A warning, Table 6—trouble analysis chart – Carrier 58DR User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

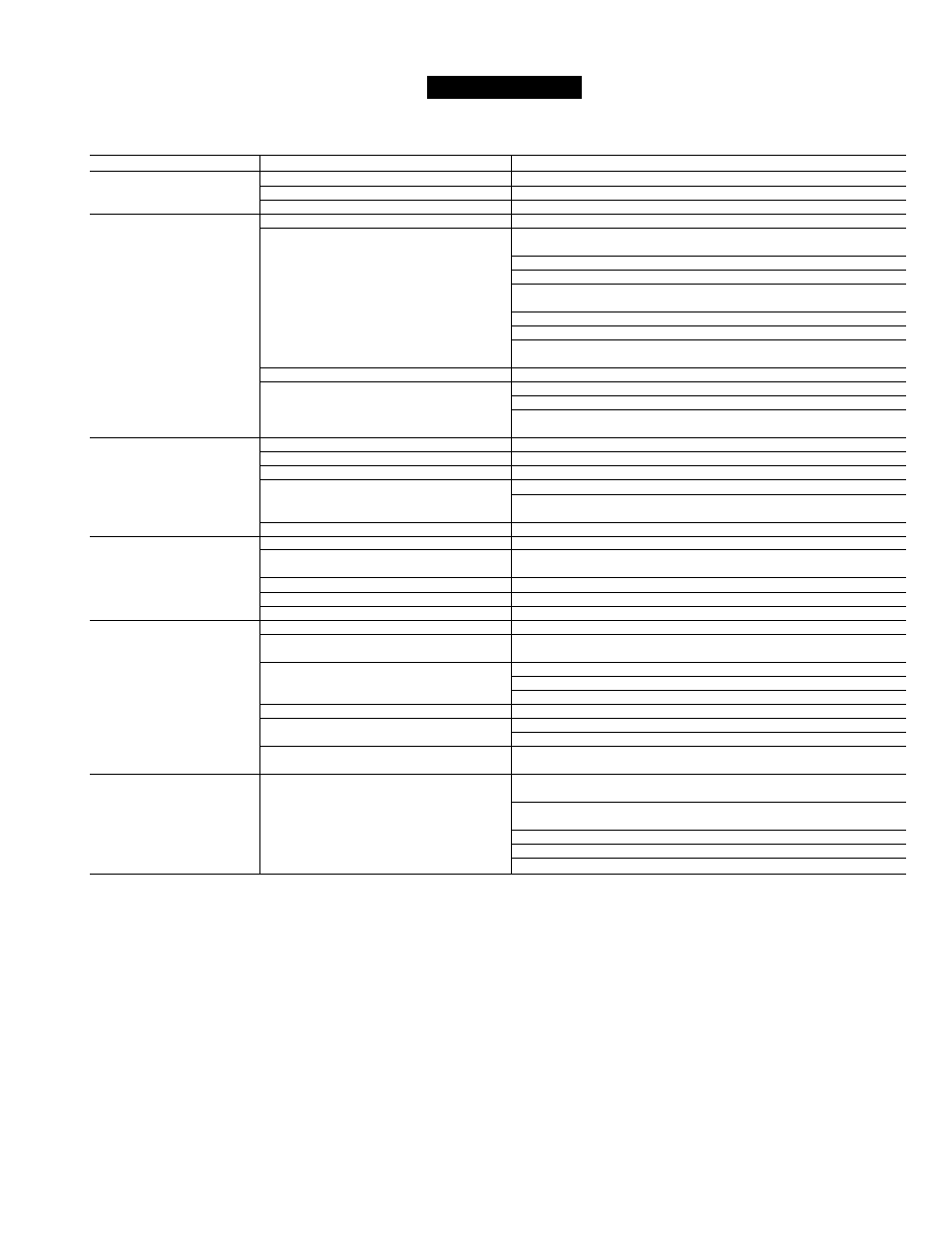

Table 6—Trouble Analysis Chart

A W A R N I N G

To avoid possibility of fixe, explosion, electric shock, personal injury or death, turn off gas and power supply to unit

before servicing (unless specific test requires gas and electric suppHes).

SYMPTOM

CAUSE

REMEDY

Furnace will not operate

No 115-volt power to furnace

Copnnect to power supply. Check fuse, wiring, or circuit breaker.

Blower door not in place

Install furnace blower door.

Defective blower door switch

Replace switch.

Pilot will not light

Vent safety shut-off switch open

Check for vent blockage and proper installation of vent pipe.

No spark at electrode

Readjust, if necessary, so that gap between electrode tip

and pilot burner is as shown in Fig. 16.

Clean dirt or moisture accumulation from electrode ceramic with cloth.

Cracked ceramic—replace pilot electrode assembly.

Check for loose or broken wiring at and between spark generator and

electrode. Replace wire or tighten connection as necessary.

Check fuse or circuit breaker for 115-volt supply to furnace.

Check blower access panel for proper installation.

Check 24-volt input to spark generator. If you read 24 volts and above

steps have been completed, replace spark generator assembly.

Spark shorting out to main burner

Readjust electrode as specified.

No gas at pilot burner

Clean pilot orifice.

Check voltage to terminals 3 and 5 or TR and TH of gas valve.

Check for proper opening of pilot valve, broken wires, or loose

connections. If no deficiency is found, replace valve assembly.

Burners will not ignite.

No 115-volt power to furnace

Connect to power supply. Check fuse, wiring, or circuit breaker.

No 24-volt power to control circuit

Replace transformer.

Miswired or loose connections

Check all wiring and all wirenut connections.

No gas at main burners

Check voltage to terminals 1 and 2 or TR and TH of gas valve.

Check for proper opening of main gas valve, broken wires, or loose

connections. If no deficiency is found, replace gas valve assembly.

Dirty pilot—yellow flame

Clean pilot orifice.

Blower operates continuously

Thermostat fan switch in ON position

Move thermostat fan switch to AUTO position.

Fusible link blown

Correct combustion air, vent system, and/or heat exchanger

blockage—replace fuse link with identical part.

Dirty filter causing limit operating

Clean or replace dirty air filter—reinstall.

Defective heat relay

Replace printed-circuit board.

Vent safety shut-off switch open

Check for vent blockage and proper installation of vent pipe.

Inadequate heating

Furnace undersized for application

Replace with proper size furnace.

Gas input to furnace too low

Check gas pressure at manifold. Clock gas meter for input. If too low,

increase manifold pressure or install correct orifices.

Limit switch cycles main burners

Clean or replace dirty air filter—reinstall.

Increase blower speed.

Open registers—ductwork restricted.

Manual reset limit switch contacts open

Blower motor failure—replace motor.

Manual reset switch contacts open (Burner

on time must be minutes minimum.)

Check and adjust thermostat anticipator to proper setting.

Replace with proper size furnace.

Thermostat anticipator set too low

Check thermostat circuit amps and set anticipator accordingly.

See Fig. 6.

Aldehyde odors, (CO),

sooting flame-

floating flame

Incomplete combustion—

poor flame characteristics

Adjust air shutter on burners to provide soft blue flame. Check all

screws around flue outlets and burner compartment. Tighten.

See “Section II, Location & Air for Combustion & Ventilation”

(Procedures for Natural-Draft Gas-Fired Furnaces).

Replace cracked heat exchanger.

Reduce input and check orifices—furnace overfired.

Check vent for restriction.

1 1