Adjusting stitches to suit stretch fabrics – SINGER 9618 User Manual

Page 29

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

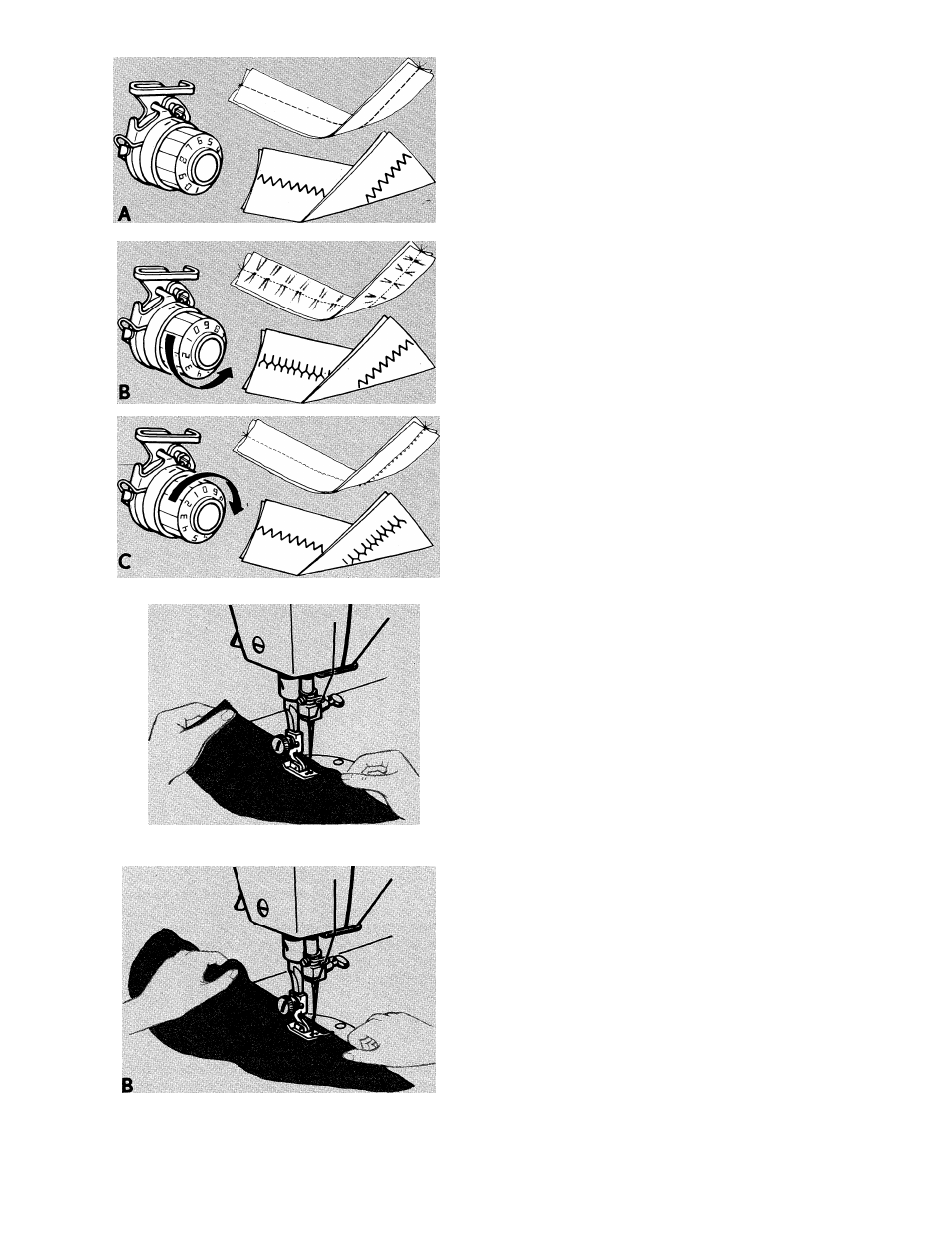

ADJUSTING NEEDLE THREAD TENSION

Correct

tension

is

important

because

too

much or too little will weaken your seams or

cause your fabric to pucker.

Zig-Zag stitching requires less needle thread

tension than straight stitching.

Make a test sample with the fabric and thread

you plan to use so that you can adjust the

tension properly.

A well balanced stitch, as shown In illustration

A, will have the needle and bobbin threads

locked between the two layers of fabric with

no loops on top or bottom and no puckers.

The

tension

dial

regulates

the

degree

of

tension

on

your

needle

thread.

Set

it

according to the type of thread and fabric you

use. The numbers on the dial eliminate guess

work.

If the fabric puckers B, decrease tension. If

the stitches in your test sample look loose C,

increase needle thread tension.

• To decrease tension, turn dial to lower

number.

• To increase tension, turn dial to higher

number.

Adjusting stitches to suit

stretch fabrics

GUIDING AND SUPPORTING FABRIC

Most fabrics of stretch or knit construction

need only to be guided in front of the presser

foot when you use one of the stretch stitches.

Some fabrics - nylon tricot and elasticized

fabrics, for example - do require support while

being stitched.

For nylon tricot and similar synthetic knits,

apply gentle tension by holding the seam in

front and back of the presser foot as you

sew (illustration A).

For elasticized fabric, stretch lace, and knits

with an unusual amount of elasticity, apply

firm tension in front and back of the presser

foot to stretch the seam as the stitches are

being placed (illustration B).

CAUTION: Do not pull the fabric while you are

stitching as this may deflect the needle, causing

it to break.

27