SINGER W1665 User Manual

Page 20

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

18

chalk. Make

to be sure machine

(

1

)

BUTTONHOLES

Buttonholes

of

various

widths

and

lengths

can

be

made

automatically

by

just

turning

the

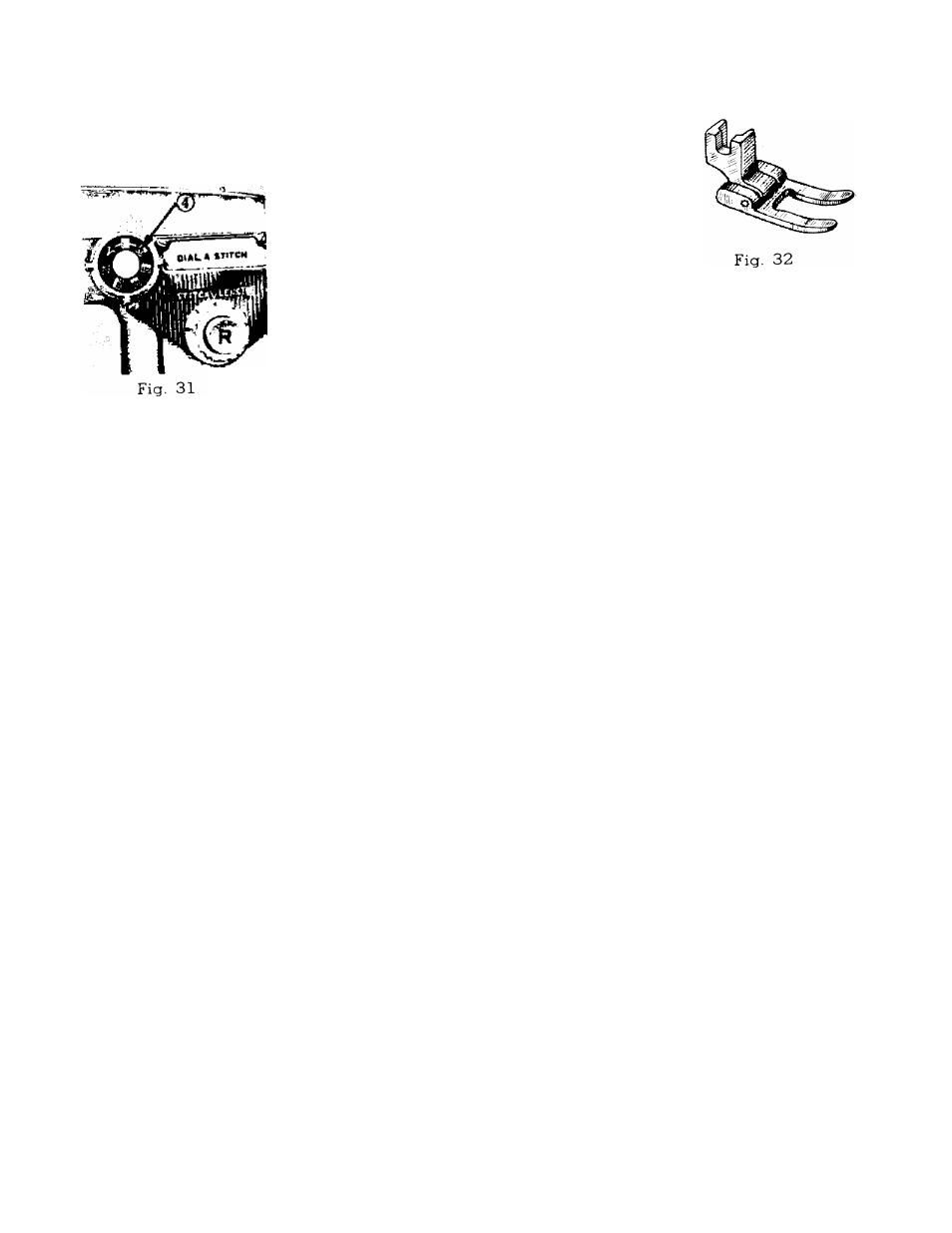

decorative stitch dial 4 (Fig. 31).

To

establish

the

correct

length

buttonhole

reguired, add 1/8 inch to the cutting space for

bar tacks.

To obtain the length of the cutting space,

the opening through which the button passes is

measured

by

adding

the

width

(A)

and

thick

ness (B) of the button. (Fig. 33)

The width of the buttonhole sides are gov

erned by the thickness of the material used.

Set zigzag stitch width lever 14 (Fig- 1)

number 5 for thick material and a lower num

ber for thin material.

Mark the beginning and end of the button

hole

on

fabric

with

a

basting

line

or

tailor's

a

buttonhole

on

scrap

fabric,

following

directions

below

adjustments are correct.

O O

o o

B

U

Fig. 33

(

2

)

(

3

)

feed-

Replace

presser

foot

with

special

purpose

buttonhole

foot,

it

provides

maximum

visibility

and

allows

closely

spaced

stitches to feed evenly. (Fig. 32)

Set stitch length knob 9 (Fig. 1) as near 0 as possible without stopping the

Position zigzag stitch width control lever 14 by left hand lock 13 (Fig. 1) to suit

material being sewn or width of buttonhole desired. (Number 5 for the wides

buttonhole)