Keep stitching straight, Pin basting, Keeping stitching straight pin hasting – SINGER W6105 User Manual

Page 13

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

blHLHING UPS

Wlienever you start to sew - -

• Check tliat levers and dials are set

correctly tor the stitch you want -

stitch pattern, width, and length.

• Use proper needle and thread for

your

fabric.

Needle

sliould

be

straighi, sharp, and inseried pro

perly. Change your needle frequeni-

ly-

•

Test machine stitch on double

thickness ot a scrap of the fabric

you plan io use. Adjust machine for

length

of

stitch,

tension

and

pressure if necessary.

• Place fabric under presser foot with

bulk of material to the left of

needle. Full thread ends behind

presser foot.

• To prevent liglitweiglit fabrics from

being drawn into needle hole when

you begin stitching, start about 'A''

from edge of fabric.

• To reinforce ends of seams, begin

and end by backstitching about '/

2

"

from edge of fabric.

• Regulate speed of machine by in

creasing or decreasing pressure on

loot control. Run machine at a

slow even speed.

•

Allow tahiic to teed lorward with

the movement of the fabric feed.

Don’t pull 4)r hold labric back as

needle may bend or break. Instead,

guide fabric gently with your liand

in front of presser foot.

• Wlien finished stitching, turn hand

wheel toward you to raise needle to

its highest position betöre removing

labric from under pressci foot, l>u||

threads over thread culler located

at back of presser bar, and press

threads down to cut.

Keep Stitching Straight

Ir> help keep your stitching straight

whether stitching seams or doing

dec-

rat ive stitching:

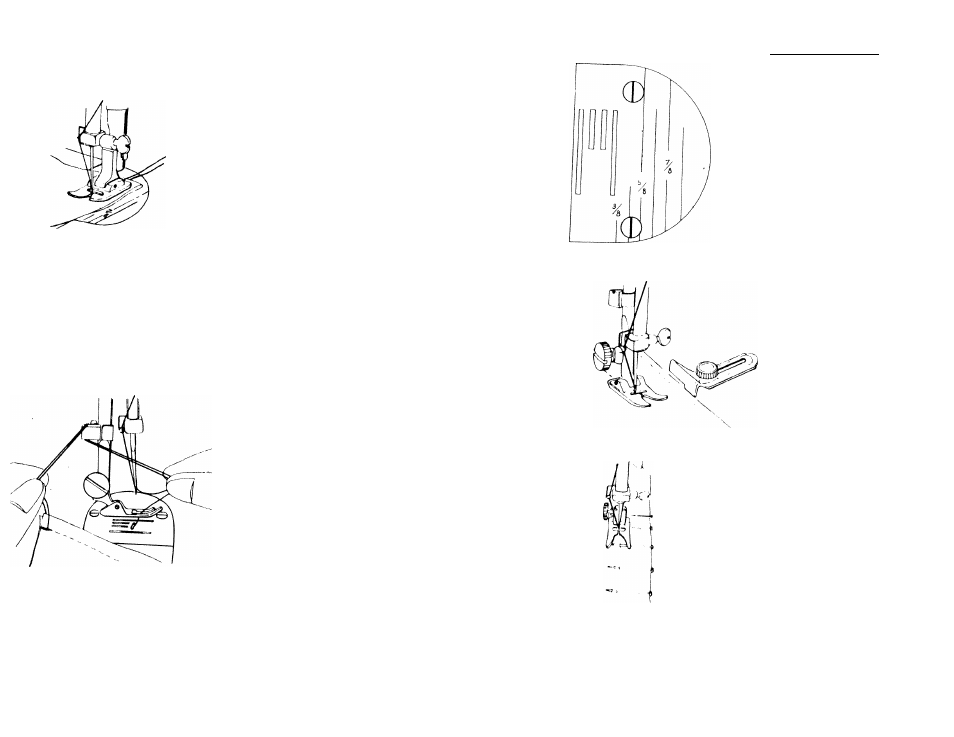

Needle Plate -

Use markings on needle plate as a

guide tor stitching.

Most common measurement is 5/8”

wliicti is used lor stitching seams.

Simply line edge of fabric up wiili

markings on plaie to keep stitching

straight and seam width even.

• Cloth Guide Attachment - -

Use as a guide for stitching seams

hlindstitching, and topstitching

Can be adjusted up to 1-5/8” fron

needle.

hasten cloth guide to machine b>

inserting ihmub screw into one ol

the two threaded holes in bed ol

machine. Adjust cloth guide to

dcMirnl distance from needle and

iigliieii ihiuiih screw.

Pin Basting

I’lace pins at right angles to pres,sei

loot with pin just nipping into fabric

at stitching line. Never place pins on

underside of fabric in contact with

labric teed or so presser foot rides ovei

head of pin.