Auger shear bolts, Caution, Off-season storage – Troy-Bilt 42000 User Manual

Page 27: Off season storage, Sectíoo 5: maintenance (continued)

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Sectíoo 5: Maintenance (continued)

5. Loosen the belt guides on the back of

the auger housing, below the auger

drive pulley. Rotate the guides to

allow removal of the auger drive belt.

Remove the auger drive belt.

INSTALLATION:

1. Position the auger drive belt around

the auger drive pulley in the auger

housing.

2. Adjust and tighten any belt guides

^ loosened during step 5, “REMOVAL.”

Adjust the belt guides 1/16” (Imm)

away from the auger drive belt when

the belt is tight against the auger

drive pulley.

3. Move the auger housing and the

frame/handlebar assembly together

and position the auger drive belt (S,

Fig. 5-9) around the drive pulley on

the engine (T).

4. Secure the auger housing and the

frame/handlebar assembly together

with the

four

flange bolts (X) removed

earlier.

5. Adjust and tighten any belt guides (U)

loosened earlier during step 4,

“REMOVAL”. Adjust the belt guides

1/16” (1mm) away from the auger

drive belt (S) when the belt is tight.

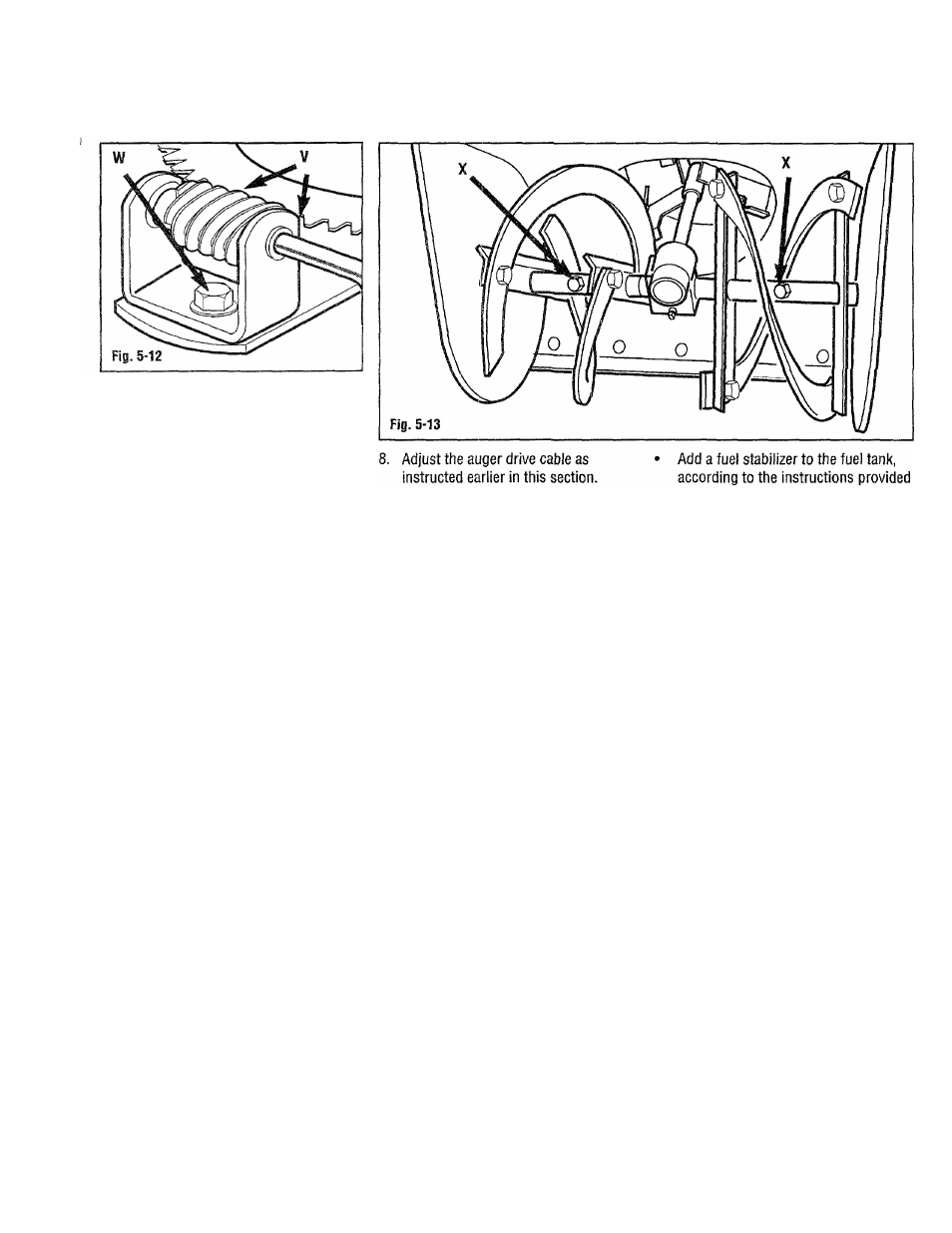

6. Position the worm gear and support

(V. Fig. 5-12) back in place on the

unit. Secure the worm gear and

support with bolt (W).

7. Rotate the chute control crank and

check for binding. Reposition the

worm gear and support (V) as needed

for smooth operation.

9. Position the belt cover (G, Fig. 5-10)

and secure with the two bolts

removed earlier.

Auger shear bolts

The auger shear bolts (X, Fig. 5-13)

are designed to shear if the auger

becomes jammed. This prevents damage

to other parts of the unit. Replace these

shear bolts with only original equipment

replacements (part number 1720515),

and tighten to a torque value of 11 ft. lbs.

(15 Nm).

CAUTION

USING ANYTHING BUT

ORIGINAL EQUIPMENT SHEAR

BOLTS COULD RESULT IN

DAMAGE TO THE UNIT.

Off-season storage

When storing the unit for more than

90 days, follow these procedures to help

keep the unit in good condition for future

use;

•

Clean dirt, grime and grease from the

unit and engine.

•

Perform routine lubrication as

instructed earlier in this section.

with the stabilizer. Avoid leaving non-

stabilized fuel in the fuel tank for

longer than 30 days because gum and

other deposits can form which could

foul the carburetor and fuel line.

If the unit is equipped with a fuel

shut-off valve, rotate the valve to the

“OFF’ position.

Change the engine oil.

Remove the spark plug and squirt 1/2

ounce of engine oil into the spark

plug hole. Hold a rag over the hole

(be careful to prevent the rag from

entering the hole). Slowly pull the

recoil starter several times to coat the

cylinder wall with oil. Re-install the

spark plug, but leave the spark plug

wire disconnected from the spark

plug.

Thoroughly inspect the unit for any

loose, damaged, or missing parts.

Repair or replace the parts as

necessary.

Check all nuts, bolts and other

fasteners for tightness and tighten as

necessary.

Touch-up scratches and chipped paint

to prevent corrosion.

Store the unit on a level surface, out

of the reach of children.

27