Start-up and adjustment standing pilot models, A warning, Electronic ignition models – Carrier 580PB User Manual

Page 13: 58ed,pb horizontal gas-fired furnaces

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

HEATING & COOLING

58ED,PB

Horizontal Gas-Fired Furnaces

27. Remove the flue box cover and flue box cover gasket

and remount them where the draft hood was located.

See Fig. 12. Do not glue gasket to cover plate.

28.

Replace the draft hood support clip and the draft

hood where the flue box cover plate was located.

NOTE; All controls, wiring, draft hood and the

AG A lighting instruction plates must be located

on the same side of the furnace as the automatic

main gas valve. Reattach all wires to gas valve and

check against wiring diagram.

29. Elect}onic ignition models only: Reattach all wires

to the gas valve and the ignition cable to the ignition

control.

Check all wiring against the wiring diagram. Fig.

6 and 7.

30. After the furnace components have been reversed,

return to Step 3, Assemble Furnace Draft Hood and

proceed with remainder of installation.

START-UP AND ADJUSTMENT

Standing Pilot Models

OPERATIONAL CHECKOUT — The automatic gas

valve controls the flow of gas to both the pilot and

main burners. The manual valve built into the automatic

valve body has 3 positions- OFF, PILOT, and ON.

SEQUENCE OF OPERATION — The furnace operates

automatically. It is controlled by a thermostat which is

set at the desired temperature. When indoor temperature

/ drops below this setting, the thermostat turns on the

system.

When the thermostat calls for heat, power from the

transformer energizes the main gas valve (the pilot must

be lit already) and gas flows through the valve to the

burners. The pilot flame lights the burners.

A heat sensing switch automatically energizes the

blower when heat buildup is sufficient. The air is moved

by the blower over the heating element, thus warming it,

and it goes through the ducts to room registers.

When the thermostat is satisfied, the circuit is broken,

de-energizing the main gas valve and stopping gas flow

to the main burners.

The blower continues to run until the heat in the heat

exchanger is removed and then the sensing switch shuts

off the blower.

All forced air furnaces are equipped with a high

temperature limit switch which prevents the furnace

from overheating. If the furnace overheats for any

reason, the high temperature limit opens, breaking the

circuit to the gas valve. The blower motor continues to

run. The main burners cycle on limit until the fault is

corrected.

A

WARNING

If overheating occurs, or if the gas supply fails to

shut off, shut off the manual gas valve to the furnace

before shutting off the electrical supply.

Electronic Ignition Models

OPERATIONAL CHECKOUT — The automatic gas

valve controls the flow of gas to both the pilot and main

burners. The manual valve built into the automatic valve

body has 2 positions: OFF and ON.

SEQUENCE OF OPERATION — The furnace operates

automatically. It is controlled by a thermostat which is

set at the desired temperature. When indoor temperature

drops below this setting, the thermostat turns on the

system.

When the thermostat calls for heat, power from the

transformer simultaneously energizes the pilot gas valve

(inside the main gas valve) and the spark igniter. After

the pilot flame is established, the electrode ceases to

spark and the flame sensing probe acts to energize the

main gas valve, permitting gas flow to the burners.

A heat sensing switch automatically energizes the

blower when heat buildup is sufficient. The air is moved

by the blower over the heating element, thus warming it,

and it goes through the ducts to room registers.

When the thermostat is satisfied, the circuit is broken,

de-energizing the main gas valve and stopping gas flow

to the pilot and main burners. The blower continues to

run until the heat in the heat exchanger is removed and

then the sensing switch shuts off the blower.

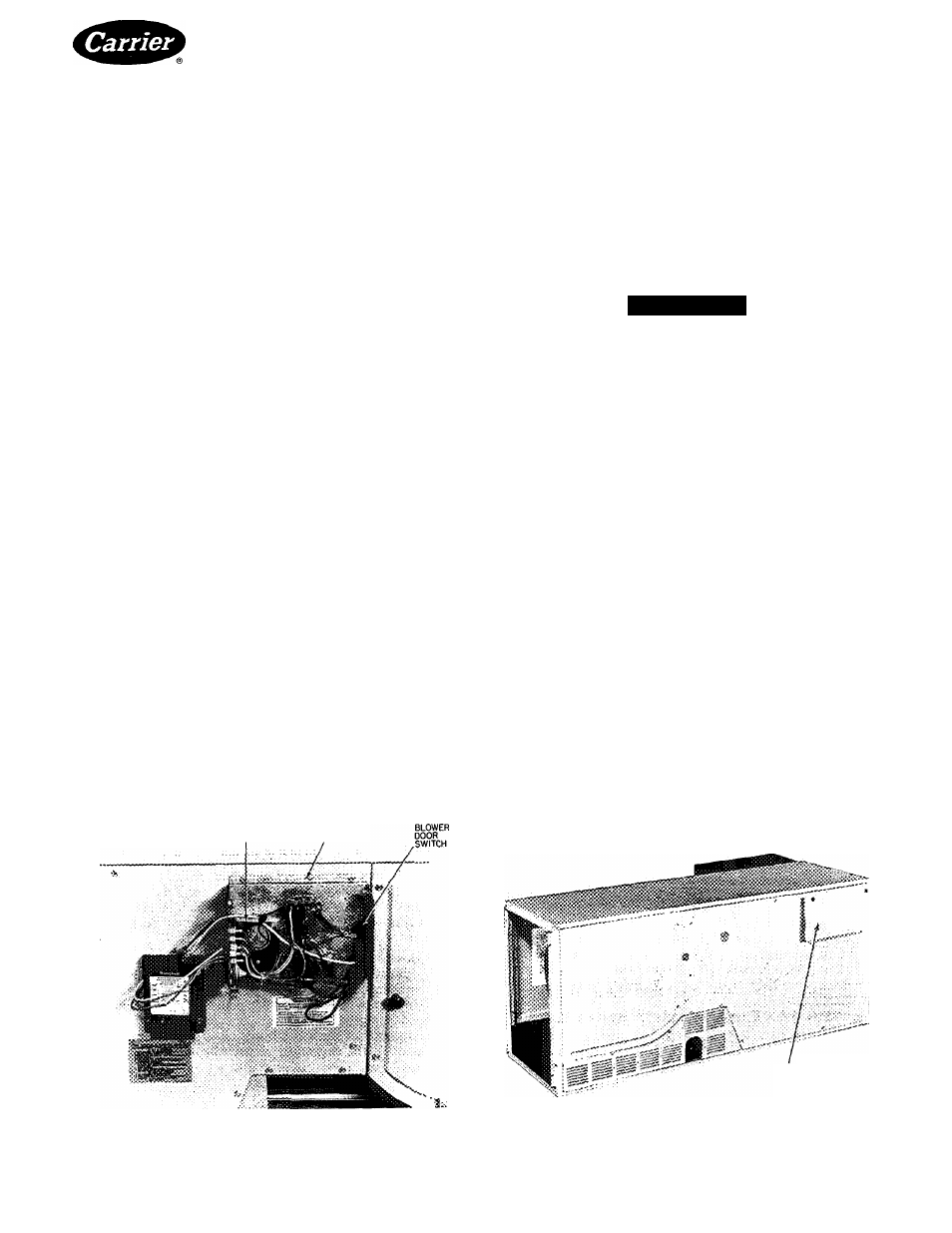

JUNCTION

BOX

Fig. 11 — Junction Box

(Model 58ED Shown)

FLUE BOX

COVER

(GASKET IS

UNDERNEATH)

Fig. 12 — Flue Box Cover

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

BookH 14

PC101

Catalog No 535-834

PrintedinUSA

Form 58ED,PB-1SI

Pg 13

6-85

Replaces: 58PB-1 SI