Gas supply and piping, Alternate btuh input ratings (usa only), Supply pressure – Sears 9MPD User Manual

Page 30: Gas supply pressure, Manifold gas pressure adjustment

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

5. Gas Supply and Piping

CARBON

MONOXIDE

POISONING,

FIRE

AND

EXPLO

SION HAZARD

Models

designated

for

Natural

Gas

are

to

be

used

with

Natural

Gas

Only,

unless

properly

converted

to use with LP gas.

Furnace operating with the wrong fuel result in death,

personal injury and/or property damage.

NOTE: The rating plate is stamped with the model number, gas

type and gas input rating. In addition, models manufactured for

sale in Canada have orifice size information stamped on the rat

ing plate.

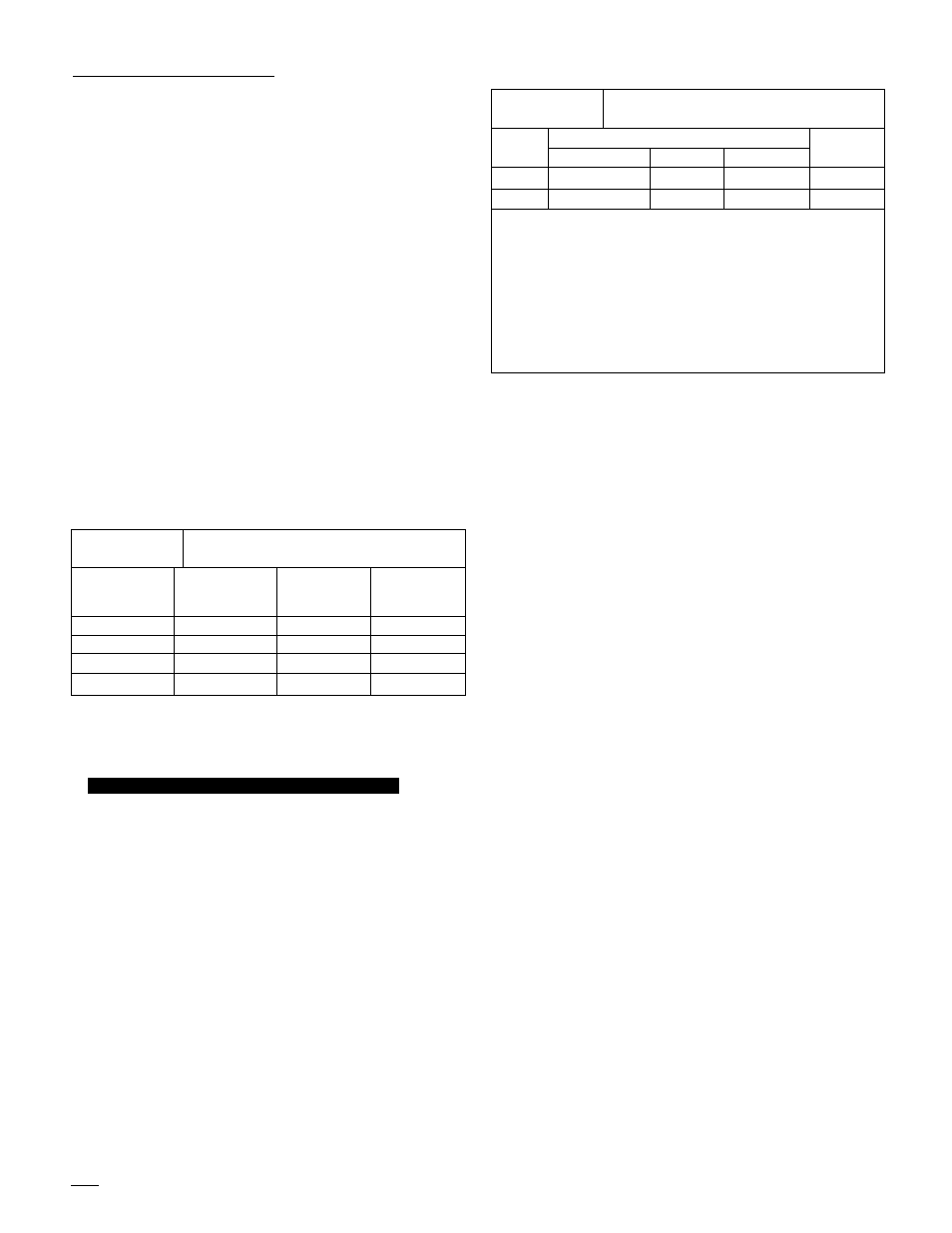

Alternate BTUH Input Ratings (USA Only)

The input rating of these furnaces can be changed from the stan

dard input rating to the alternate input rating shown in

Table 5,

by

changing the main burner orifices. NOTE: The input rating ot

80,000 BTUH models cannot be changed from the standard in

put. Changing of burner orifices MUST be done by a qualified ser

vice technician. See section on changing orifices or following

page.

Table .5

Alternate Input Ratings, USA ONLY.

BTUH

Standard

Rating

BTUH

Alternate

Rating

Natural

Gas

Orifice

LP

Gas

Orifice

50,000

40,000

#44

#55

75,000

60,000

#44

#55

100,000

80,000

#44

#55

125,000

100,000

#44

#55

Supply Pressure

FIRE HAZARD

Failure

to

properly

set

input

pressure

can

result

in

death, personal injury and/or property damage.

Do NOT set input rating above that shown on rating

plate.

1. Supply pressure can be checked using the Vg" NPT port

on the supply side of the gas valve.

2.

Gas input to burners

MUST NOT

exceed the rated input

shown on rating plate.

3. Do

NOT

allowminimumgassupply pressure to vary down

ward. Doing so will decrease Input to furnace. Refer to

Table 6

for normal gas supply and manifold pressures.

Table 6

Gas Pressures Below 2000'

Gas

Type

Supply Pressure

Manifold

Pressure

Recommended

Max.

Min.

Natural

7"

14”

4.5"

3.5"

LP

11”

14”

11”

10"

Important Note:

•

With Propane gas, the rated input is obtained when the

BTU content is 2,500 BTU per cubic foot and manifold

pressure set at 10" W.C.

•

If Propane gas has a different BTU content, orifices

MUST be changed by licensed Propane installer.

• Measured input can NOT exceed rated input.

•

Any major change in gas flow requires changing burn

er orifice size.

Gas Supply Pressure

Gas supply pressure should be within minimum and maximum

values listed on rating plate. Pressures are usually set by gas sup

pliers.

Manifold Gas Pressure Adjustment

NOTE: Make adjustment to manifold pressure with burners oper

ating.

FIRE OR EXPLOSION HAZARD

Failure to turn OFF gas at shut off before connecting

manometer can result in death, personal injury and/or

property damage.

Turn OFF gas at shut off before connecting manometer.

1. Remove the burner compartment door.

2.

With gas

OFF,

connect manometer to tapped opening on

gas valve. Use manometer with a 0 to 15" water column

range.

3. Turn gas

ON

and remove adjustment screw cover on gas

valve. Turn counterclockwise to decrease pressure and

clockwise to increase.

4.

For altitudes up to 2000', set pressure to value shown In

Table 6,

± 0.3' water column.

5.

Connect manometer to the tapped opening on the outlet

side of gas valve. Use manometer with a 0-15 ' min. water

column range.

6

.

Turn gas

ON,

fire the furnace and remove adjustment

screw cover on gas valve.

7.

Turn counterclockwise to decrease pressure and clock

wise to increase.

8

.

SetpressuretovalueshowninTable

6.

Refer to

Important

Notes

in Table

6.

Pressure is also listed on furnace rating

plate.

9. When pressure is set, replace adjustment screw cover on

gas valve.

10. Replace the burner compartment door.

О3Ф1

44001

1114

00