15.

NOTE:

When the furnace is instedled in the horizontal posi

tion with RH discharge air, low-voltage wire connections

can be made easier by removing the two control box mount

ing screws and letting the control box turn so that the low-

voltage screw terminals are visible. Be sure to reinstall the

control box after the connections are made.

NOTE:

Use AWG No. 18 “color-coded” copper thermostat

wire for lengths up to 100 ft. Above 100 ft, use AWG No. 16

wire.

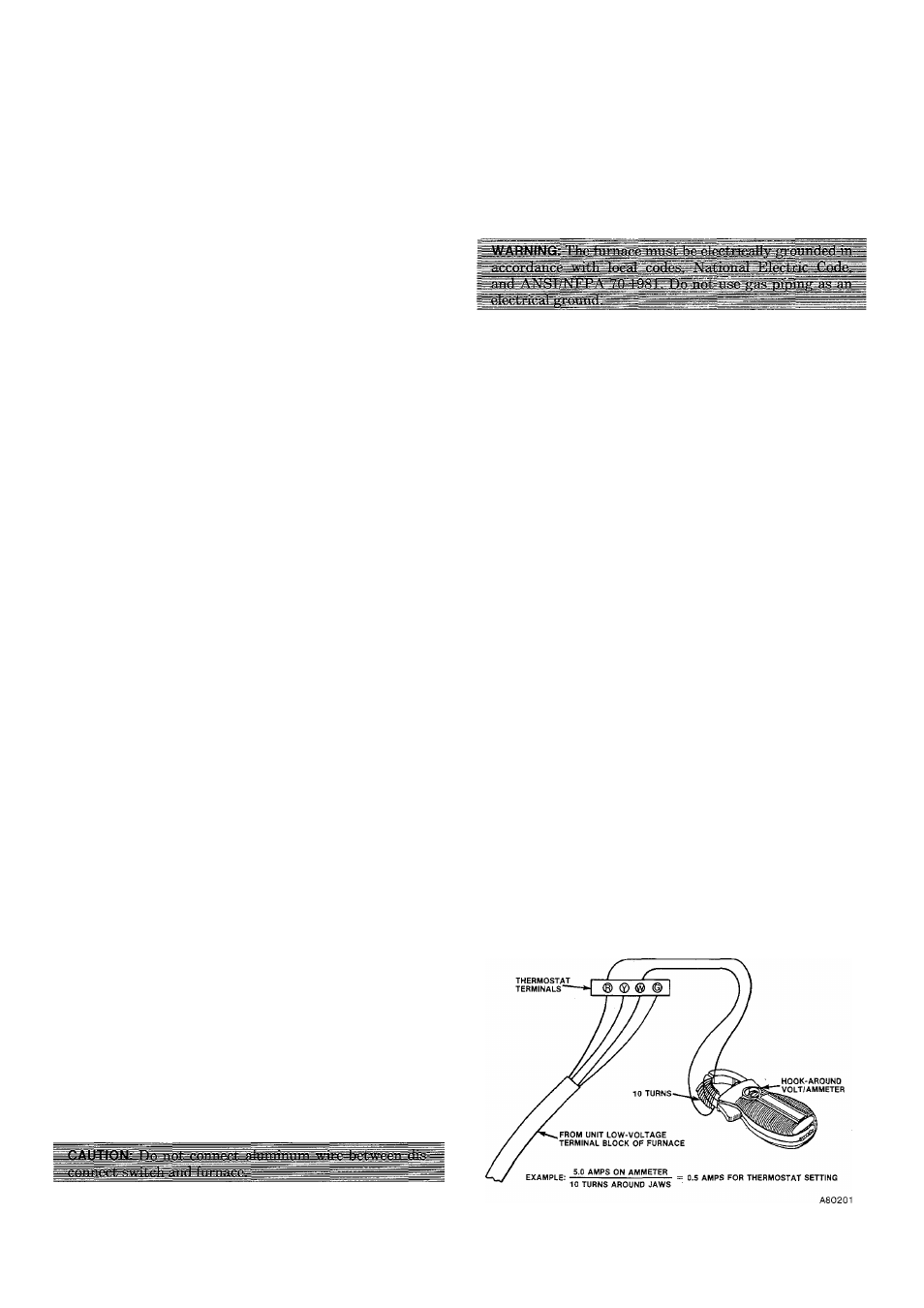

IMPORTANT:

The thermostat heat anticipation must be set

to match the amp draw of the gas valve and electrical com

ponents in the R-W circuit. Accurate amp draw readings

can be obtained at thermostat subbase terminals R & W.

Figure 13 illustrates an easy method of obtaining the actual

amp draw. The amp reading should be taken after the

blower motor has started.

The room thermostat should be located where it wfll be in

the natureJ circulation path of room air. Avoid locations

where the thermostat would be exposed to cold-air infiltra

tion, drafts from windows, doors, or other openings leading

to the outside, or exposed to air currents from warm- or

cold-air registers; or to exposure where the natural circula

tion of the air is cut off—such as behind doors, above or

below mantels, shelves, etc.

The thermostat should not be exposed to heat from nearby

fireplaces, radios, televisions, lamps, or rays from the sun.

Nor should the thermostat be mounted on a wall containing

pipes or warm-air ducts, or a flue or vent that could affect

its operation and prevent it from properly controlling the

See Figure 15 for wiring diagram showing the proper field

high- and low-voltage wiring. Make all electrical connections

Figure 13—Amp Draw Check With Ammeter

—5—