Trouble shooting, Trouble shooting -- motor – Sears 113.243311 User Manual

Page 22

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

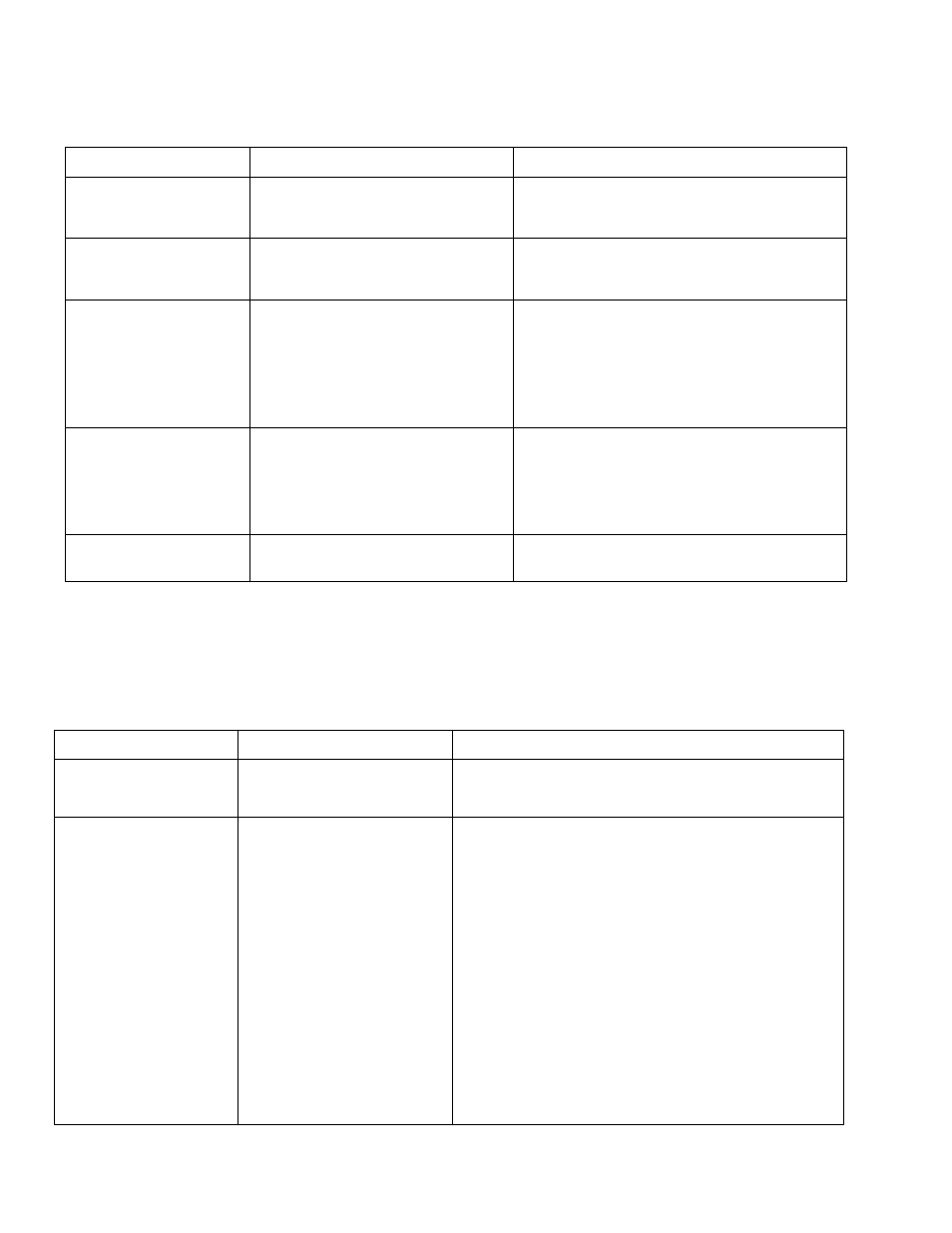

trouble shooting

WARNING: FOR YOUR OWN SAFETY, TURN SWITCH "OFF" AND REMOVE PLUG FROM POWER

SOURCE OUTLET BEFORE TROUBLE SHOOTING YOUR BAND SAW/SANDER.

TROUBLE

PROBABLE CAUSE

REMEDY

Blade does not run in the

approximate center of the

upper wheel.

1. Not tracking properly.

1. Adjust tracking, see Assembly Section.

"Installing the Blade."

.....

Blade does not run in the

1. Lower wheel not positioned

1. Reposition the wheel, see Assembly

approximate center of the

tower wheel.

correctly on shaft.

Section, "Installing the Blade."

Band Saw slows down when

cutting.

1. Belt too loose.

2. Motor pivots in motor base.

3. Cutting too small a radius.

4. Dull blade.

1. Adjust belt tension, see Assembly Section,

"Attaching Belt Guards."

2. Tighten motor base clamp screws. See

Assembly Section, "Motor Installation".

3. Stop feeding, and back up the material

slightly, until the band saw speeds up.

4. Replace blade.

Blades breaking.

1. Too much tension.

2. Kink in blade caused by cutting

too small a radius or turning the

material too fast when cutting.

1. Adjust tension. See Getting To Know

Your Band Saw/Sander, "3 Tension

Scales."

2, Use correct cutting technique. See Basic

Band Saw/Sander Operation Section.

Blade dulls too quickly.

1. Blade guides set too close

to teeth.

1. Adjust upper and lower blade guides. See

Assembly Section "Installing the Blade."

TROUBLE SHOOTING -- MOTOR

NOTE; Motors used on wood-working tools are particularly susceptible to the accumulation

of sawdust and wood chips and should be blown out or “vacuumed” frequently to prevent

interference with normal motor ventilation and proper operation of the centritugatly-

operated starting switch.

TROUBLE

PROBABLE CAUSE

REMEDY

Exces^ve ntrise.

1. Motor.

1. Have motor checked by qualified service

technician. Repair service is available at

your nearest Sears store.

Motor falls to develop

full power. NOTE:

LOW VOLTAGE: (Power

output of motor

1. Circuit overloaded with

lights, appliances and

other motors.

1. Do not use other appliances or motors on

same circuit when using the saw.

decreases rapidly with

decrease in voltage at

motor terminals. For

2. Undersize wires or circuit

too long.

2. Increase wire sizes, or reduce length of wiring.

See “Motor Specifications and Electrical

Requirements” section.

example, a reduction of

10% in voltage causes

a reduction of 19% in

maximum power output

of which the motor is

capable, and a reduction

of 20% in voltage causes

a reduction of 36% in

maximum power output)

3. General overloading of

power company

facilities.

3. Request a voltage check from the power

company.

22