Viii. filter arrangement, Ix. sequence of operation – Carrier 58DHL User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

hanger bolts (Four each %-in. all-thread rod) cut to desired

length, 1 X % flat washer, % lockwasher, and % nut. Dimples

are provided for hole locations. See Fig. 3.

NOTE:

Use Type B1 vent in a concealed space.

The crawl space installation is very similar to the attic;

therefore, refer to Division VI, Section B, steps 1, 2, and 3.

The installation of a sheet metal shield in front of the lou

vered control panel is covered in step 4. For a crawl space

installation, this same sheet metal shield must be installed

above the louvered control panel. Extend the sheet metal

shield over the furnace top far enough to cover the gas pipe

entry hole.

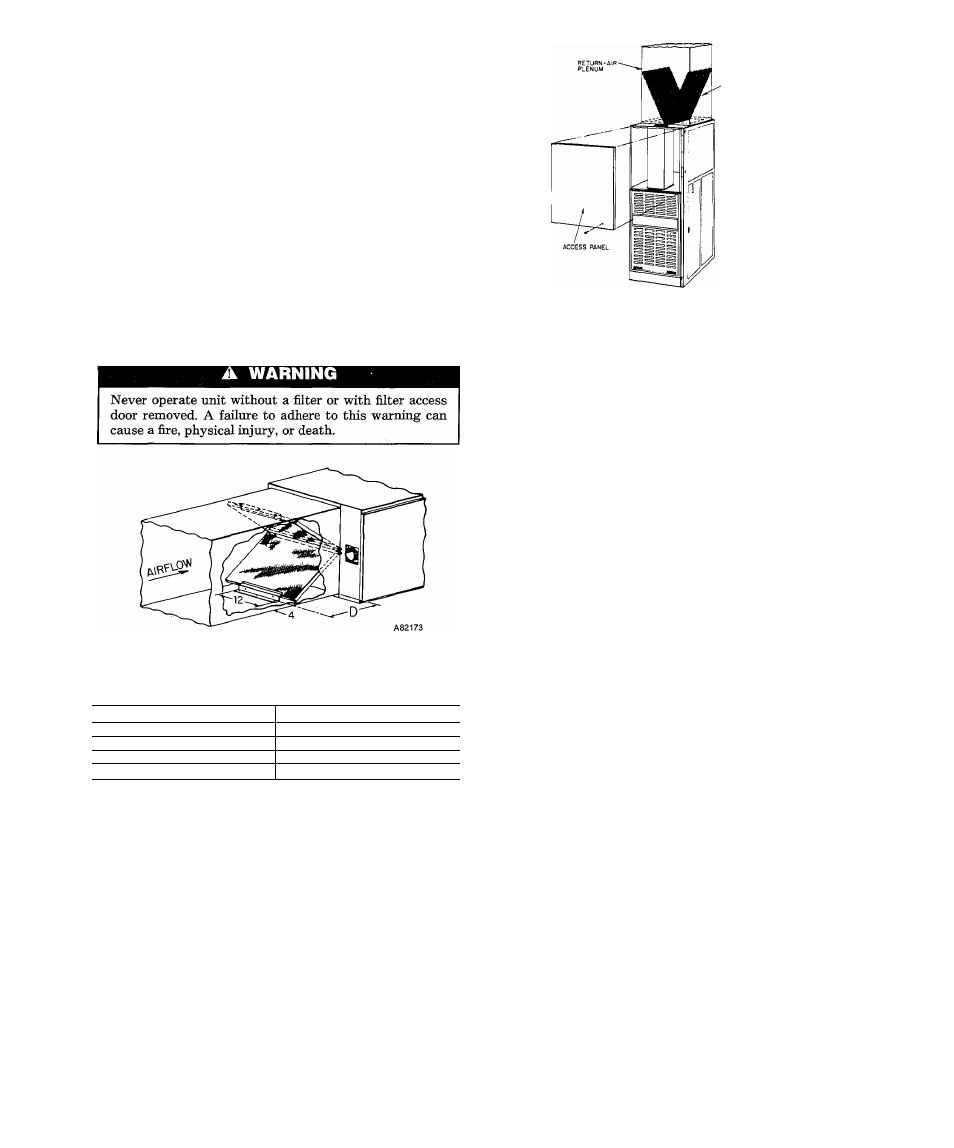

VIII. FILTER ARRANGEMENT

The two factory-supplied filters are shipped in the blower

compeirtment. After the return-air duct has been connected

to the furnace, install the filters in a V-formation inside the

return-air plenum. See Fig. 10 and Table 5 for horizontal

applications. See Fig. 11 for downflow applications.

Fig. 10—Horizontal Filter Arrangement

Table 5—Filter Retainer

Furnace Casing Width

D

14^,6

15=As

M'k

1472

21

13%6

2Vk

1274

IX.

SEQUENCE OF OPERATION

Using the schematic wiring diagram. Fig. 12, trace the

sequence of operation for the heating cycle is as follows:

1. When the blower door is in place, 120 volts is supplied

through blower door interlock switch 9G. Transformer

lA is energized, supplying 24 volts to heating-blower

relay coil 2E, which opens normally closed blower relay

contacts 2E in the low-speed circuit of blower motor

3D.

2. The wall thermostat “calls for heat,” closing the R and

W circuit. This closed circuit supplies power to the 24-

volt safety circuit containing hmit switch 7H1, fusible

link lie, manual-reset draft-safeguard switch 7H2, and

manual reset auxfliary switch 7H3.

3. Simultaneously, the pilot solenoid coil of gas valve 5F,

spark generator 6F, and inducer-motor relay coU 2D

are energized. Inducer-motor relay contacts 2D in the

120-volt circuit close, starting inducer blower motor

INSTALLATION

POSITION

OF F

ilters

A82179

Fig. 11—Position of Filters

3A. Also, another set of contacts in inducer-motor

relay 2D close in the 24-volt circuit, and lock in

inducer-motor relay coil 2D. The coU is locked in until

the R and W circuit or safety circuit opens.

4. When the pilot solenoid coil of gas valve 5F is ener

gized, gas flows to the pilot. The pressure switch

within the gas valve senses the pilot gas pressure and

closes. The pilot gas is ignited by a spark produced by

spark generator 6F. Simultaneously, inducer motor 3A

comes up to speed, actuating flow sensing switch 7V,

which supphes 24 volts to the hold circuit of gas valve

5F. After a short delay, the normally closed contacts of

the pilot-flame sensing switch 6H opens. The pilot sole

noid cofl. remains energized through the hold circuit,

while the spark generator 6F shuts off within a few sec

onds after ffame is sensed at the spark electrode. The

normally open pilot-flame sensing contacts close 5 to

20 seconds later, making the circuit to the MVG (Main

Operator) of gas valve 5F. Gas valve 5F opens 6 to 15

seconds later allowing gas flow to the meun burners,

which are ignited by pilot 6H. Simultaneously, time-

delay circuit IIL in the blower control center is ener

gized. Approximately 50 seconds after gas valve 5F

opens, heating relay coil 2E is deenergized, which

closes the 120-volt contacts of heating relay 2E, start

ing blower motor 3D on its heating speed.

5. When the thermostat is satisfied, the circuit between R

and W is broken, deenergizing gas valve 5F, inducer

motor relay 2D, and the solid-state time-delay circuit

on the printed-circuit board. The gas flow stops imme

diately to the pilot and main burners. After approxi

mately 105 seconds, heat relay 2E is energized and

blower motor 3D stops.

NOTE:

After a brief interruption of either electric or gas

supply, the furnace will not resume operation until the con

tacts of pilot-flame sensing switch 6H move from the nor

mally open to the normally closed position.

Cooling Cycle

1. The wall thermostat “calls for coohng.”

2. The R, G, and Y circuits are energized. Simultaneously,

the R-and-Y circuit starts the outdoor condensing unit,

and the R-and-G circuit energizes cooling relay coil 2F,

which closes normally open contacts 2F, energizing the

cooling speed winding of motor 3D and opening the

normally closed contacts of cooling relay 2F.

X. ELECTRICAL CONNECTIONS

A. Line-Voltage Wiring

IMPORTANT: Before proceeding with the electrical con

nections, make certain that voltage, frequency, and phase