Unit disassembly, Tools needed, Remove front panel – Carrier P User Manual

Page 3: Disconnect power for cord-connected unit

3

UNIT DISASSEMBLY

This section includes common procedures for disas-

sembly and re-assembly of unit.

TOOLS NEEDED

The following field-supplied items are recommended

for general disassembly of the unit:

• Flat head screw driver

•

5

/

16

-in. nut driver

• Safety glasses

• Needle nose pliers

REMOVE FRONT PANEL

NOTE: Before removing front panel, remove 2 locking

screws (if installed) located behind the filter handles.

See Figure 3. If a lateral duct accessory is installed, the

plenum must be removed before removing the front

panel. Refer to Remove Lateral Duct Extension section

for removal instructions.

1. Grasp the front firmly near bottom of both sides.

2. Pull the panel forward then upward to release

magnetic latches and partition hooks. See Figure 4.

DISCONNECT POWER FOR

CORD-CONNECTED UNIT

1. Turn selector switch to OFF position.

2. Open the disconnect switch at main power supply.

Use proper Lockout and Tag procedures.

3. Unplug the unit service cord.

DISCONNECT POWER FOR

PERMANENTLY CONNECTED

(HARDWIRED) UNITS

1. Turn selector switch to OFF position.

2. Open the disconnect switch at main power supply.

Use proper Lockout and Tag procedures.

3. Remove screw from access cover and remove

access cover.

4. Pull out the plug assembly and disconnect. See

Figure 5.

IMPORTANT: Follow manufacturer’s instruc-

tions when disassembling and re-assembling a

unit for cleaning, maintenance, or part replace-

ment. When disassembling wiring, it is strongly

recommended that numbered stickers be

attached to identify leads and terminals to aid in

the re-assembly process. Always review safety

procedures prior to the start of a job.

Prior to servicing electrical equipment, discon-

nect all power to avoid electric shock! Tag all dis-

connects. Never alter cord or plug and do not use

extension cords.

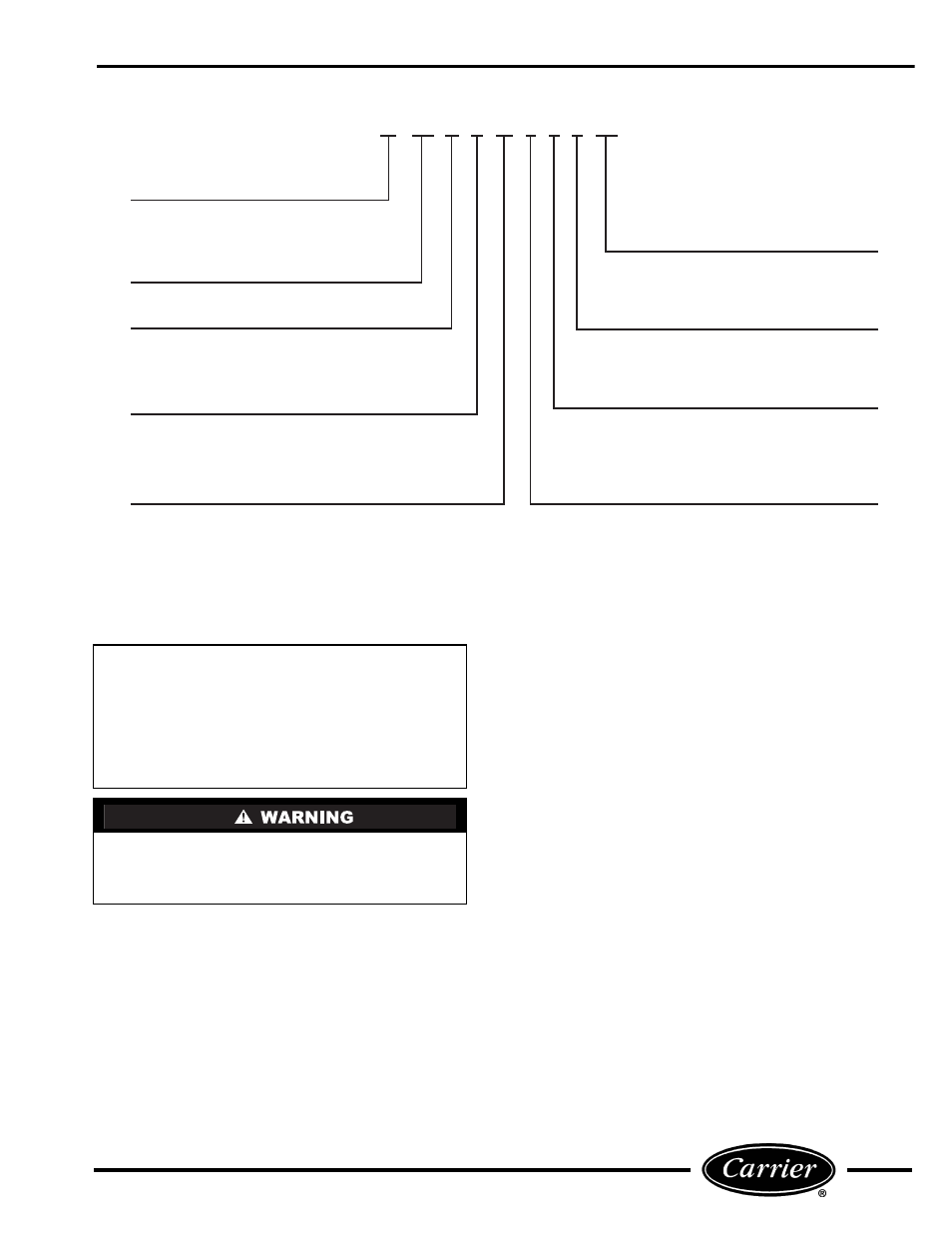

Electrical Data

3 – 230/208-v, 60 Hz

4 – 265-v, 60 Hz

Cooling Capacity (nominal)

07 – 7,000 Btuh

09 – 9,000 Btuh

12 – 12,000 Btuh

15 – 15,000 Btuh

52 PQ A 3 12 3 0 1 AA

Series Designation

PTAC (Packaged Terminal Air Conditioner)

Non-Performance

Changes 0-9

Chassis Options

Blank or AA – Standard

CP – Corrosion Protection

RC – Wall Thermostat Control

RP – Wall Thermostat Control with

Corrosion Protection

CE – Cooling with Electric Heat

CQ – Heat Pump with Electric Heat

PC – Cooling Only

PE – Cooling with Electric Heat

PQ – Heat Pump with Electric Heat

Packaging

1 – Domestic

Latest Revision

A – Z

Electric Heater Size

0 – No Heating (Cooling Only Model)

2 – 2.3 kW

3 – 3.4 kW

5 – 5.0 kW

FIGURE 2 — MODEL NUMBER NOMENCLATURE