Sears 113.24611 User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

additional safety instructions for drill presses

11. Note and Follow the Safety Rules that Appear on the

Panel on the Left Side of the Head:

DANGER:

FOR

YOUR

OWN

SAFETY:

READ

AND

LMDERSTAND

OWNERS

MANUAL

BEFORE

OPERATING

THIS

MACHINE.

WEAR

SAFETY

GOGGLES.

DO

NOT

WEAR

GLOVES.

SECURELY

CLAMP WORK TO TABLE IF IT IS TOO SHORT TO

CONTACT

THE

COLUMN

WHEN

IN

OPERATING

POSITION.

12.

Think

Safety. Safety is a combination of operator

common sense and alertness at all times when the drill

press is being used.

WARNING:

DO NOT ALLOW FAMILIARITY

(GAINED

FROM

FREQUENT

USE

OF

YOUR

DRILL

PRESS)

TO

BECOME

COMMONPLACE.

ALWAYS

REMEMBER

THAT

A

CARELESS

FRACTION

OF

A

SECOND

IS

SUFFICIENT

TO

INFLICT

SEVERE

INJURY.

unpacking and checking

Page

General Safety Instructions for Power Tools ......................... 2

Additional Safety Instructions for Drill Presses ...................... 3

Unpacking and Checking Contents ........................................4

Table of Loose Parts .............................................................. 4

Motor Specifications and Electrical Requirements ................ 5

Assembly .............................................................................

Installing the Chuck .........................................................

6

Installing Feed Handles......................................................7

Installing the Depth Stop ................................................

8

Installing Motor Pulley .....................................................

9

Mounting the Motor ......................................................... 10

Installing and Tensioning Belt......................................... 12

Getting to Know Your Drill Press......................................... 12

Belt Tension Rod ............................................................ 12

Drilling Speed.................................................................. 12

On-Off Switch .................................................................. 13

Removing the Chuck ...................................................

14

Drilling to Depth .............................................................. 15

Basic Drill Press Operation ................................................. 15

Installing Drills ................................................................. 16

Positioning Table and Workpiece ................................... 16

Feeding.........................................................................

17

Adjustments ........................................................................ 17

Depth Scale .................................................................... 17

Quill Return Spring ......................................................... 17

Table and Head Lock Handles ....................................... 17

Quill Bearing.................................................................... 17

Pinion Backlash .............................................................. 18

Automatic Feed Return ................................................... 18

Maintenance ........................................................................ 18

Lubrication........................................................................... 18

Recommended Accessories ............................................... 19

Trouble Shooting ................................................................. 19

Repair Parts ......................................................................... 20

UNPACKING AND CHECKING CONTENTS

Your Craftsman Drill Press is shipped complete in one

carton, less motor.

Separate all parts from packing materials and check each

one with the "Table of Loose Parts” to make certain all

items are accounted for, before discarding any packing

material.

If any parts are missing, do not attempt to assemble the

drill press, plug in the power cord or turn the switch on

until the missing parts are obtained and installed correctly.

Remove the protective oil that is applied to the table and

column. Use any ordinary household type grease and spot

remover.

CAUTION: Never use gasoline, naptha or similar highly

volatile solvents.

Apply a coat of automobile wax to the table.

Wipe all parts thoroughly with a clean dry cloth.

4

contents

TOOLS NEEDED

7/16 Inch Wrench

-cO—>

1/2 Inch Wrench

18

Key

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

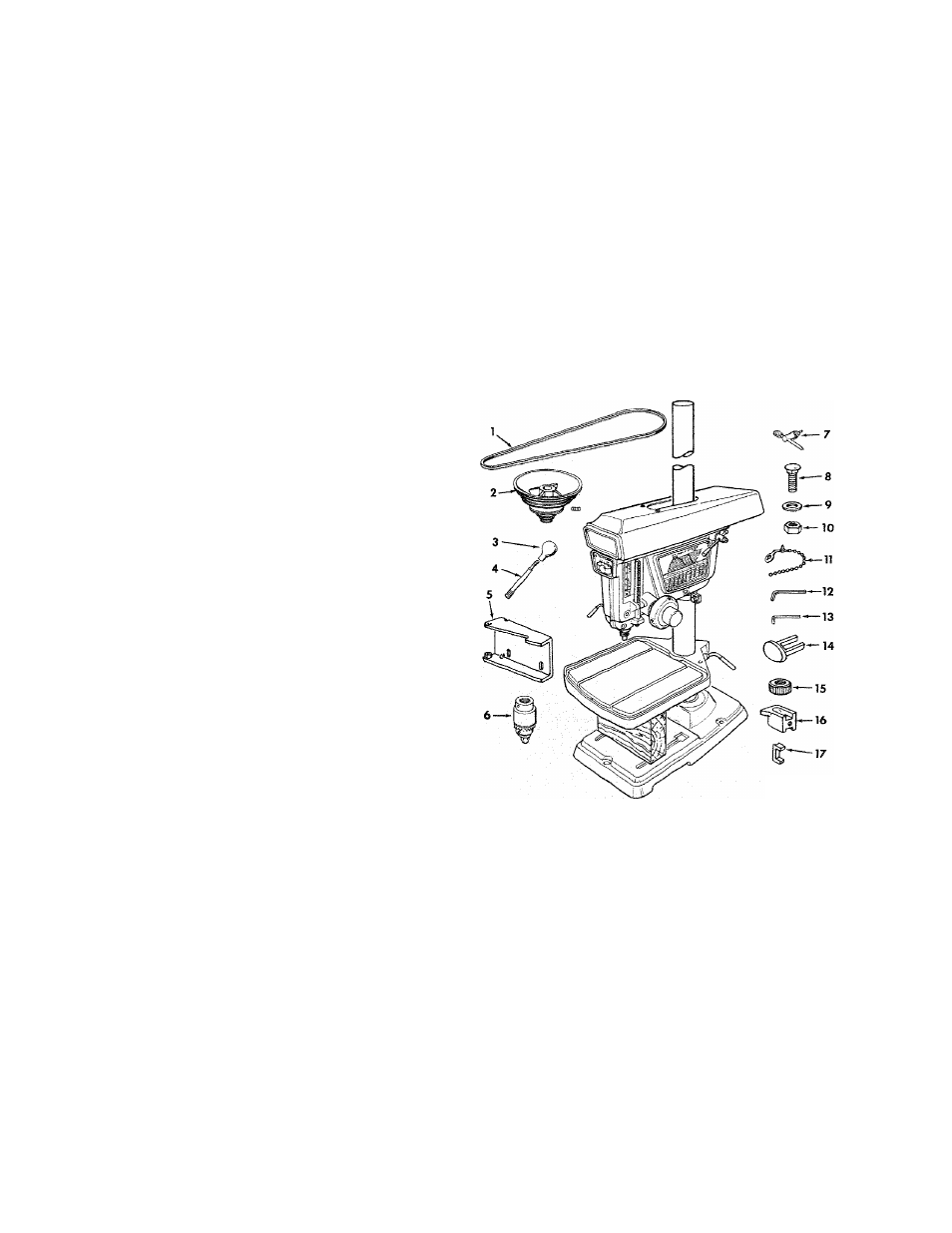

TABLE OF LOOSE PARTS

Item

Qty.

Belt, V ................................................................................ 1

Pulley, Motor (w/Set Screw) .......................................... 1

Knob ....................................................................... 3

Rod ..................................................................................... 3

Mount, Motor ..................................................................... 1

Chuck, Drill . ................................................................... 1

Bag of Miscellaneous Small Parts, Pt. #71177

Consisting of the Following;

Key, Drill Chuck ................................................................ 1

Carriage Bolt (5/16-18 x 3/4) ............................................. 4

Washer (11/32) ................................................................... 4

Nut, Hex (5/16-18) .............................................................. 6

Tie, Wire ........................................................................... 1

Set Screw Wrench (5/32 inch) ......................................... 1

Set Screw Wrench (1/4 inch) ........................................... 1

Key, Switch ...................................................................... 2

Nut, Stop .......................................................................... 1

Pointer, Depth Gage.......................................................... 1

Shoe, Depth Gage ............................................................. 1

Screw, Thumb ................................................................... 1