Wheel speed lever, Tines/pto clutch lever, Depth regulator lever – Troy-Bilt 12204-10HP User Manual

Page 14: Handlebar height adjustment lever, Wheel speed lever tine/pto clutch lever

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section 3: Features and Controls

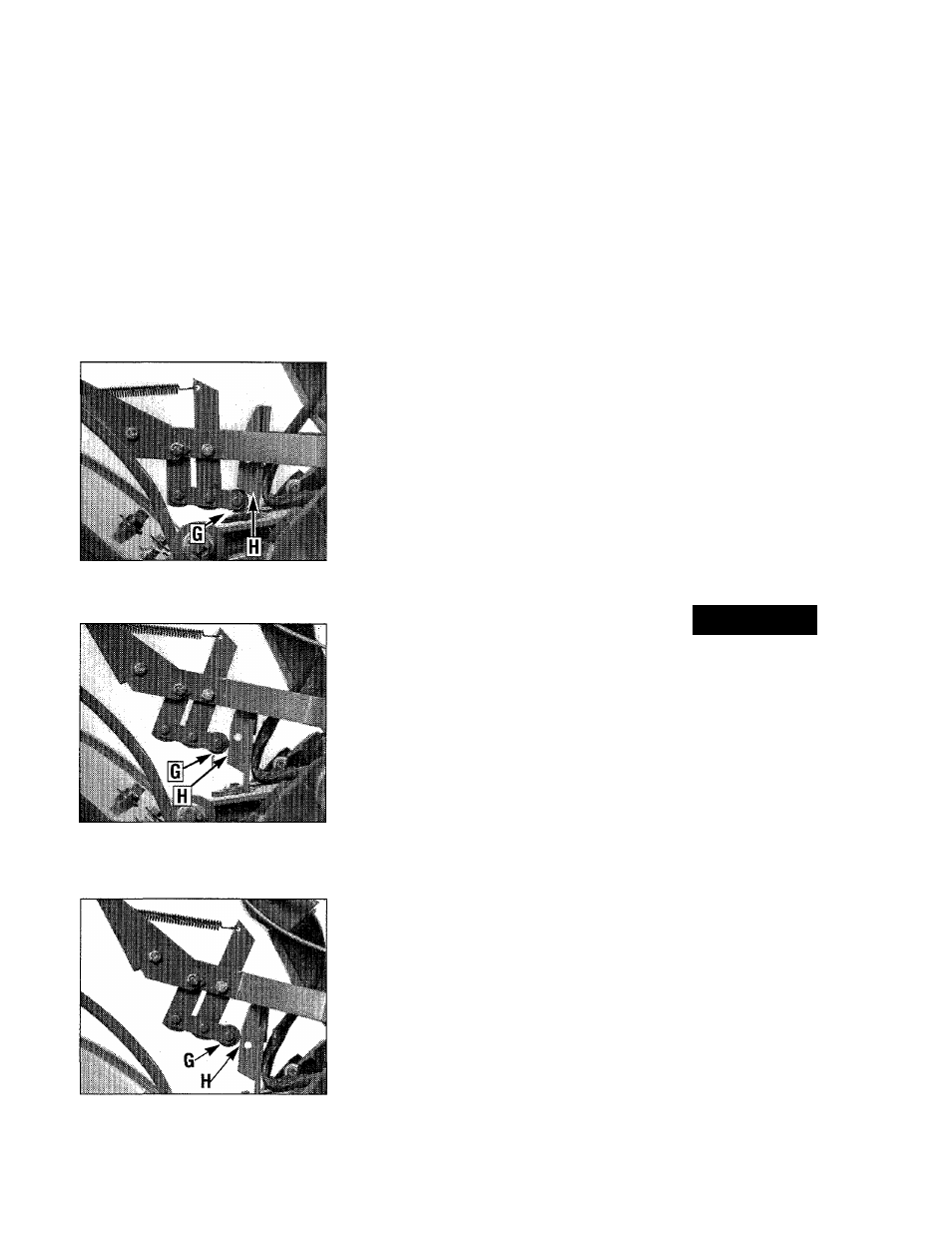

Verify Position of Clutch Roller

When you shift bet\veen FORWARD,

NEUTFtAL and REVERSE the clutch

roller

at

the

base

of

the

WhecIs/Tines/PTO Drive Lever should

be positioned as shown in Figures 3-2.

3-3 and 3-4. Verify the position of the

clutch roller as you shift the lever. If it

is not positioned correctly, contact the

Factory or see your local authori

7

ed

dealer.

Figure 3-2: FORWARD position; rc^ler

(G) rests under the adjustment biock (H).

Figure 3-3: NEUTRAL position; n^ier

(G) rests against middie area of the ad

justment block (H).

Figure 3-4: REVERSE position; roller

(G) rests against upper area of the ad

justment block (H).

If both Forward Interlock Levers are

released before first returning the

Wheels/Tines/PTO Drive Lever to

NEUTRAL, the engine will stop.

IMPORTANT:

The Forward Interlock

Levers are a safety control that stops the

engine should you lose control while

going forward and cannot shift into

NEUTRAL.

Wheel Speed Lever

Use the Wheel Speed Lever (C, Fig. 3-1)

to select one of three operating positions:

SLOW, FAST or FREEWHEEL.

• SLOW - Lever moved all the way down.

Most effective for normal tilling or for

low-speed transport.

• FAST - Lever moved all the way up.

Most effective for cultivating or for fast-

speed transport.

• FREEWHEEL - Lever in between SLOW

and FAST (wheels will roll freely). Used

when transporting the machine on level

ground without engine power, and when

using stationary PTO attachments.

IMPORTANT:

To avoid transmission

damage, always move Wheels/Tines/PTO

Drive Lever into NEUTRAL before shifting

the Wheel Speed Lever.

IMPORTANT:

When shifting into SLOW

or FAST, gently roll the machine forward

or backward to help fully engage the

wheel gears. When engaged, the wheels

will not turn unless the engine is running

and the Wheels/Tines/PTO Drive Lever is

engaged in FORWARD or REVERSE.

Tines/PTO Clutch Lever

Use this lever (D, Figure 3-1) to engage or

disengage power from the transmission

PTO clutch to the tines or any PTO attach

ment. This control has two operating

positions: ENGAGE and DISENGAGE.

• ENGAGE - Lever moved into detent slot

farthest from engine. Use this position to

operate tines or other PTO attachments.

After shifting to ENGAGE, briefly operate

machine in FORWARD to help fully

engage the PTO clutch.

• DISENGAGE - Lever moved into detent

slot nearest engine. Use this position to

disengage power to tines or other PTO

attachments before transporting, loading,

turning, or operating in reverse.

IMPORTANT:

To avoid transmission

damage, always move the Wheels/Tines/

PTO Drive Lever into NEUTRAL before

shifting the Tines/PTO Clutch Lever.

Depth Regulator Lever

Use this lever (E, Figure 3-1) to regulate

the tilling depth of the tines. This control

also has a TRAVEL position, which

enables transport with the tines off the

ground.

To operate the lever, lift up on the handle

bars, pull the Depth Regulator Lever

straight back, and then slide it up or down

to one of the eight detent height settings.

The eight detent positions offer a range of

tine height settings. This enables you to

select the height that is most effective for

a particular condition. The top detent

position is the TRAVEL setting. Use the

second or third detent from the top for

shallow tilling and cultivating. Use the

other detents for deeper tilling and for

power composting.

A

WARNING

To

avoid

personal

injury,

always place the tines in the TRAVEL

position

before

starting

the

engine.

This prevents the tines from touching

the ground until you are ready to begin

tilling.

Handlebar Height Adjustment

Lever

Use this lever (F, Figure 3-1) to adjust the

handlebars to one of two height settings.

1. To change the height, hold the handle

bars with one hand and loosen the lever in

a counterclockwise direction.

2. Move the handlebars to one of the two

preset height settings.

3. RetIghten the lever.

NOTE: You can swap the positions of the

inside handlebar ratchets to change the

two preset settings by approximately four

inches higher or lower. See Section 2,

Step 2: Attach Handlebarior

detailed

assembly information.

14