Carrier 58DR User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

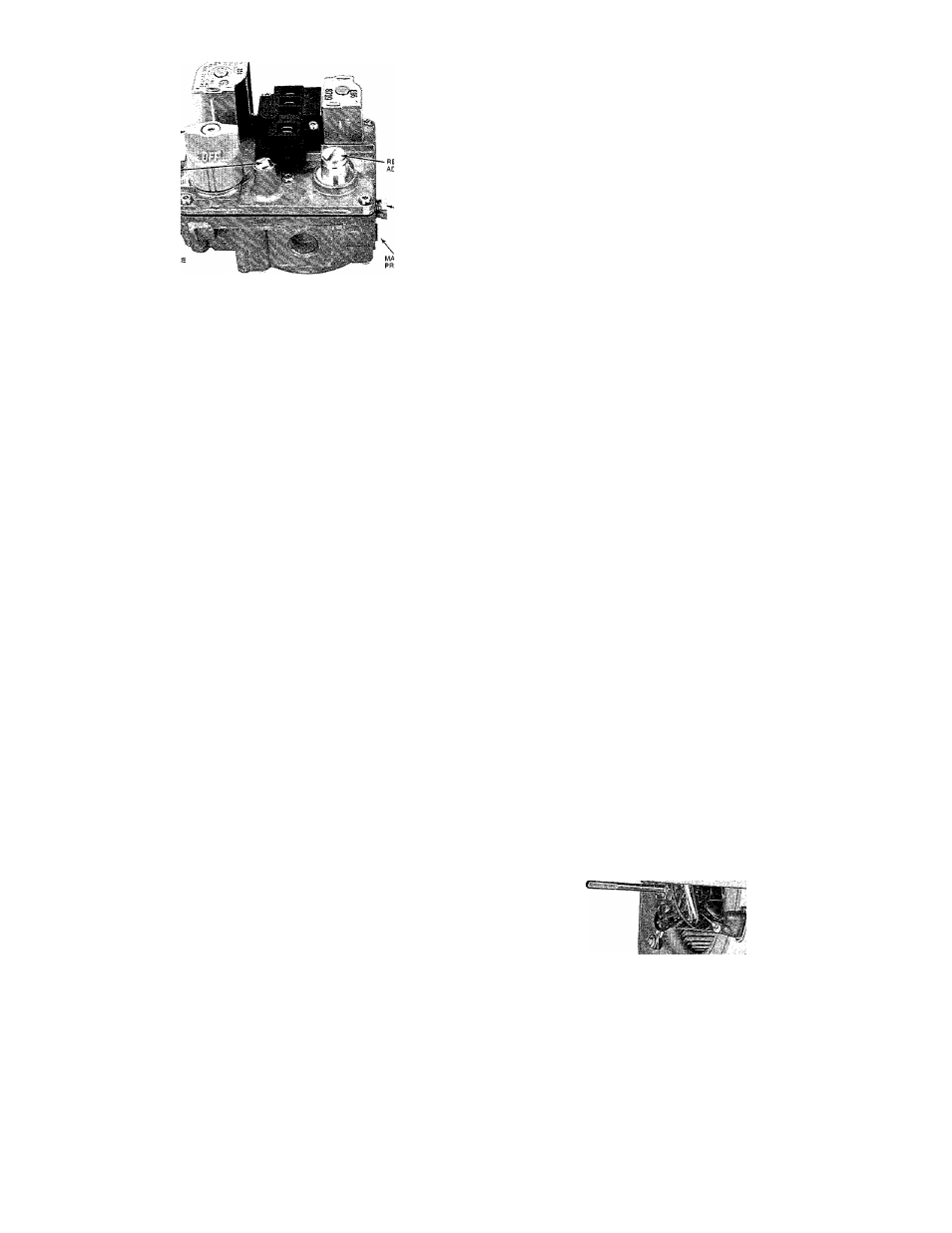

PILOT

ADJUSTMENT-

IN LE'

PRES

TAP

OUTLET

PRESSURE TAP

A87230

Fig. 14—White Rodgers Model 36E

A. Air Filter

Each furnace accommodates two filters which can be

installed above the furnace in the return-air plenum. See

Fig. 11.

To clean or replace the filters, proceed as follows:

1. Disconnect electrical power before removing access

panel.

2. Remove upper access door.

3. Reach up behind top plate, tilt filters toward center of

return-8ur plenum, remove filters, and replace or clean

as needed.

4. Some furnaces are equipped with permanent, washable

filters. Clean those filters as follows:

a. Clean with tap water.

b. Rinse and let dry. No oihng or coating of filters is

required.

c. Reinstall filters with cross-hatch binding facing

blower.

B. Blower Motor Wheel

For long life, economy, and high efficiency; clean accumu

lated dirt and grease from blower wheel and motor annually.

Lubricate motor every 5 years if motor is used on intermit

tent operation (thermostat FAN switch in AUTO position),

or every 2 years if motor is in continuous operation (thermo

stat FAN switch m ON position).

Clean and lubricate as follows:

1. Remove upper access door.

2. Loosen screw in vent pipe enclosure front and remove

vent enclosure front by sliding forward (toward front of

unit).

3. Disconnect vent pipe at first joint above unit and

swing vent pipe assembly to side, supported by suit

able means (block of wood, etc.).

4. Slide vent pipe upward through rectangular opening in

top plate and remove vent pipe from furnace.

5. Remove four screws in vent pipe enclosure back, and

remove enclosure back by tilting top toweurd blower

and sliding bottom toward front of furnace.

6. Disconnect electrical leads from right side of motor

speed selector. Note location of wires for reassembly.

7. Remove screws holding blower assembly against

blower deck and shde blower assembly out of furnace.

8. Squeeze side tabs of motor speed selector and puU it

from blower housing.

9. Units with motor capacitor, loosen screw in strap hold

ing capacitor to blower housing and shde capacitor

from under strap.

10. Mark blower wheel, motor, and motor support in rela

tion to blower housing before disassembly, to insure

proper reassembly.

11. Loosen setscrew holding blower wheel onto motor

shaft.

12. Remove bolts holding motor mount to blower housing

and shde motor and mount out of housing. Some

motors have a ground wire attached to blower housing;

disconnect it also.

13. Lubricate motor (when oilers are provided).

a. Remove dust caps or plugs from oil ports located at

each end of motor.

b. Use good grade of SAE 20 nondetergent motor oil

and put one teaspoon, 5cc, 3/16 oz., or 16 to 25

drops in each oU port.

c. AUow time for total quantity of oil to be absorbed

by each bearing.

d. After oihng motor, be sure to wipe excess oil from

motor housing.

e. Replace dust caps or plugs on oil ports.

14. Remove blower wheel from housing.

a. Mark blower wheel orientation and cutoff location

to insure proper reassembly.

b. Remove screws holding cutoff plate and remove cut

off plate from housing.

c. Lift blower wheel from housing through opening.

15. Clean blower wheel and motor by using vacuum with

soft brush attachment. Care must be exercised not to

disturb balance weights (chps) on blower wheel vanes.

Also do not drop or bend wheel, as balance wih be

affected.

16. Reassemble blower by reversing procedures 14a thru

14c. Be sure wheel is positioned for proper rotation.

17. Reassemble motor and blower by reversing procedures

8 thru 12. If motor has ground wire, be sure it is con

nected as before. Be sure the blower wheel setscrew is

on the flat of the motor shaft when tightening the

setscrew.

18. Reinstall blower assembly in furnace.

19. Reinstall vent enclosure back.

1

A

Fig. 15—Dual Blower With Left-Hand

Housing and Wheei Removed

20. Reinstall vent pipe through opening in top plate, secure

to drafthood and connect remainder of vent pipe

assembly.

21. Reinstall vent enclosure front, and secure with screw.

• 22. Connect electrical leads to Molex speed selector. Please

note that connections are polarized for assembly—

do

not force.

23. Reinstall access door.

9