Checks and adjustments, Startup, Gas supply pressure – Sears 9MPD User Manual

Page 38: Manifold gas pressure adjustment, Adjust pilot burner, Main burner flame check, Temperature rise check, Checks and adjustments startup, Caution

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Figuro 40

Condensate Line Raised by Base

8. Checks and Adjustments

Startup

NOTE: Refer to the start-up procedures in the

"User's Informa

tion Manual'

or to the

"Operating Instructions Label'

on the fur

nace.

CAUTION

If any sparks, odors or unusual noises occur, immediately

shut

OFF

power

to

furnace.

Check

for

wiring

errors

or

obstruction to blower.

Gas Supply Pressure

Gas supply pressure should be within minimum and maximum

values listed on rating plate. Pressures are usually set by gas sup

pliers.

Manifold Gas Pressure Adjustment

NOTE: Make adjustment to manifold pressure with burners oper

ating.

FIRE OR EXPLOSION HAZARD

Failure to turn OFF gas at shut off before connecting

manometer can result in death, personal injury and/or

property damage.

Turn OFF gas at shut off before connecting manometer.

1. Remove the burner compartment door.

2. With gas

OFF,

connect manometer to tapped opening on

gas valve. Use manometer with a 0 to 15" water column

range.

3. Turn gas

ON

and remove adjustment screw cover on gas

valve. Turn counterclockwise to decrease pressure and

clockwise to increase.

4.

For altitudes up to 2000', set pressure to value shown in

Table 6,

+ 0.3" {

8

mm) water column. For altitudes of 2000'

to 8000', see Section 5 for correct pressure setting.

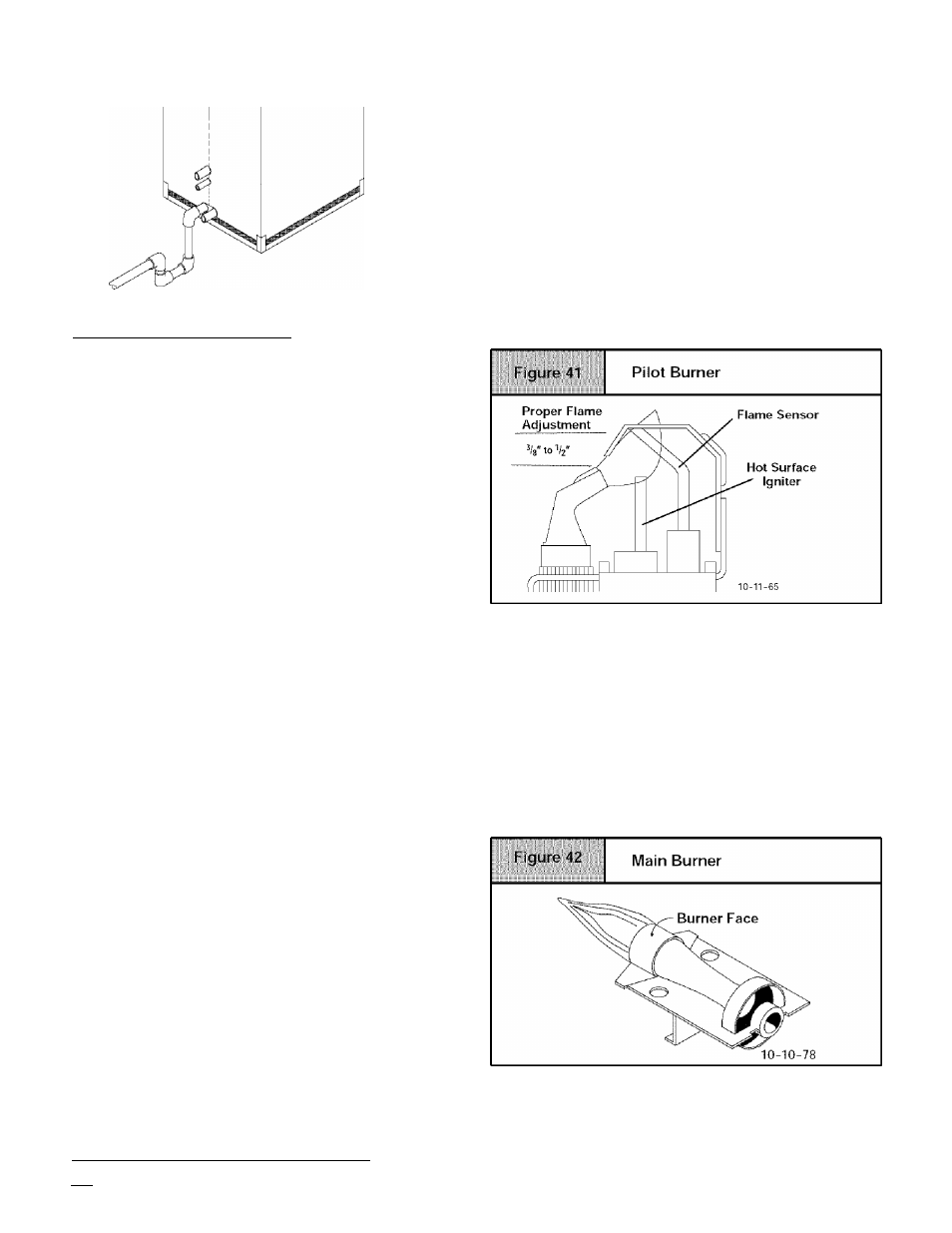

Adjust Pilot Burner

The furnace has a pilot flame to light the main burner. The flame

should surround ^/g" to V

2

" of the flame sensor. See

Figure 41

. To

adjust, remove cap from pilot adjusting screw on gas valve. Turn

screw counterclockwise to increase or clockwise to decrease

flame as required. Replace adjusting screw cap.____________

Main Burner Flame Check

Allow the furnace to run approximately 10 minutes then inspect

the main burner and pilot flames. See

Figure

42.

Check for the following

(Figure 42):

• Stable and blue flames. Dust may cause orange tips or

wisps of yellow, but flames

MUST NOT

have solid, yel

low tips.

• Flames extending directly from burner into heat ex

changer.

• Flames do

NOT

touch sides of heaf exchanger.

If any problems with main burner flames are noted, it may be nec

essary to adjust gas pressures, or check for drafts.

Temperature Rise Check

The blower speed

MUST

be set to give the correct air temperature

rise through the furnace as marked on the rating plate. Tempera

ture rise is the difference between supply and return air tempera

tures.

Ì38l

44001

1114

00