Engine air cleaner, Clean air intake screen, Engine spark plugs – Generac Power Systems Air-cooled Recreational Vehicle Generator 9734-3 User Manual

Page 14

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Generac NP^6tt?G ftecreational \M«cle Genwator

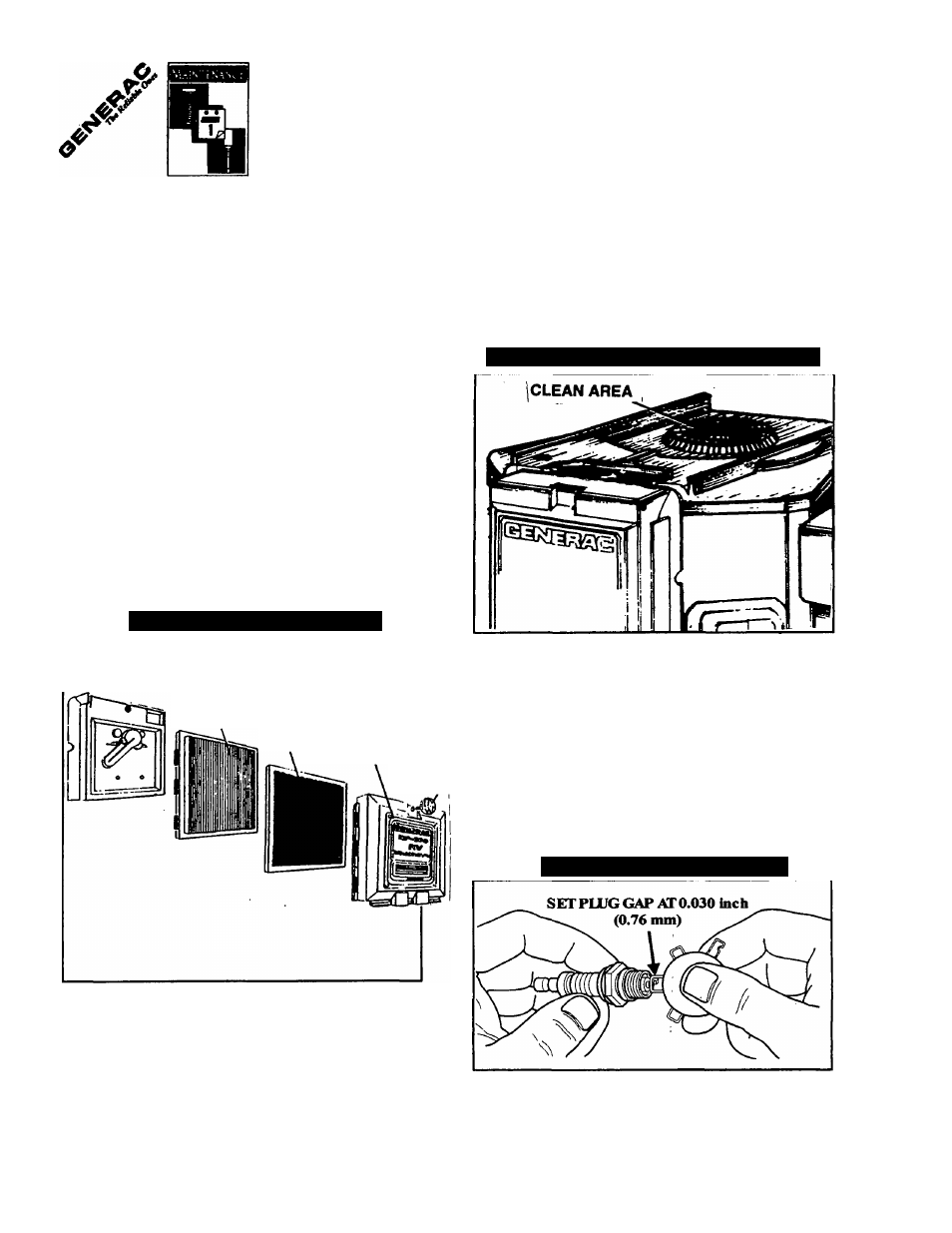

ENGINE AIR CLEANER

Clean and re-oil the foam pre-cleaner every three months or

ever 25 hours of operation, whichever occurs first. Service

the foam pre-cleaner more frequently if you operate the gen

erator in extremely dusty or diiiy conditions (Rgure 10):

• Turn KNOB counterclockwise to loosen.

• Remove COVER, FOAM PRE-CLEANER and PAPER

FILTER.

• Remove foam pre-cleaner from cover

• Wash foam pre-cleaner in liquid detergent and water.

• Wrap foam pre-cleaner in a cloth and squeeze dry.

• Saturate foam pre-deaner in engine oil. Squeeze to remove

excess oil and to distribute oil.

• Install foam pre-cleaner into cover, followed by paper filter.

Tabs at edges of paper fitter must lock into slots on cover.

Once each year or every 100 operating hours (whichever

comes first), replace the paper filter. The new replacement

filter must be a flame retardent type.

Figure 10 — Engine Air Cleaner

CLEAN AIR INTAKE SCREEN

Clean all foreign material from the air intake screen (Figure

11) at lease once every 100 hours of operation. Clean more

often if necessary.

*

Inspect the area around the generator exhaust muffler peri

odically and remove all grass, leaves, dirt, etc. from this area.

Figure 11 — Cleaning Air Intake Screen

PAPER

FILTER

FOAM

PRE

CLEANER

COVER

KNOBl

ENGINE SPARK PLUGS

Clean each engine spark plug and set gaps4o 0.030 inch

(0.76mm) every 100 hours of operation (Figure 12). Clean by

scraping or wire brushing and washing with commercial sol

vent. DO NOT BLAST CLEAN SPARK PLUGS.

CAUTION: Sparking can occur if wire terminal

does not fit firmly over spark plug terminal end. If

necessary, reform wire terminal to obtain a tight fit

Figure 12 — Engine Spark Plug

R e c r e a t i o n a l V e h i c l e G e n e r a t o r

14