Vi. horizontal attic installation, A warning, B. install furnace – Carrier 58DHL User Manual

Page 3: Vii. crawl space installation

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

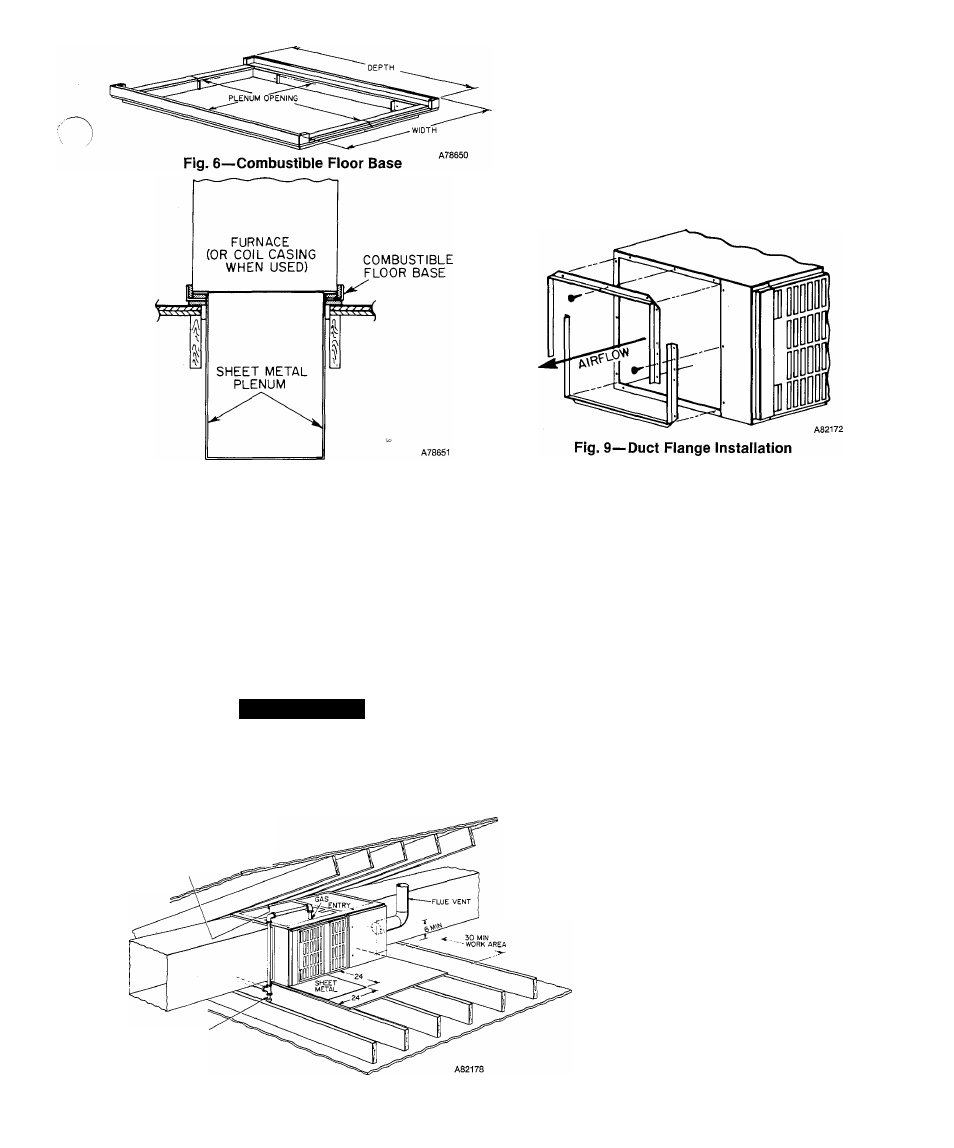

Fig. 7—Furnace, Plenum, and

Base Installed on a Combustible Floor

2

.

3.

Cut and frame hole in floor per dimensions in Table 1 of

Installation Instructions packaged with combustible

floor base. If this requires cutting of a floor joist, tie

ends of cut joist into adjacent joists so that proper

floor support wül be maintained.

Assemble and install combustible floor base per

instructions packaged with base.

4. When completed, combustible floor base, plenum, and

furnace (or coil casing when used) should be installed as

shown in Fig. 7.

VI. HORIZONTAL ATTIC INSTALLATION

A WARNING

Do not install the furnace on its back. Fusible link oper

ation will be adversely affected. Never connect return-

air ducts to the sides or back of the furnace. A failure to

adhere to this warning can cause a fire, physical injury,

or death.

LINE CONTACT ONLY PERMISSIBLE BETWEEN

LINES FORMED BY INTERSECTIONS OF

THE TOP AND TWO SIDES OF THE FURNACE

JACKET AND BUILDING JOISTS.

STUDS OR FRAMING.'

The furnace can be installed horizontally on either the LH

or RH side. A typical attic installation is shown in Fig. 8.

NOTE;

The National Fuel Gas Code requires the use of a

t

5

q>e B1 vent in an attic or concealed space.

A. Construct a working platform.

1. Place working platform in location where all required

furnace clearances are obtainable. See Table 1.

2. Use materials in platform that will support installer

and service persons.

3. Secure platform to building joists.

B. Install furnace

1. Position furnace in desired location.

2. Connect gas supply pipe. See Fig. 8 for typical piping

entry. It is important to install a sediment trap in the

gas pipe riser.

3. Connect supply- and return-air ducts.

a. Install field-supplied duct flanges as shown in

Fig. 9.

b. Using appropriate fasteners for type of supply-air

duct being used, connect duct to furnace.

c. Install field-supphed filter retainers as indicated in

Fig. 10 and Table 5 before coimecting return-air

duct to furnace.

NOTE:

For ease of servicing, a return-air filter can be

installed in a common return-air grille. The air velocity rat

ing must not exceed 300 ft/min for disposable filters. The air

velocity through permanent-type filters shall not exceed the

mEuiufacturer’s recommendation.

d. Using appropriate fasteners for type of duct being

used, connect return-air duct to furnace.

4. Install 24-x24-in. sheet metal shield on platform in

front of louvered control panel, as shown in Fig. 8.

VII.

CRAWL SPACE INSTALLATION

The furnace can be installed horizontally with either the LH

or RH side up. In a crawl space, the furnace can either be

hung from the floor joist or installed on suitable blocks or

pad. The furnace can be suspended from each corner by

SEDIMENT TRAP

Fig. 8—Typical Attic installation