Trouble shooting chart for recoil start models – Bolens 130-360A User Manual

Page 15

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

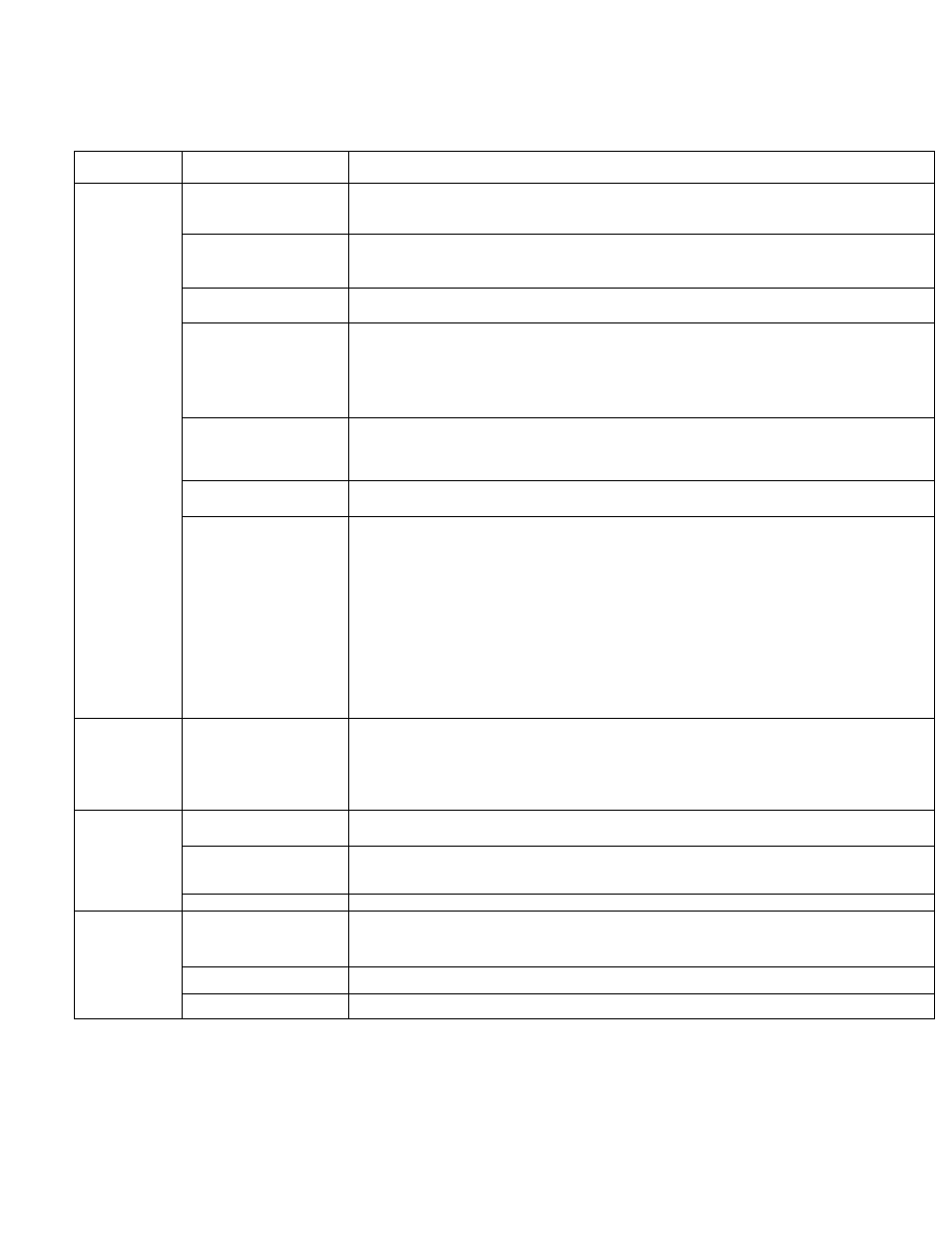

TROUBLE SHOOTING CHART FOR RECOIL START MODELS

CAUTION; ALWAYS DISCONNECT SPARK PLUG BEFORE ATTEMPTING ANY REMEDY.

TROUBLE

LOOK FOR

REMEDY

Engine will not

start when re

coil handle is

Clutch and blade

not disengaged.

Clutch pedal must be depressed and blade must be shut off.

pulled.

Ignition key not

in the ON position.

Turn on the ignition key.

Throttle not in the

starting position.

Check owner’s guide for correct position for throttle control for starting.

No spark to spark plug.

Spark plug lead disconnected. Connect lead.

Hold

spark

plug

lead

away

from

engine

block

about

1/8".

Crank

engine.

There

should

be

a

spark. If not, have the engine repaired at authorized engine service dealer.

Faulty

spark

plug.

To

test,

remove

spark

plug.

Attach

spark

plug

lead

to

spark

plug.

Ground

spark

plug

body

against

the

engine

block.

Crank

the

engine.

The

spark

plug

should

fire

at

the

electrode. Replace if it does not.

No fuel to the carbure

tor.

Gasoline tank empty. Fill.

Fuel valve shut off. Open valve. Valve is located either at the bottom of the fuel tank or on the

carburetor.

Fuel line is plugged. Remove and clean.

Air filter dirty.

If the air cleaner is dirty, the engine may not start. Clean or replace as recommended by the en

gine manufacturer.

Mechanical failure

(wires or switch).

The

interlock

system

includes

two

mechanical

activated

switches

which

are

wired

in

parallel.

If

the

buttons

on

both

switches

are

not

depressed

at

least

1/8",

the

magneto

will

be

grounded

and

the

engine

will

not

start.

While

testing

the

interlock

system,

you

will

make

the

mower

temporarily

unsafe

by

permitting

the

engine

to

be

started

with

the

blade

and

clutch

engaged.

WARNING:

While

testing,

disengage

the

clutch,

shut

off

the

blade

control,

set

the

parking

brake

and

place

the

gear

shift

lever

in

neutral.

Disconnect

the

yellow

wire

where

it

attaches

to

the primary wire from the breaker assembly on the engine. Try to start the engine. If the

engine

does not start,

the problem is in the engine (e.g. no fuel or no ignition). If the engine does start,

the

problem

is

in

the

safety

system.

Check

the

following:

1.

The

interlock

wire

may

be

ground

ed by

being pinched or

rubbing

through the

insulation. Tape or

replace the

wire. 2. The bolt on

the

flat

spring

behind

the

recoil

starter

where

the

yellow

wire

attaches

must

be

insulated

from

the

spring.

Use

a

continuity

tester.

If

it

is

not

insulated,

remove

the

bolt

and

nut,

and

replace

the two fiber washers and reassemble.

Engine stops

when the mow

er blade is en

gaged or the

clutch is re

leased.

Recoil handle is not

in proper position.

After

the

engine

starts,

the

recoil

starter

handle

must

be

pushed

into

the

dashboard

and

turned

a quarter turn either direction to lock it in place.

Engine

smokes.

Engine loses crankcase

vacuum.

Dipstick not seated or broken. Replace defective part.

Engine breather defective. Replace.

Excessive

vibration

Bent or damaged blade

spindle

Stop engine immediately.

Check all pulleys, blade spindles, blade adapters, keys and bolts for

tightness or damage.

Tighten or replace any damaged parts.

Bent blade.

Stop engine immediately.

Replace damaged blade. Only use original equipment blades.

Mower will

not discharge

grass or leaves

uncut strips.

Engine speed too low.

Throttle must be set between 3/4 and full throttle.

Transmission selection.

Use lower transmission gear. The slower your ground speed, the better the quality of cut.

Blades short or dull.

Sharpen or replace blades (uncut strip problem only).

15