Tabie 3—ratings and performance, V. supply-air plenum installation (downflow) – Carrier 58DHL User Manual

Page 2

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

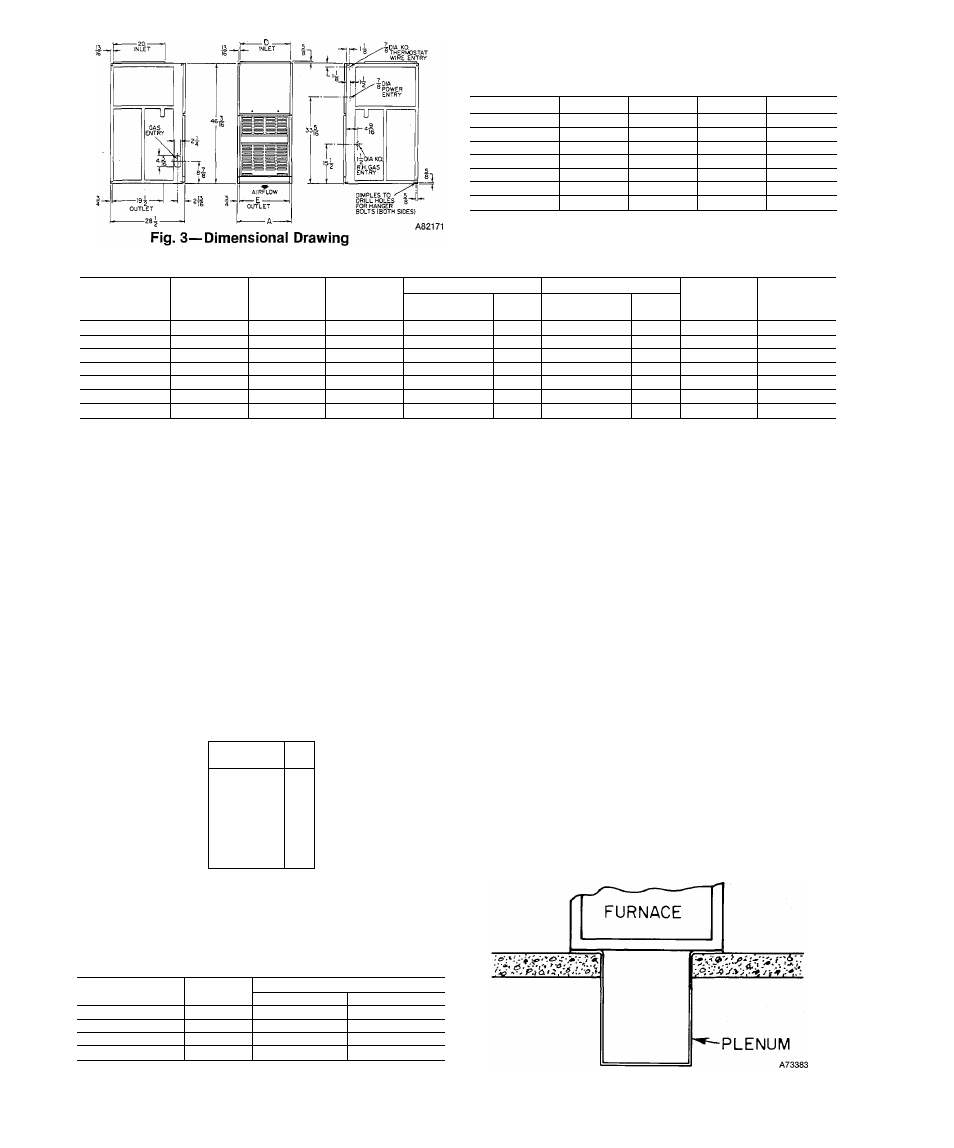

Table 2—Dimensions (in inches)

Size

A

D

E

Vent Conn

055BC

14^,6

127,6

12”/,6

4

055CC

14=/i6

127,6

12’7,6

4

OrSBC

1772

157a

16

4

075CC

V'k

157fc

16

4

095CC

M'k

157s

16

4

095DC

21

197a

1972

4

115CC

2472

22-'7,6

23

5

Tabie 3—Ratings and Performance*

SIZE

Input

Btuh*

Capacity

Btuht

Temperature

Rise

Range

Heating

Cooling

Motor

HP & Type

Shipping

Weight

(Lbs)

External Static

Pressure

CFM

External Static

Pressure

CFM

055BC

67,000

56,000

40—70

0.12

775

0.5

850

74 psc

140

055CC

67,000

56,000

35—65

0.12

1080

0.5

1157

7a PSC

142

075BC

90,000

75,000

45—75

0.15

1005

0.5

1225

7a PSC

160

075CC

90,000

75,000

40—70

0.15

1240

0.5

1553

’¿PSC

163

095CC

114,000

95,000

55—85

0.20

1248

0.5

1590

72 PSC

178

095DC

114,000

95,000

. 55—85

0.20

1350

0.5

1929

’¿PSC

188

115CC

137,000

115,000

45—75

0.20

1937

0.5

2010

’¿ PSC

208

*The above gas inputs are certified for altitudes to 2000 ft. For elevations above 2000 ft, reduce input 4% for each 1000 ft above sea level.

tDetermined by U.S. Government test.

The design of the downflow/horizontal gas-fifed furnace is

A.G.A. certified for natural and LP (propane) gas and for

installation on noncombustible flooring. The furnace may be

installed on combustible flooring when installed with the

accessory floor base. This furnace is for installation in

alcoves, attics, crawl spaces, basements, closets, or iitUity

rooms. The design of this furnace line is not A.G.A. certified

for installation in mobile homes, recreation vehicles, or

outdoors.

Installation comprises the following:

*1. Inspection

*11. Location, Ventilation, and Air for Combustion

*III. Gas Piping

HOLE IN

FLOOR

3

A73382

Fig. 4—Floor Opening for Concrete Slab

Table 4—Opening Dimensions

Furnace Casing

A

B

Width

Heat-Only

Heat/Cool*

147,6

13’¿

19%

197,6

17’¿

167,6

19%

197,6

21

19’¿

19%

197,6

24’¿

237,6

19%

197,6

*IV. Venting

V. Supply-Air Plenum Installation (Downflow)

VI. Attic Installation

VII. Crawl Space Installation

VIII. Filter Arrangement

IX. Sequence of Operation

*To perform these sections (or installation steps), refer to

the appropriate sections of “Procedures for Induced-Com

bustion Furnaces” booklet packaged with this unit.

X. Electrical Connections

XI. Startup and Adjustment

XII. Care and Maintenance

For accessory installation details, refer to apphcable instal

lation hterature.

V. SUPPLY-AIR PLENUM INSTALLATION (DOWNFLOW)

A. Installation on a concrete slab

1. See Fig. 3 for dimensions and location of supply-air

opening in furnace bottom.

2. Construct hole in floor per dimensions in Fig. 4 and

Table 4.

3. Place plenum and furnace as shown in Fig. 5.

B. installation on a combustible floor

1. Read Installation Instructions packaged with combus

tible floor base.

♦These dimensions apply when a Model 28RC or 28RD Evaporator Coil

casing is to be installed.

Fig. 5—Furnace on a Concrete Slab