A caution, A warning, 58ed,pb horizontal gas-fired furnaces – Carrier 580PB User Manual

Page 4: Table 4 — draft hood dimensions (in.), Caution, Warning

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

r

HEATING & COOLING

58ED,PB

Horizontal Gas-Fired Furnaces

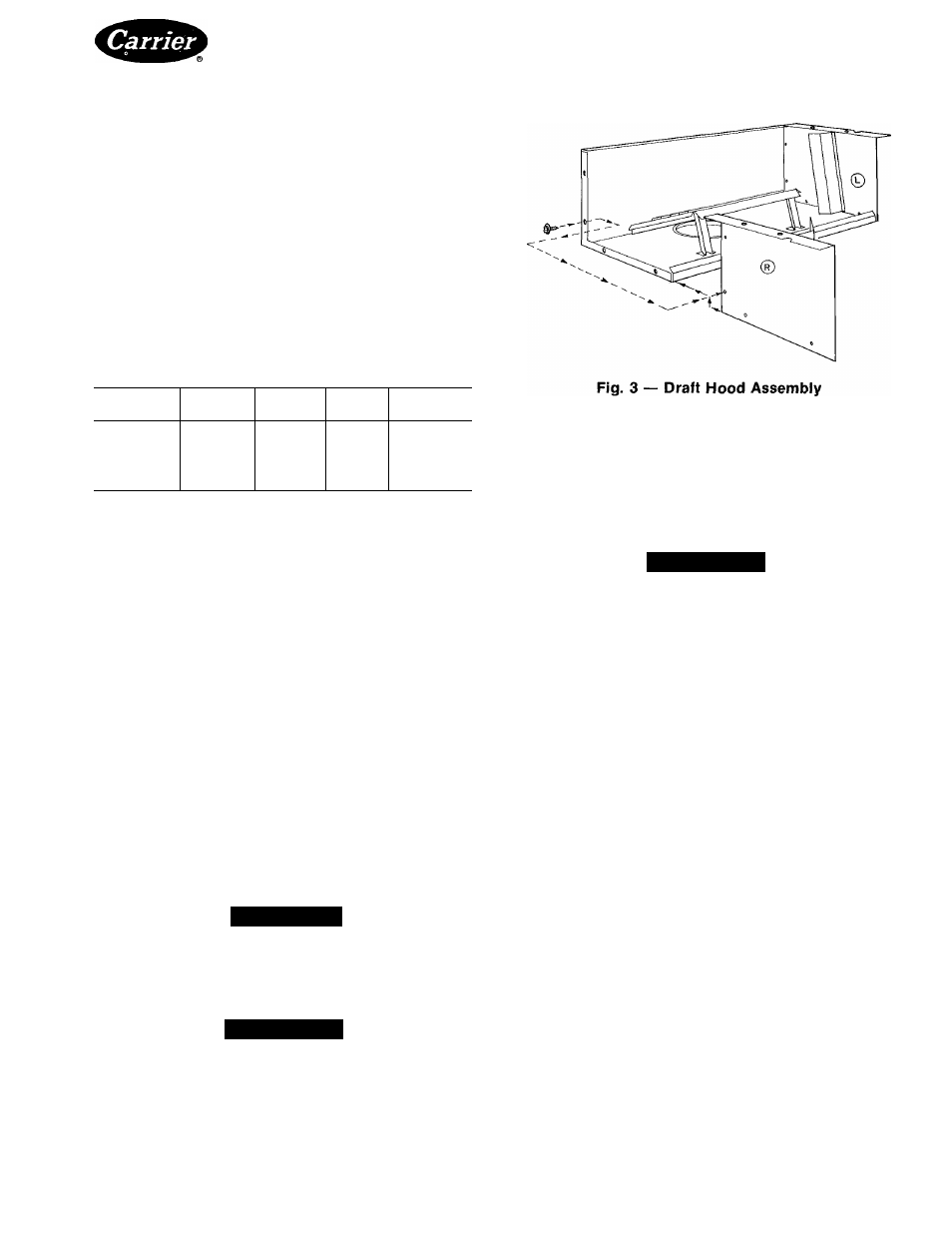

be a wrapper, 2 panels (one marked with an “R”, the

other marked with an “L”) and a hardware package.

Refer to Fig 3 to assemble the draft hood. Depending

on the model, one or both panels are slid into the proper

location in order to line up the 4 mounting holes. Secure

the panel(s) with the screws provided

After completing the draft hood assembly, it is

advisable to check the overall size with Table 4.

Install the draft hood over the selected flue opening by

placing it on top of the draft hood clip and securing it to

the furnace jacket with screws provided. Adhere to the

necessary clearances as shown in Table 3.

Table 4 — Draft Hood Dimensions (in.)

FURNACE

58ED/PB

LENGTH

HEIGHT

DEPTH

PIPE DIA.

050

16

10

8

4

075

16

10

8

4

100

16

10

8

5

125

17'/4

10

8

5

140

17'/4

10

8

6

Step 4 — Size Ductwork

— Proper ductwork sizing

is necessary to ensure satisfactory heating operation

Ductwork should be in accordance with the latest editions

of NFPA-90A (Air Conditioning Systems) and NFPA-

90 B(Warm Air Heating and Air Conditioning Systems).

Follow these recommendations when installingductwork:

1. Install locking-type dampers in all branch or indi

vidual ducts to balance out system. Dampers should

be adjusted to impose the proper static pressure at

the outlet of the furnace.

2

Noncombustible flexible duct connectors are recom

mended to connect both the supply and return ducts

to the furnace

3 In cases where the return air grille is located close to

the fan inlet, there should be at least one 90 degree air

turn between fan and inlet grille. Further reduction

in sound can be accomplished by installing acoustical

air turning vanes and/ or lining the inside of duct with

acoustical material.

A

CAUTION

Air openings in burner cover, return air grilles, and

warm air registers must not be obstructed.

A

WARNING

When supply ducts carry air circulated by the furnace

to areas outside the spaces containing the furnace,

return air shall also be handled by a duct sealed to

the furnace casing and terminating outside the space

containing the furnace.

When installing the furnace with cooling equipment

for year-round operation, the following recommenda

tions should be followed for series or parallel airflow:

1. In series airflow applications, the coil is mounted

after the furnace in an enclosure in the supply air-

stream. The furnace blower is used for both heating

and cooling airflow.

A

WARNING

The coil must be installed on the air discharge

side of the furnace. U nder no circumstance should

the airflow be such that cooled, conditioned air

can pass over the furnace heat exchanger. This

causes condensation in the heat exchanger and

possibly early failure due to rust.

2. In parallel flow installation, dampers must be pro

vided to direct air over the furnace heat exchanger

when heat is desired and over the cooling coil when

cooling is desired.

IMPORTANT: The dampers should be adequate

to prevent cooled air from entering the furnace,

and if manually operated, must be equipped with

means to prevent operation of either the cooling

unit or furnace unless the damper is in the

full cool or heat position.

Step 5 — Vent Furnace

— This furnace must be

vented to the outside and in accordance with local codes

or requirements of the local utility. In the absence of local

codes, venting should conform to the requirements of

the National Fuel Gas Code (NFPA 54-1984/ANSI

Z223.1-1984 Part 7).

For additional venting information, refer to ANSI/

NFPA 211 Chimneys, Fireplaces, Vents and Solid Fuel

Burning Appliances.

This furnace must not be vented into a solid fuel

burning chimney. The chimney must be checked for

deterioration.

Correct

the

condition

before

venting

the furnace into the chimney. The chimney must be

properly lined and sized per National Fuel Gas Code

(ANSI Z223.1-1984/NFPA-54, 1984).

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book|1 14

PCiOl

Catalog No 535-834

Printed in U S A

Form 58ED,PB-1SI

Pg4

6-85

Replaces: 58PB-1SI

For replacement items use Carrier Specified Parts.

Tab l6al8a