Woodworking, Wiring diagram, Recommended accessories – Sears 113.23611 User Manual

Page 17: Trouble shooting glossary of terms for

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

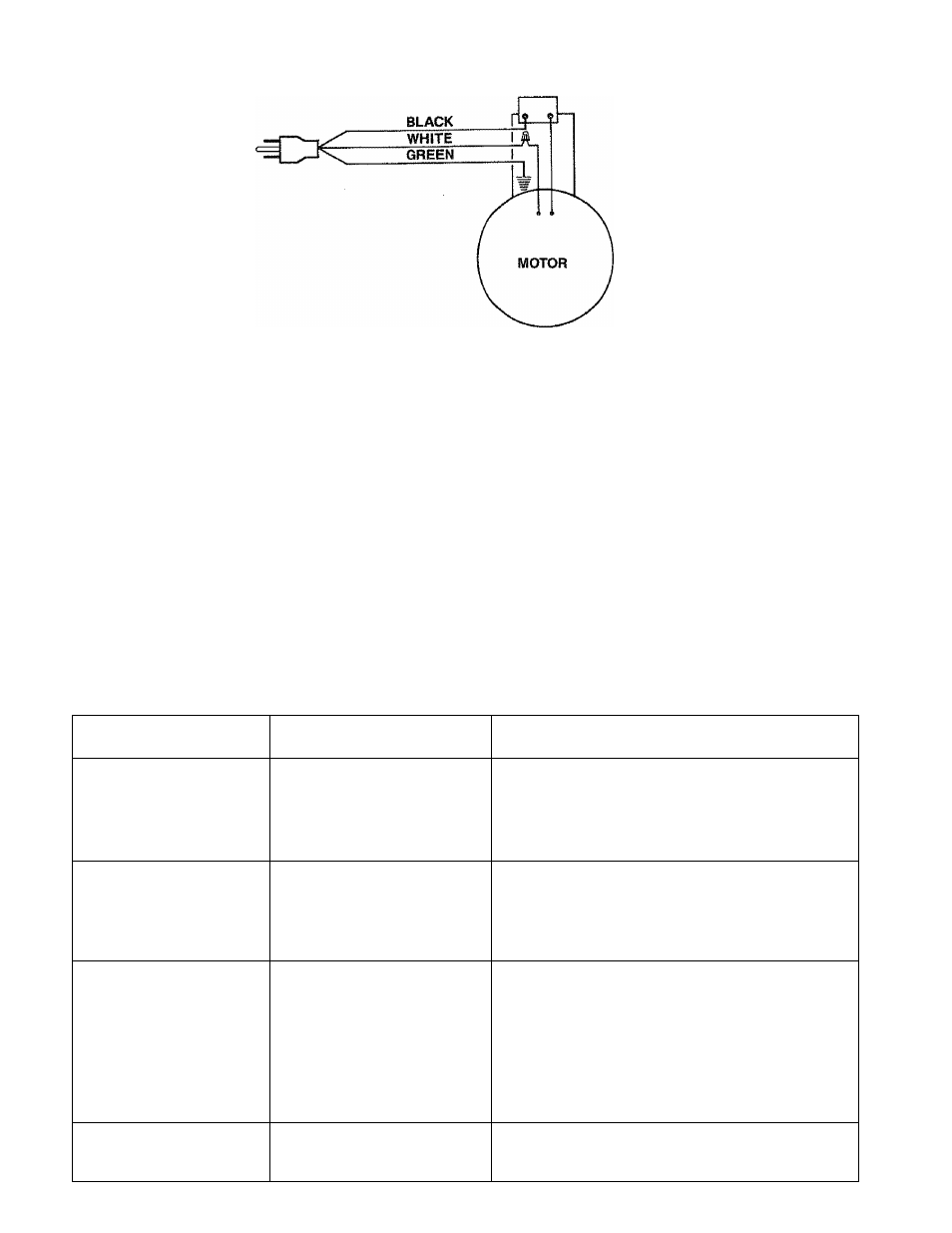

wiring diagram

SWITCH

recommended accessories

Item

Leg Set

Blades

Sears Number

9-22244

See Catalog—For 5" long,

pin end type blades

9-26873—medium radius cuts in wood up to

Vh”

thick

9-26879—fine radius cuts in wood up to V

4

" thick

The above recommended accessories are current and were

avaitable at the time this manual was printed.

trouble shooting

glossary of terms

for

woodworking

1.

Kerf—

the slot cut by the blade

2.

Leading Edge—the edge of the work piece which is

pushed into the blade first.

3.

Sawbtade Path—The area of the workpiece directly

in line with and moving toward the sawblade edge.

4.

Blade Tooth Sef—the distance that the edge of the

sawbtade tooth is bent {on set) outward from the side

of the blade.

5. Trailing Edge—the

workpiece edge last cut by the

sawblade.

6. Work Piece—

the item on which the cutting operation

is beina preformed.

_______

WARNING: FOR YOUR OWN SAFETY, TURN SWITCH “OFF”,

REMOVE KEY AND REMOVE PLUG FROM POWER SOURCE

PROBLEM

PROBABLE CAUSE

REMEDY SUGGESTED

Breaking Blades.

1. Wrong tension.

2. Over working blade.

3. Wrong blade application.

4. Twisting blade in wood.

1

. Mjust blade tension.

2. Reduce feed rate.

3. Use narrow blades for cutting thin wood, wide

blades for thicker wood.

4. Avoid side pressure on blade.

Motor will not run.

1. Defective cord or plug.

2. Defective motor.

1

, Replace defective parts before using saw again.

2. Consult Sears Service. Any attempt to repair this

motor may create a HAZARD unless repair is done

by a qualified service technician. Repair service is

available at your nearest Sears Store.

Vibration

NOTE; There wilt always

be some vibration present

when the saw is running

because of the motor

operation.

1. Improper mounting of saw.

2. Unsuitable mounting

surface.

3. Loose table or table

resting against motor.

4. Loose motor mounting

1. See mounting instructions in this manual for proper

mounting technique.

2. The heavier your work bench is the leæ vibration

will occur. A plywood workbench wilt not be as good

a work surface as the same size solid lumber. Use

common sense in choosing a mounting surface.

3. Tighten table lock knob.

4. Tighten motor mounting screws.

Blade Runout—Blade not

in-line with arm motion

Blade holders not aligned

1. Loosen cap screws holding blade holders to arms.

Adjust position of blade holders—Retighten holders.

17