A warning, A caution – Carrier 58DR User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

3. Blower Circuit

With power through the solid-state time-delay circuit on

printed-circuit board PCB and heat relay HFR, blower

motor MTR is energized on heating speed approximately 75

seconds after gas valve GV has been energized (or the pilot

flame has been proven in the case of IID systems).

4. Limit Control

If the furnace overheats for any reason, limit control LS

switches, breaking the circuit to automatic gas valve GV.

The gas valve closes immediately, stopping gas flow to the

main burners and the pilot. In addition, blower motor MTR

continues to operate because heat relay HFR is deenergized

to cool down the furnace.

Manual reset auxiliary limit switch ALS is located on the

top right-hand comer of the furnace. In the event of blower

motor failure, this switch breeiks the electrical circuit to the

gas valve, stopping gas flow to the main burners. The

switch must be manually reset after the blower motor has

been replace.

Fusible link FL is provided in the transformer TRAN sec

ondary circuit as protection from overheating conditions in

the vestibule area of the furnace. Should this condition

exist, the fuse opens and deenergizes gas valve GV and heat

relay HFR, stopping the gas flow to the burners and start

ing blower motor MTR.

When the thermostat is satisfied, the circuit between R and

W is broken, deenergizing automatic gas valve GV, pilot SP

(when used), and the solid-state time-delay circuit on

printed-circuit board. The gas flow stops immediately to the

pilot Emd main burners with the IID controls, and to the

main burners only with standing pilot controls. After

approximately 105 seconds, heat relay HFR is energized

and blower motor MTR stops.

5. Vent Safety Shut-off System Switch

The purpose of this control is to safely shutdown the fur

nace if a completely blocked vent condition occurs.

During a blocked vent condition, temperature in the

drafthood relief opening wfll rise causing vent safety shut

off switch to open, breaking the circuit to gas valye GV. The

gas valve closes immediately, stopping gas flow to the main

burners and pilot, and the blower wfll run continuously.

The furnace wiU remain in this mode until the vent safety

shut-off system switch is manually reset.

B. Vent Damper (When Used)

With gas and electrical power supplied to the furnace, the

vent damper motor is deenergized, and the vent damper is

closed until the thermostat “calls for heat.”

On a “call for heat” by the thermostat, the vent damper

motor is energized and the deunper opens. When the vent

damper reaches the full-open position, the damper motor is

deenergized and a circuit is completed to the main gas valve

via the pilot. At this time, the main gas valve is energized

and the main burners are ignited; the vent damper will

remain open until the thermostat is satisfied.

When the thermostat is satisfied, it wfll deenergize the main

gas valve and stop the gas flow. The vent damper motor wfll

energize and close the damper. When the vent damper

reaches the full-closed position, the damper motor is

deenergized and will remain so until the next “call for heat”

by the thermostat.

C. Cooling (Cooling Models Only)

When the thermostat “calls for cooling,” power from trans

former TRAN energizes the condensing unit contactor, cool

ing relay coil CFR, closing its contacts and energizing

blower motor MTR on its cooling speed. It continues to

operate until the thermostat is satisfied.

When the thermostat is satisfied, the circuit to terminal Gc

is broken, deenergizing cooling relay coil CFR which, in

turn, opens its contacts, stopping blower motor MTR.

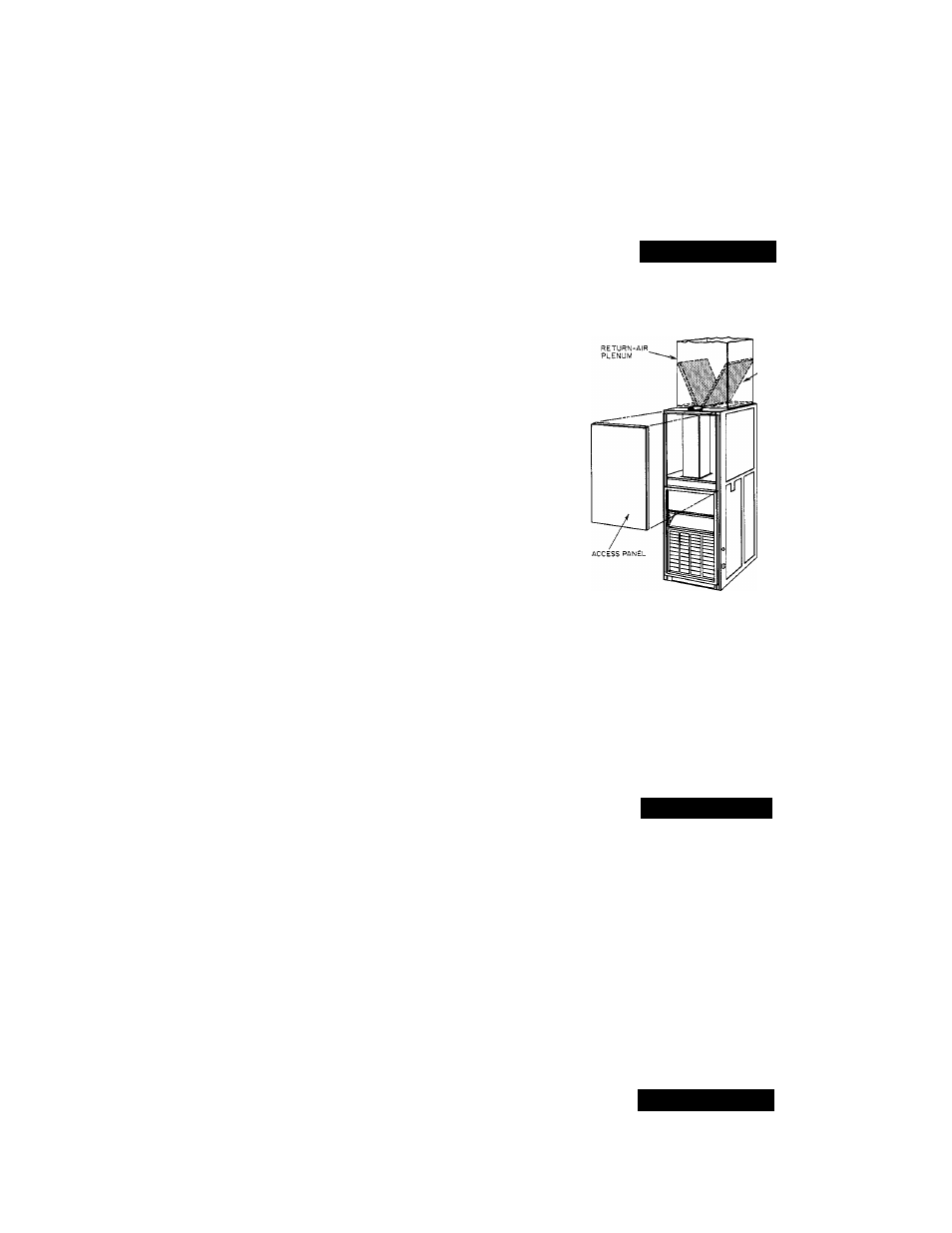

VIII. FILTER ARRANGEMENT

The two factory-supplied filters are shipped in the blower

compartment. After the return-air duct has been connected

to the furnace, install the filters hi a V-formation inside the

return-air plenum. See Fig. 11.

A WARNING

Never operate the unit without a filter or with the filter

access door removed. A failure to adhere to this warn

ing can cause a fire, physical injury, or death.

,-INSTALLATION

POSITION

OF FILTERS

A78654

Fig. 11—Position of Fiiters

IX. STARTUP AND ADJUSTMENT

In addition to the following information, refer to “Proce

dures for Natural-Draft Gas-Fired Furnaces” packaged with

the unit.

NOTE:

There is a switch located in the blower compartment

that breaks the electrical power supply when the blower

access door is removed. Be sure the blower access door is

properly installed.

A CAUTION

This furnace is equipped with a fusible link in the vesti

bule area that wfll melt if an overheating condition

caused by an inadequate combustion-Eur supply or

improper venting practices develops.

Do not

jumper

this fuse. Correct the condition and replace the fuse

with an identical part.

The gas service pressure must not exceed 0.5 psig (14

in. wc).

NOTE:

The gas valve regulator has been nominally-set at

3.5 in. wc for natural gas. Refer to “Procedures for Natural-

Draft Gas Furnace Installation” for readjusting when

checking input.

A. Adjustment of Blower Speed

A WARNING

Disconnect the electrical power before changing the

speed tap. A failure to adhere to this warning can cause

personal injury.