Carrier 19QA User Manual

Page 13

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Water Separation

— Water is only slightly soluble in

refrigerant. See Table 4. If additional water is present, it

will float on top of the refrigerant and can be easily re

moved by the RMS unit.

Transfer the water contaminated refrigerant to the stor

age tank using the procedures described in the Liquid Re

frigerant Transfer section. If the refrigerant contamination

was caused by a chiller failure, the chiller must be repaired,

dehydrated, and vacuum broken with refrigerant. Use

24 in. Hg ( - 8 1 kPa) for CFC-113, 18 in. Hg ( - 6 1 kPa)

for HCFC-123, and 15 in. Hg ( - 5 1 kPa) for CFC-H to

avoid freezing the tubes in chiller before the cleaned liquid

refrigerant can be returned to the chiller. If the chiller is not

repaired, the clean refrigerant should be transferred to an

other clean tank.

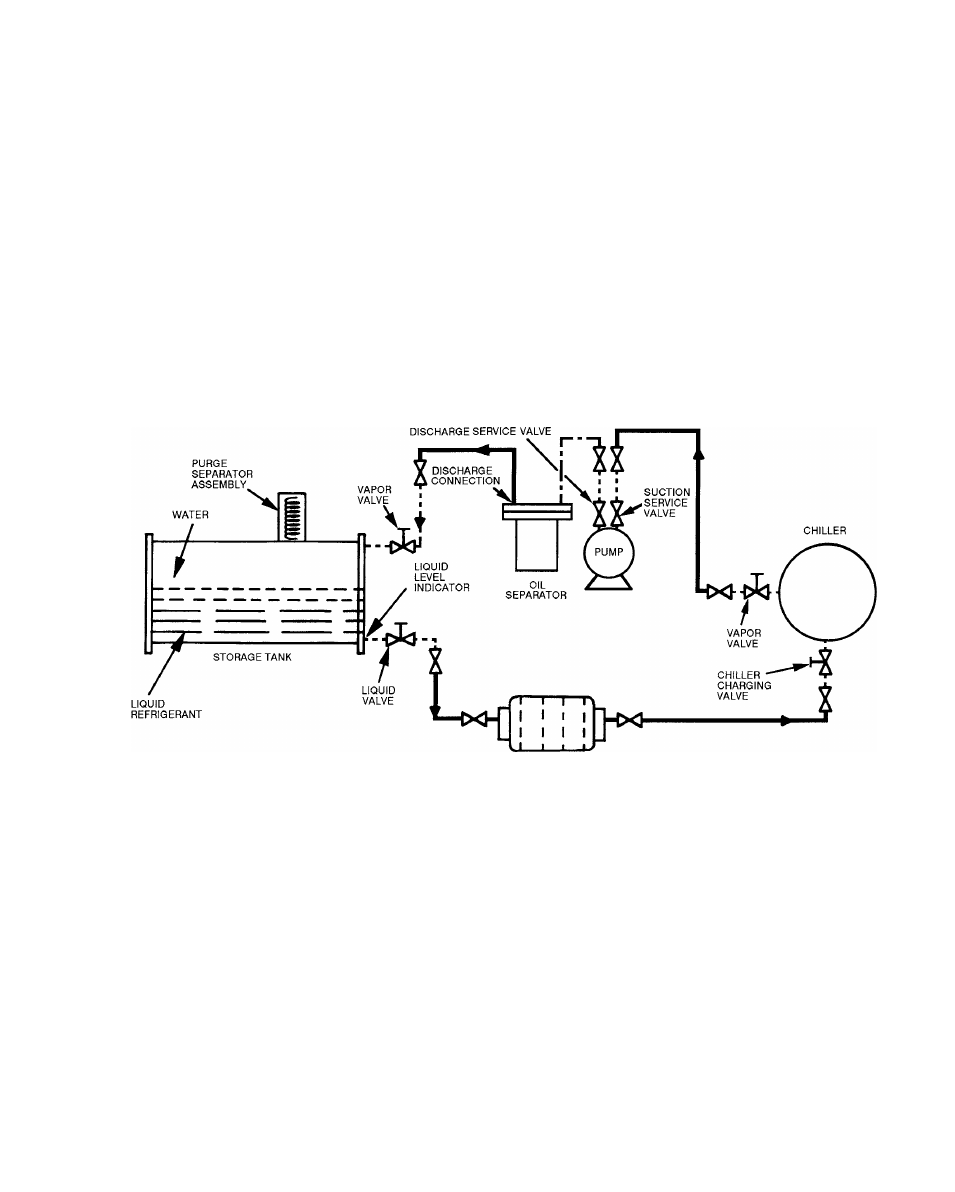

Connect the 12-ft refrigerant hose from the chiller or clean

storage tank vapor valve to the suction service valve on the

pump. See Fig. 14. Copper tubing is factory installed from

the pump to the oil separator. Connect a 6-ft refrigerant

hose from the discharge connection of the oil separator to

the vapor valve on the storage tank. Connect the 3-ft refrig

erant hose and liquid level indicator from the liquid valve

of the storage tank to the filter drier canister. See Fig. 5.

Connect the remaining 6-ft refrigerant hose from the filter

drier canister to the chiller charging valve or the liquid valve,

if using a storage tank. Open all valves between the storage

tank and the chiller. Turn on the pump.

While the liquid refrigerant is being transferred into the

chiller or another storage tank, use the water separation glass

at the bottom of the tank to determine when the water/

refrigerant level is close to the liquid valve. See Fig. 4. Re

duce the liquid flow rate as the water level approaches the

liquid valve. Close the liquid valve when the water/

refrigerant level is at the bottom of the water separation

glass to prevent water from entering the other storage tank.

To prevent the loss of remaining refrigerant, transfer the

water/refrigerant mixture into an open container. Skim the

water off the top of the refrigerant. Transfer the remaining

refrigerant into the storage tank.

FILTER DRIER

Refrigerant Hose

Direct Coupled Connection

Factory-Installed Copper Tubing

Fig. 14 — Water Separation

13