Checking and adjusting tension on clutch belts, Warning – Troy-Bilt PONY E666M User Manual

Page 21

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

A

WARNING

» n

Before inspecting, cieaning or servicing the machine, shut off engine, wait tor aii moving parts to

come to a compiete stop, disconnect spark plug wire and move wire away from spark plug.

Remove the key from the keyswitch on units so equipped.

Failure to follow these instructions can result in serious personal injury or property damage.

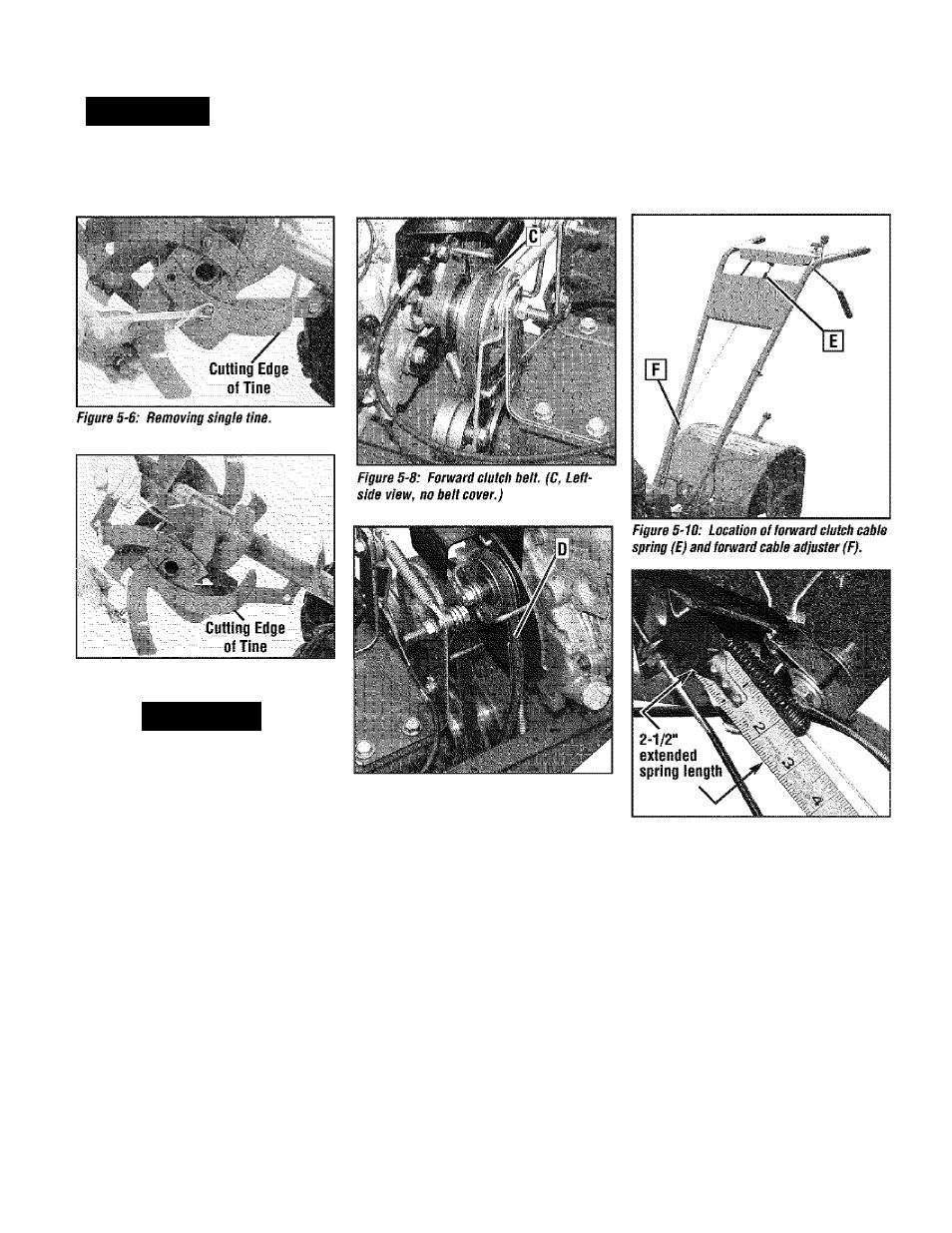

Figure 5-7: Removing a tine assembly.

A

WARNING

Follow the belt adjustment Instructions

carefully. An incorrect adjustment could

result in the clutch control mechanism

engaging too soon. This could cause

loss of tiller control and result in per

sonal injury or property damage.

CHECKING AND ADJUSTING

TENSION ON CLUTCH BELTS

Maintaining correct belt tension is Impor

tant to good tilling performance and long

belt life. A loose belt will slip on the

engine and transmission pulleys and

cause the tines and wheels to slow down

- or stop - even though the engine Is

running at full speed. A loose belt will

also result in premature belt wear.

While checking belt tension, also check

for cracks, cuts or frayed edges. A belt In

poor condition should be replaced.

Tension on a new forward clutch belt (C,

Figure 5-8) should be checked after the

Figure S-9: Reverse eiutch belt (D).

(Right-sirle view, no belt cover.)

first two (2) hours of operation and after

every ten (10) hours of operation.

The reverse clutch belt (D, Figure 5-9),

because it Is used more sparingly, may

not require tension adjustment until a sig

nificant number of operating hours has

passed. A tension adjustment is required

only If there is little or no reverse move

ment when the Reverse Clutch Control

knob is pulled out.

Checking and Adjusting

Forward Ciutch Beit Tension

It is important to maintain correct tension

on the forward clutch belt. A loose belt

will cause the tines and wheels to slow

down -- or stop completely - even though

the engine is running at full speed.

Figure 5-11: Correct spring iengtb when

Forward Clutch Levers are engaged is 2-1/2".

A loose belt will also result in premature

belt wear.

• Check belt tension after the first two

hours of break-in operation and after

every 10 operating hours.

• At the end of each tilling season, check

the belt for cracks, cuts or frayed edges.

A belt in poor condition should be

replaced.