Adiüsfmerifs – Sears 113.24611 User Manual

Page 17

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

adiüsfmerifs

WARNilMG: FOR YOUR OWN SAFETY TURN SWITCH

"OFF" AND REMOVE PLUG FROM POWER SOURCE

OUTLET BEFORE MAKING ANY ADJUSTMENTS.

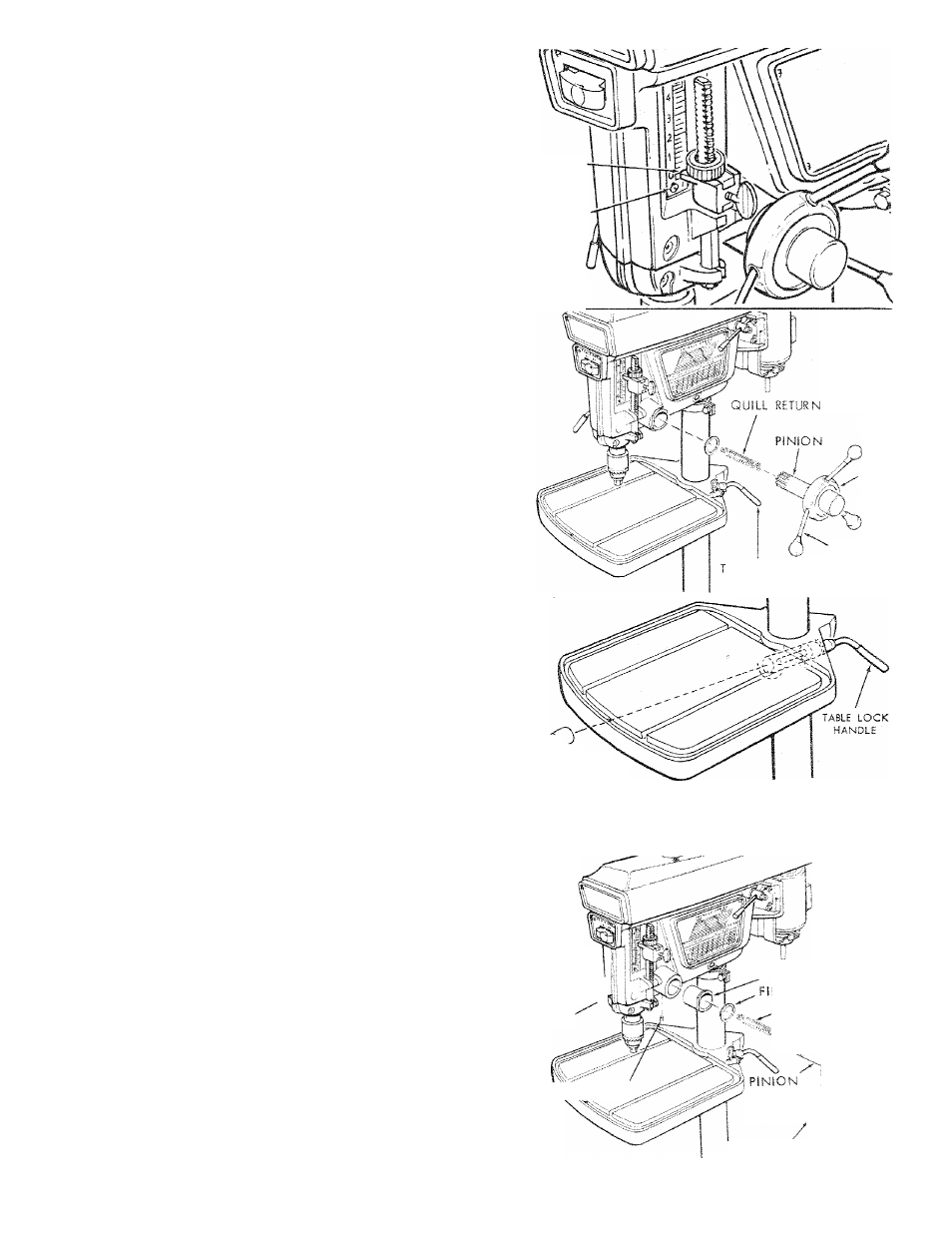

DEPTH SCALE

When the quill is in the UPPERMOST position, the top

SURFACE OF THE FEED STOP POINTER should be in

line with "0" graduation on the DEPTH SCALE.

If it is not . . . LOOSEN both mounting screws and

reposition the scale.

FEED STOP

POINTER

MOUNTING

SCREWS

QUILL

RETURN SPRING

If the quill does not return to its UPPERMOST position

when the quill lock is UNLOCKED . . . or if the return

action is SLUGGISH ... the SPRING TENSION must be

increased.

1

. Move DEPTH POINTER to uppermost position and

lock it in place.

2. Lock the quill in the uppermost position.

3. GRASP the HUB . . . pull it straight out until it is free

to turn.

4. Rotate hub TOWARD you about 1/4 turn and PUSH it

back in place. This will WIND UP the spring.

5. Unlock quill . . . check tension . . . if more is required,

repeat steps 2, 3, 4, and 5.

TABLE AND HEAD LOCK HANDLES

The lock

handles

can be

adjusted to make them more

convenient

to operate.

1. Make sure the support collar is locked in position below

the table or the head.

2

. Unscrew the lock handle and push the barrel lock out

of the hole.

3. Rotate the barrel lock 180°, replace it in the hole and

screw in the handle.

NOTE:

The HEADLOCK HANDLE is located on the LEFT

side of the head.

SPRING

HUB

ABLE LOCK

HANDLE

FEED

HANDLE

IT,

\

BARREL LOCK

BELT TENSION

Refer to section "Getting To Know Your Drill Press"

BELT TENSIONING ROD.

QUILL

BEARING ADJUSTMENT

The front of the head is "Split" which permits an

adjustment to be made as the quill and the quill bearing

surfaces inside of the head become worn after an extended

period of use. The front of the head can be SQUEEZED

together or SPREAD apart by adjusting three screws.

1. TIGHTEN quill lock handle.

2.

LOOSEN setscrew "A" using a 5/32 in. setscrew

wrench.

3.

Rotating the eccentric BUSHING "B" in either

direction will move the pinion shaft TOWARD or

AWAY from the quill.

With a large pair of pliers, rotate bushing so that pinion

shaft moves AWAY from quill.

4. LOOSEN quill lock handle.

QUILL

LOCK

HANDLE

ECCENTRIC BUSHING

3ER WASHER

SPLIT

SET SCREW "A"

FEED RETURN

SPRING '

'

,'/■—'\ VT-/

SHAFT

U.

i'y /'s

H U 8

ASSERABt'-

I FEED HAMUlX

17