Compressor replacement – Carrier P User Manual

Page 15

15

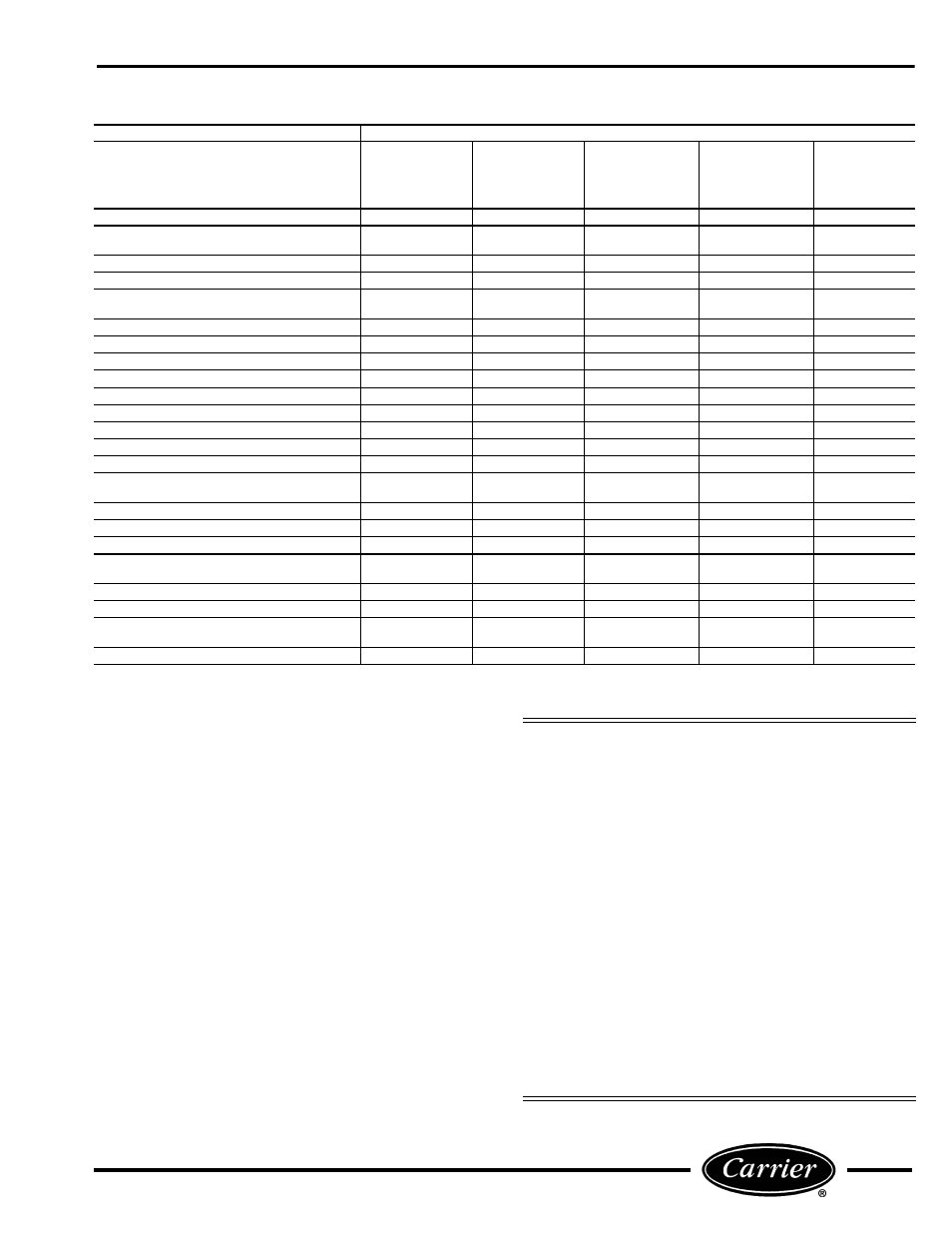

FIGURE 29 — BASIC COMPRESSOR TROUBLESHOOTING GUIDE

5. Next, perform a grounded windings test to test

the resistance individually of each wire to the

shell of the compressor. The paint on the compres-

sor can prevent good contact between the probe

and the metal. The paint should be removed from

a small section of the shell of the compressor to

ensure good contact by the meter probe. The volt-

ohmmeter should be set to at least the 100X ohm

level. The measured resistance between each wire

and ground should be infinite or O.L. on the

readout. If there is measurable resistance one of

the windings is likely shorted to ground. See

Figure 31.

6. A compressor that has a winding to winding short

or a winding to compressor shell short is electri-

cally failed and needs to be replaced. See the

Compressor Replacement section for details.

COMPRESSOR REPLACEMENT

Before working on the compressor, read the instruc-

tions thoroughly and gather the necessary tools for the

job. Review all safety information on unit and in liter-

ature. Always turn off all power to unit to avoid the

possibility of electrical shock.

POSSIBLE CAUSE

SYMPTOM

COMPRESSOR

STARTS AND

RUNS BUT

CYCLES ON THE

OVERLOAD

COMPRESSOR

STARTS AFTER

CYCLING THE

OVERLOAD

SEVERAL TIMES

COMPRESSOR

WILL NOT

START. IT HUMS

AND CYCLES ON

THE OVERLOAD

COMPRESSOR

WILL NOT START

AND MAKES NO

NOISE

COMPRESSOR

CYCLES OFF

(NOT ON

OVERLOAD)

COILS/FILTERS DIRTY OR PLUGGED

X

AIR OR NONCONDENSABLE GASES

IN SYSTEM

X

X

SYSTEM REFRIGERANT OVERCHARGED

X

X

DISCHARGE LINE RESTRICTED

X

X

CAPILLARY TUBE OR STRAINER

RESTRICTED OR PLUGGED

X

X

X

FAN BLADE OR MOTOR DEFECTIVE

X

X

FAN BLADE OR BLOWER WHEEL STUCK

X

X

SYSTEM REFRIGERANT UNDERCHARGED

X

X

EVAPORATOR AIRFLOW RECIRCULATION

X

UNIT OVERSIZED FOR APPLICATION

X

COMPRESSOR REQUIRES START ASSIST

X

X

NO POWER TO UNIT

X

LOW VOLTAGE TO UNIT

X

X

X

X

OVERLOAD PROTECTOR OPEN

X

OVERLOAD PROTECTOR INCORRECT

OR DEFECTIVE

X

X

X

CAPACITOR INCORRECT OR DEFECTIVE

X

X

X

X

THERMOSTAT CONTACTS ARE OPEN

X

THERMOSTAT IS SET TOO HIGH OR LOW

X

SELECTOR SWITCH IS OPEN

OR DEFECTIVE

X

WIRING IS INCORRECT OR DEFECTIVE

X

X

X

X

SYSTEM PRESSURES NOT EQUALIZED

X

X

X

COMPRESSOR MOTOR OR

MECHANISM DEFECTIVE

X

X

X

X

X

COMPRESSOR GROUNDED

X

Consider the following safety issues before

beginning:

• New and unfamiliar tasks should be performed

under the supervision of an experienced service

technician.

• Personal protective equipment, such as work gloves

and safety glasses, should be worn.

• The floor around the work area should be clean and

free of debris.

• Make sure tools are the correct tools for the job and

that they are working properly and in good condition.

• Never replace a blown fuse without correcting the

cause of the original failure. If thermally operated

circuit breakers or overloads are tripping, make

sure the trip is not due to excessively high tempera-

tures or loose connections.

• When brazing suction and discharge lines, cool the

lines with a damp, clean cloth to prevent injury.

• Oil may be present in the compressor accumulator

and interconnecting tubing. Use caution when

removing tubing.