American Dryer Corp. AD-400 User Manual

Page 18

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

The gas dryer piping installation must meet the National Fuel Gas Code ANSI Z223.1- (latest edition), as

well as local codes and ordinances and must be done by a qualified technician.

Pipe joint compounds that resist the action of natural and LP. gas MUST be used.

Test all pipe connections for leaks by brushing on a soapy water solution. NEVER TEST FOR LEAKS

WITH A FLAME.

4. Exhaust Air Ducting

The dryer's exhaust air must be vented to the outdoors by the shortest route possible with the number of

elbows kept to a minimum. The duct work should be designed and installed by qualified technicians.

Improperly designed duct work may reduce the airflow through the dryer, causing improper and unsafe

drying conditions. The static pressure of the exhaust air in the duct work must not exceed 1J25 inches

water column (3.1 millibar). The dryer exhausts 4,500 cfm of air during the drying cycle.

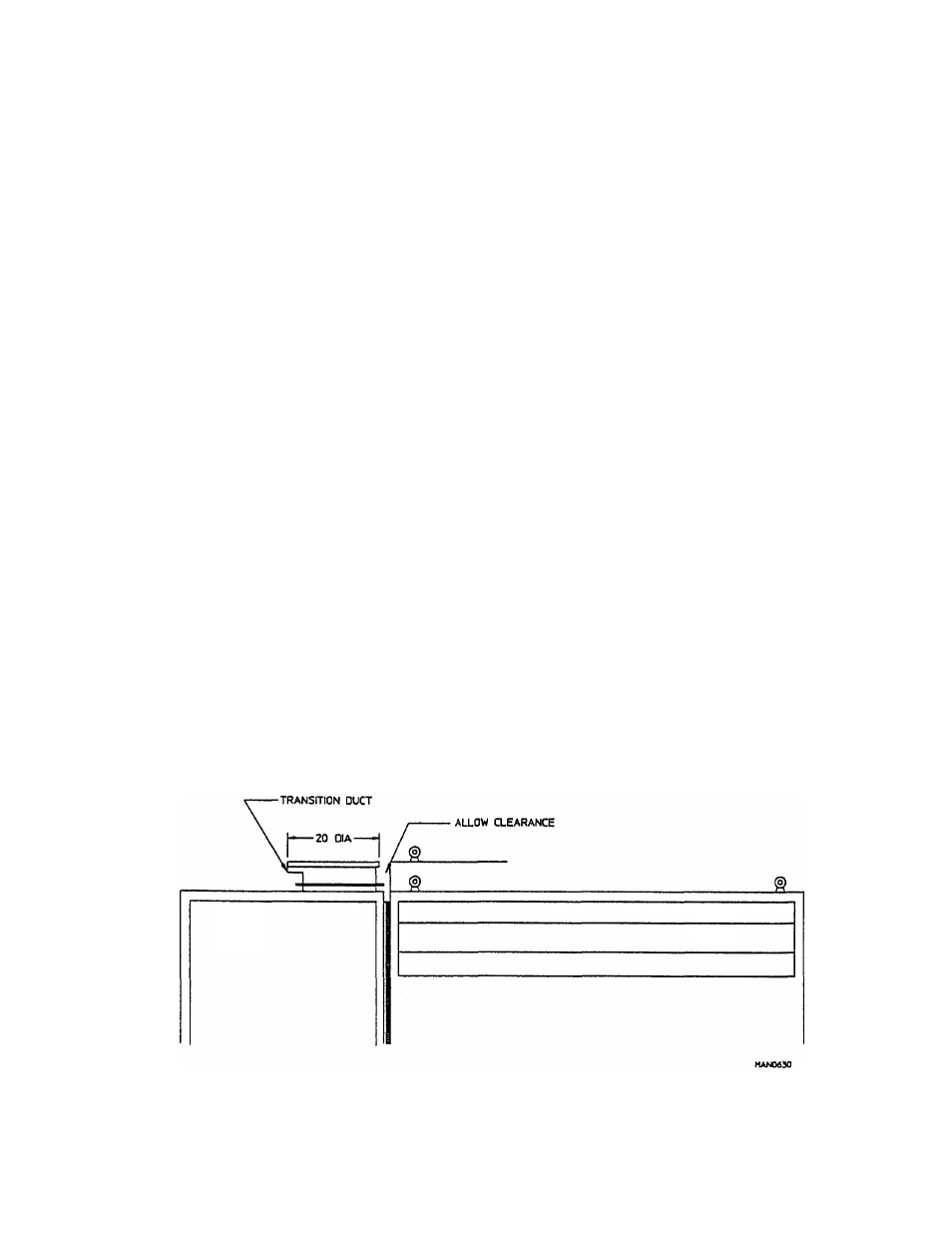

The exhaust vent connection is located on top of the bumer/heater section of the dryer. It has a

rectangular cross-section and is flanged.

The duct work connecting the vent to the outdoors must be a minimum of 20 inches in diameter for a

round duct or 324 square inches for a rectangular duct (18 inches by 18 inches square duct would be

sufficient).

A sheet metal transition piece is supplied to connect the 20-inch diameter exhaust duct to the dryer's

exhaust vent connection. Care must be taken in locating this transition piece so that the tilting tumbler

section does not hit the transition piece.

16