Introduction, Installation, Complete pre-installation checks – Carrier 19QA User Manual

Page 2

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

CONTENTS

Page

SAFETY CONSIDERATIONS .....................................

INTRODUCTION .........................................................

2

INSTALLATION ..........................................................

2-7

Complete Pre-Installation Checks............................

• IDENTIFY UNIT

• INSPECT SHIPMENT

Make Piping Connections .........................................

2

Make Electrical Connections ....................................

2

Optional Caster Installation ......................................

2

CONTROLS AND COMPONENTS.............................

Pump and Motor .........................................................

7

Oil Separator...............................................................

7

Heater ..........................................................................

7

Tube-in-Tube Condenser...........................................

7

Level Gage ..................................................................

7

Water Separation Sight Glass ..................................

7

Purge Separator Assembly.......................................

7

Refrigerant Hoses ......................................................

8

Liquid Indicator..........................................................

8

Filter Drier ...................................................................

8

OPERATION .............................................................

Evacuation ..................................................................

9

Liquid Refrigerant Transfer.......................................

• BEFORE TRANSFERRING LIQUID

REFRIGERANT

• TO TRANSFER LIQUID REFRIGERANT

Refrigerant Vapor Transfer ......................................

• BEFORE TRANSFERRING REFRIGERANT

VAPOR

• TRANSFER REFRIGERANT

Purge Separator Assembly ......................................

12

Oil Separation ............................................................

12

Water Separation .......................................................

13

MAINTENANCE .........................................................

Maintaining the Pump ..............................................

15

Pump Coupling .........................................................

15

High-Pressure Cutout Switches..............................

15

Refrigerant Storage Tank.........................................

15

Refrigerant Hoses.....................................................

15

TROUBLESHOOTING................................................

INTRODUCTION

The 19QA Refrigerant Management System (RMS) has

been designed to help owners and operators of centrifugal

chillers conserve low pressure refrigerants and prevent the

release of excessive amounts of refrigerant into the atmo

sphere. The proper use of this equipment will minimize the

loss of CFCs and HCFCs. The 19QA will also recycle re

frigerant contaminated with water, oil, or acid. See Fig. 1

and Table 1 for component information.

The 19QA is ARI (Air Conditioning & Refrigeration In

stitute) certified as a refrigerant recovery/recycling device

and is registered with ETL (Electrical Testing Laboratory)

for safety. The Refrigerant Management System’s storage

tanks are rated for 20, 30, or 40 cu ft (.57, .85, 1.13 cu

meters). See Table 2. Casters are available as an option on

all storage tanks. See Fig. 1-3. See Fig. 4 and 5 for addi

tional RMS component descriptions and dimensions.

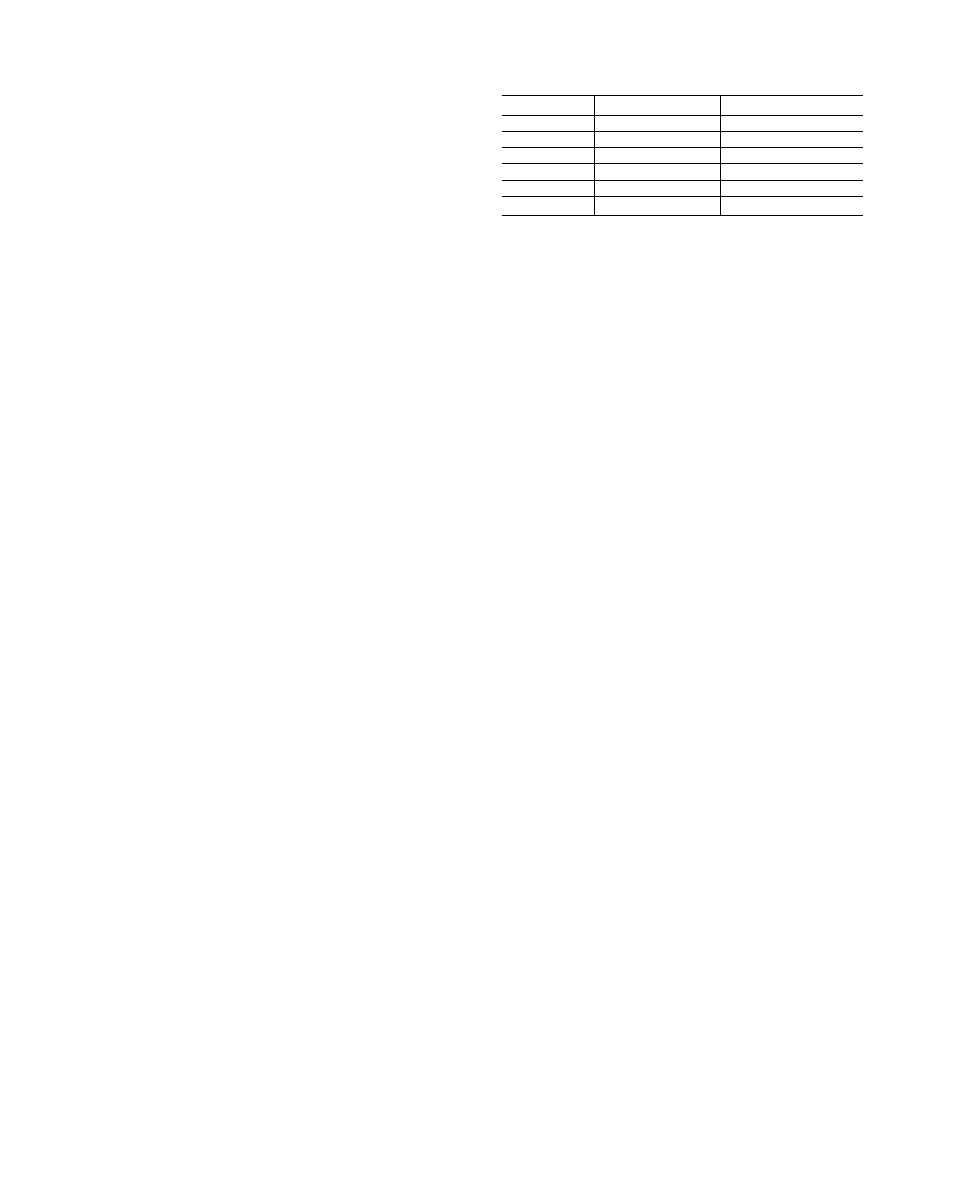

Table 1 — Interconnecting Refrigerant Hoses,

Valves, and Fittings

NUMBER

PART NUMBER

PART

1

KA73PS003

3 ft (.91 m) Hose

2

KA73PS006

6 ft (1.88 m) Hose

1

KA73PS012

12 ft (3.66 m) hose

1

19QA020-152

Liquid Indicator

8

19QA020-132

Valve and Coupler

1

19QA015-142

Chiller Vapor Valve

NOTE: Refer to Fig. 1 for model number description and accessory

caster package part numbers.

INSTALLATION

Complete Pre-Installation Checks

IDENTIFY UNIT — Identify the model number and serial

number printed on the nameplate. Check this information

against the job requirements.

INSPECT SHIPMENT — Inspect unit for damage before

removing unit from shipping conveyance. If unit appears

damaged, it should be inspected by a shipping inspector be

fore removal. File claim with shipping company if ship

ment is damaged or incomplete. The manufacturer is not

responsible for damage incurred during transit.

Check all components. Notify the supplier immediately

if any item is missing. To prevent loss or damage, leave all

parts in their original package until they are needed.

Make Piping Connections

— All connections be

tween the pump, tube-in-tube condenser, storage tank, and

chiller can be made using the factory supplied refrigerant

hoses. A hand valve with coupler is factory supplied, but

must be field installed at each end of the 4 hoses. See

Fig. 5. Field supplied copper tubing and valve manifolds

must be used if a permanent installation is required.

The 19QA is factory equipped with a dual relief valve

assembly. See Fig. 4. The outlet of the valves is 1-1/2 in.

MPT. Vent the dual relief assembly outdoors in accordance

with ASHRAE 15 (Safety Code for Mechanical Refrigera

tion), latest edition, and all applicable local codes. Use a

minimum 1-1/2 in. pipe for the relief valve outlet. Provide

fittings so vent piping can be disconnected periodically for

inspection and testing of valves.

Cover the outdoor vent with a rain cap and place a field

supplied condensate drain at the low point in vent piping to

prevent water build up on the atmospheric side of the valve.

Make Electrical Connections

— The 19QA has 2

electrical cords. See Table 3 and Fig. 6. One electrical cord

is attached to the pump and the other is attached to the stor

age tank heater. If both electrical cords are used at the same

time, separate outlets are required. Connect electrical power

in accordance with minimum circuit amps (MCA) and max

imum overcurrent protection amps (MOCP) as specified on

the unit nameplate. Be sure that the unit is connected and

grounded in accordance with all applicable electrical codes.

Optional Caster Installation

— if optional casters

have been provided, bolt the 4 caster assemblies to the stor

age tank. See Fig. 1-3. Size 020 and 030 storage tanks have

2 rigid casters mounted on one end of the tank and 2 swivel

casters with brakes mounted on the other end of the storage

tank. The size 040 storage tanks have 2 swivel casters with

brakes mounted on one end of the storage tank and 2 swivel

casters with locks mounted on the other end of the storage

tank.