Engine air cieaner, Carburetor, Lubrication – Troy-Bilt 42000 User Manual

Page 23: Carburetor lubrication

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section 5: Maintenance (continued)

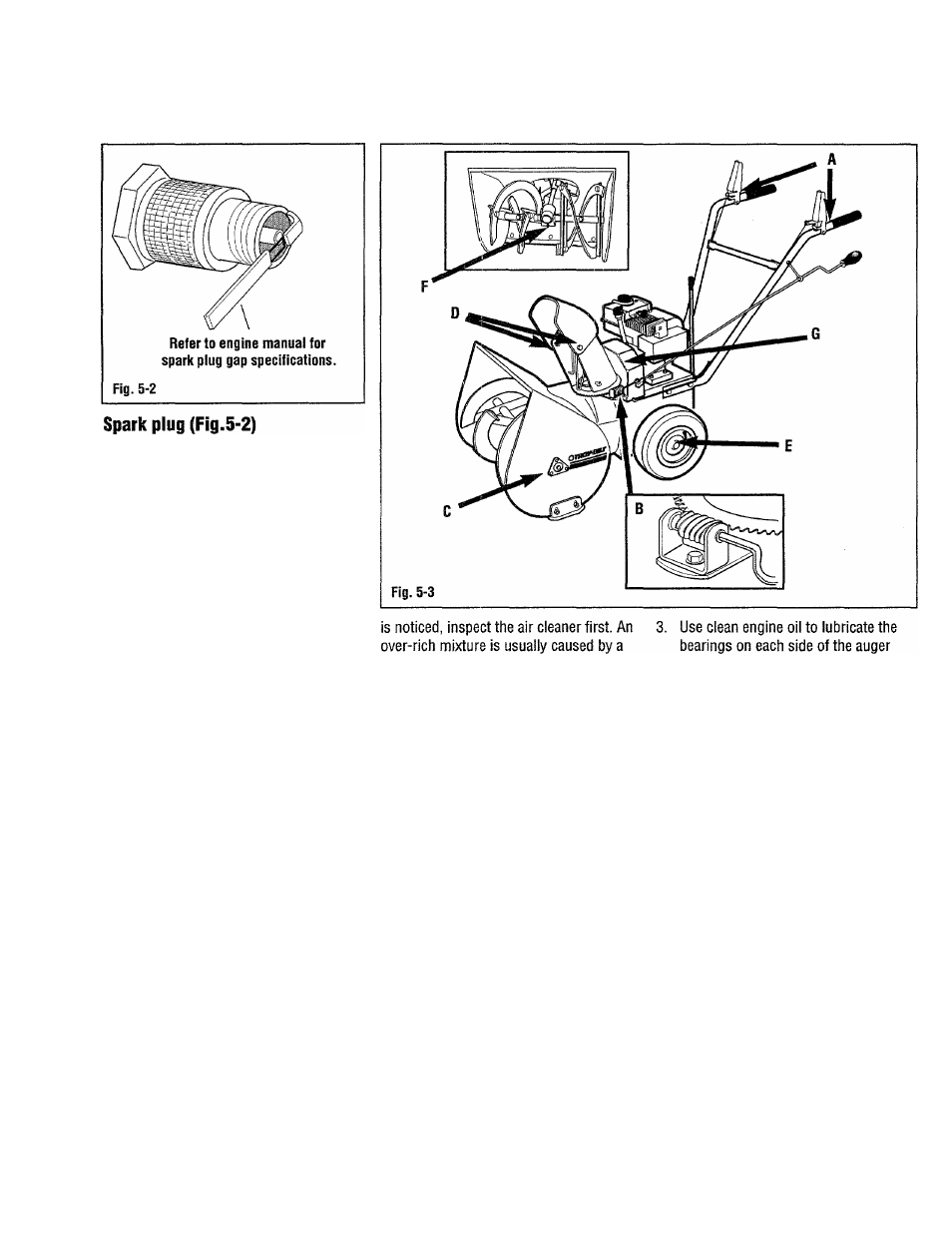

Annually or every 100 hours of

operation, remove and inspect the spark

plug. Reset the gap to the specifications

indicated in the engine owners manual.

Best results are obtained with a new

plug. Replace the plug if it is cracked,

badly worn or otherwise damaged. Refer

to the engine owners manual for correct

spark plug specifications. USING AN

INCORRECT PLUG CAN DAMAGE THE

ENGINE.

Under good operating conditions,

the plug will have a light gray coating or a

tan deposit. A dull white, blistered

coating could indicate an over-rich fuel

mixture caused by a clogged air cleaner

or improper carburetor adjustment.

Note: Do not clean the park plugs In

machines which use abrasive grit.

Clean spark plugs by scraping or wire

brushing or washing with a commercial

solvent.

Engine air cieaner

Refer to the engine owner manual

for engine air cleaner maintenance

instructions.

Carburetor

The carburetor has been adjusted at

the factory and should not require

additional adjustment. If a black exhaust

poorly service or clogged air cleaner

element, not an improperly adjusted

carburetor. Contact your dealer or our

service department for additional

carburetor information.

Lubrication

Lubricate the unit at the beginning

and the end of each season. This will

prepare the unit for peak performance for

the first snowfall and will prevent

corrosion at friction points during the off

season.

1. Use clean engine oil or a silicone

spray to lubricate the control lever

pivot points (A, Fig. 5-3).

2. Clean any dirt off the worm gear and

the toothed part of the flange (B) at

the bottom of the discharge chute.

Apply multi-purpose grease to the

worm gear and the toothed part of the

fiange.

shaft. Wipe off any excess oil.

4. Use clean engine oil or a silicone

spray to lubricate the deflector cap

pivot points (D).

5. Securely block the unit and remove

the wheels. Apply multi-purpose

grease to the axle shaft (for easier

wheel removal).

6. Move the unit to a level area and

inspect the auger gear case oil level

as follows:

a. Remove the drain plug (F) from the

auger gear case: oil should just

begin to flow out of the hole.

b. Inspect the oil for grit and burned

odors. Fill as needed with SAE 90

gear oil.

c Replace and tighten the drain plug

(F) on the auger gear case.

23