A warning, A caution – Carrier 58DX User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

after MGV solenoid coil is energized, heating relay coil

HFR is deenergized, closing the 115-VAC contacts of

heating relay HFR and steirting blower motor MTR on

heating speed. The H terminal is energized with 24

VAC when the blower motor is operating on heating

speed. Electronic air cleaner terminals (EAC) are ener

gized with 115 VAC when the blower is operating on

either heating or cooHng speed.

8. When the thermostat is satisfied, the R and W circuit

is broken, deenergizing gas valve GV, and the solid-

state time-delay circuits for the inducer motor relay

IDR and blower motor relay HFR. The gas flow to the

pilot and main burners immediately stops. After

approximately 15 seconds, induced draft motor relay

IDR is deenergized and induced draft motor IDM

stops. Approximately 80 to 240 seconds (depending on

the blower off-time adjustment) after main burners are

extinguished, heating relay HFR is energized and

blower motor MTR stops.

NOTE:

After a brief interruption of either the electric or

gas supply, the furnace will not resume operation until the

contacts of pilot-flame sensing switch PS move from the

normally open position to the normally closed position.

Cooling Cycle

1. The wall thermostat “calls for coohng.”

2. The R, G, and Y circuits are energized. Simultaneously,

the R and Y circuit starts the outdoor condensing unit,

and the R and G circuit energizes cooling relay coil

CFR. Normally open cooling contacts CFR close, ener

gizing the cooling speed of motor MTR and opening the

normally closed contacts of cooling relay CFR. The

EAC terminals are energized with 115 VAC when the

blower is operating on either heating or cooling speed.

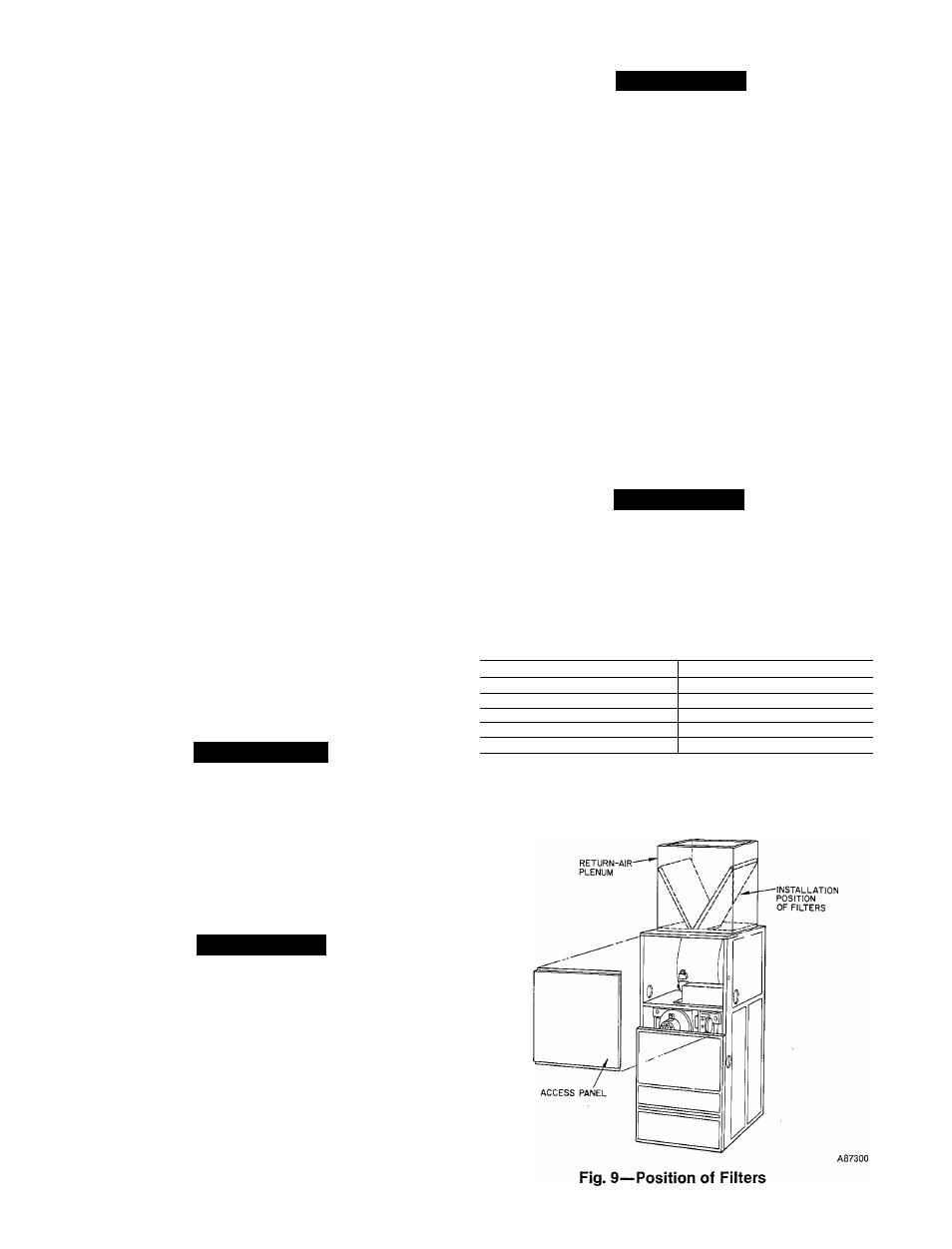

IX. FILTER ARRANGEMENT

The two factory-suppHed filters are shipped in the blower

compartment. After the retum-air duct has been connected

to the furnace, install the filters (with cross-hatch binding

facing blower) in a V-formation inside the retum-edr plenum.

See Fig. 9.

A WARNING

Never operate the unit without a filter or with the filter

access door removed. A failure to adhere to this warn

ing can cause a fire, physical injury, or death.

X. STARTUP AND ADJUSTMENT

In addition to the following information, refer to “Proce

dures for Downflow Condensing Furnaces.”

NOTE:

The furnace blower access panel must be in place to

complete the 115-volt circuit to the furnace.

A CAUTION

This furnace is equipped with a fusible link in the

burner enclosure. This link will melt if an over-heating

condition caused by an inadequate combustion-air sup

ply or improper venting practices develops. DO NOT

jumper this fuse. Correct the condition and replace the

fuse with an identical part.

The gas service pressure must not exceed 0.5 psig (14 in. wc)

for natural gas.

NOTE:

The gas valve regulator has been nominally-set at

3.5 in. wc for natural gas. Refer to “Procedures for Down

flow Condensing Furnaces” for readjusting and checking

input.

A CAUTION

The unit must not be installed, operated, and then

turned off and left turned off, in an unoccupied struc

ture during cold weather when the temperature drops

to 32 °F and below. Freezing condensate left in the fur

nace will damage the equipment.

A. When winterizing the furnace, it is necessary to

proceed as foilows:

1. Mix a solution of equal amounts of ethylene glycol

(Prestone II antifreeze coolant or equivalent) and

water.

2. Turn off electrical supply to furnace.

3. Remove control emd blower access panels.

4. Disconnect drain tube from bottom of inducer outlet

elbow.

5. Insert funnel in drain tube and pour antifreeze/water

solution into furnace until it is visible at point where

condensate enters open drain.

6. Reconnect dredn tube to outlet elbow.

7. Replace control access panel.

B. Adjustment of Blower Speed

A CAUTION

Disconnect the electrical power before changing the

speed tap. A failure to adhere to this warning can cause

personal injury.

To change motor speed taps, remove the motor tap lead (See

Table 5.) and relocate it on the desired terminal on the plug-

Table 5—Speed Selector

'

Speed

Tap No.*

Common

C

Hi

1

Med-Hi

2

Med-Low

3

Low

4

*White wire from control box to common; black wire from control box to

cooling speed selection; red wire from control box to heating speed

selection.