A caution, A warning – Carrier 58DX User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

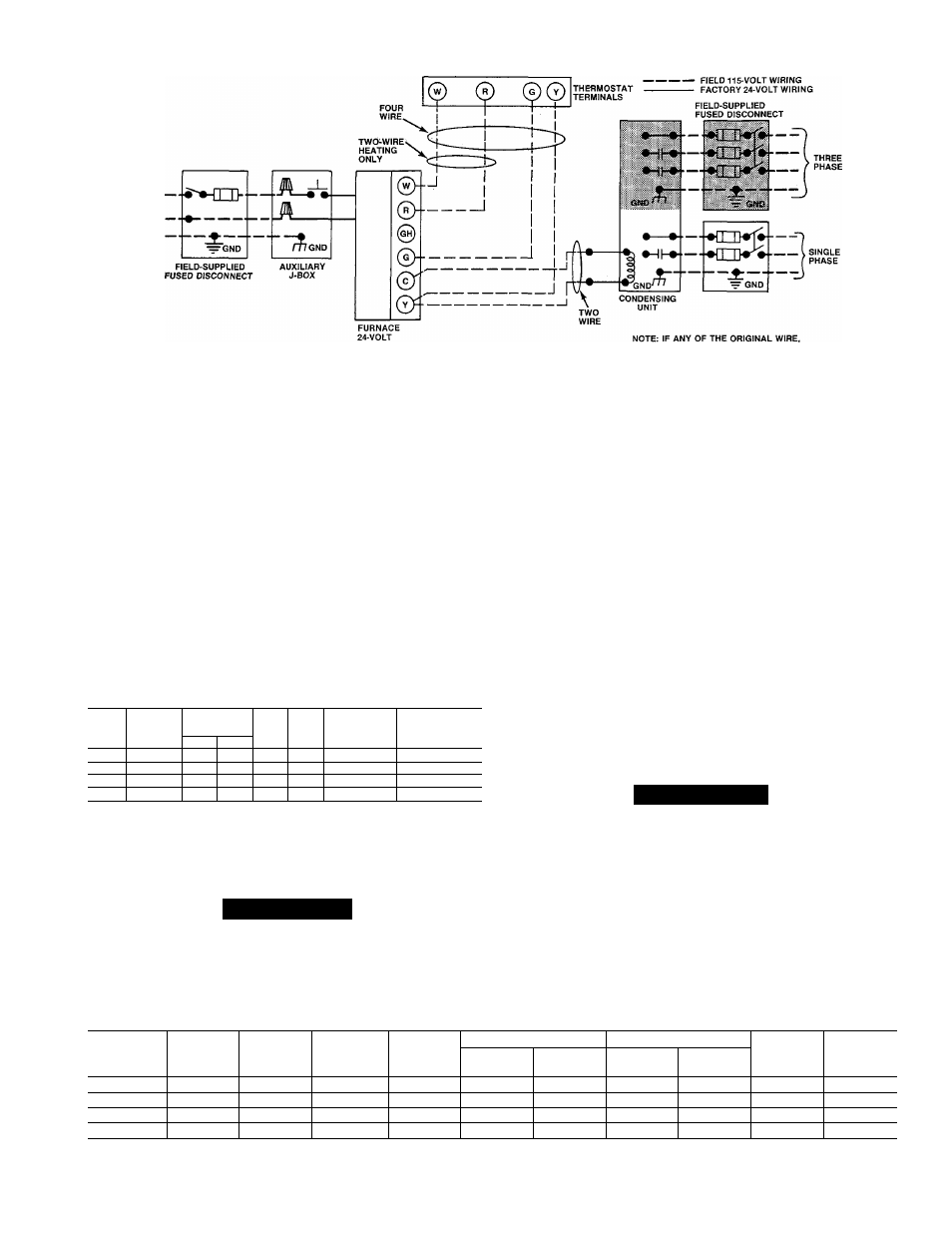

------------------ FIELD 24-VOLT WIRING

TERMINAL BLOCK

AS SUPPLIED, MUST BE REPLACED, USE

SAME TYPE OR EQUIVALENT WIRE.

A87502

Fig. 6—Heating and Cooiing Application Wiring Diagram

3. Assemble and install downflow subbase per instruc

tions packaged with subbase.

4. When completed, downflow subbase, plenum, and fur

nace (or coil casing when used) should be installed as

shown in Fig. 4.

VII.

ELECTRICAL CONNECTIONS

A. 115-Volt Wiring

iM PORT ANT:

Before proceeding with the electrical connec

tions, make certain that voltage, frequency, and phase cor

respond to that specified on the unit rating plate and Table

3. Also, check to be sure that the service provided by the

utility is sufficient to handle the load imposed by this equip

ment. Refer to Table 3 for the equipment electrical

specifications.

Table 3—Electrical Data

Volts-

Operating

Max.

Min.

Max. Wire

Max. Fusef or

SIZE

Hertz-

Voltage Range

Unit

Wire

Length

HACR-Type

Phase

Max*

Min*

Amps

Size

Feett

Ckt Bkr Amps

040

115—60—1

127

104

8.7

14

41

15

060

115—60—1

127

104

8.2

14

42

15

080

115—60—1

127

104

10.1

14

36

15

100

115—60—1

127

104

13.6

12

42

20

»Permissible limits of the voltage range at which the unit will operate sat

isfactorily.

fTime-delay fuse is recommended.

^Length shown is as measured one way along wire path between unit

and service panel for maximum 2% voltage drop.

A CAUTION

Do not connect aluminum wire between the disconnect

switch and the furnace.

See Fig. 6 for a wiring diagram showing the proper field

115- and 24-volt wiring. Be sure field wiring complies with

the National Electric Code and any local codes or ordnances

that may apply. Voltage to the furnace must be within the

limits shown in Table 3. Contact your local power company

for correction of improper voltage.

NOTE;

Operation of unit on improper line voltage consti

tutes abuse and could affect unit reliability. Do not install

the furnace in a system where voltage may fluctuate above

or below permissible limits.

Use a separate fused branch electrical circuit containing the

properly sized time-delay fuse or HACR-type circuit breaker

for this furnace. See Table 3 for fuse and wire specifications.

A disconnecting means must be located within sight of, and

readily accessible to, the furnace. The blower door switch

may be acceptable in some areas as a disconnecting means.

Line voltage must enter the auxiliary J-box on the right-

hand side of the furnace.

A WARNING

The cabinet must have an uninterrupted or unbroken

ground according to National Electrical Code. ANSI/

NFPA 70-1987, or local codes to minimize personal

injury if an electrical fault should occur. This may con

sist of electrical wire or conduit approved for electrical

ground when installed in accordance with existing elec

trical codes. Do not use gas piping as an electrical

ground. A failure to adhere to this warning can result in

an electrical shock, fire, or death.

Table 4—Ratings and Performance

SIZE

input

Btuh*

Indoor

Capacity

Btuht

ICS»*

Capacity

Btuht

Temperature

Rise

Range

Heating

Cooling

Motor

HP & Type

Approx

Shipping

Weight

Ext Static

Pressure

Cfm

Ext Static

Pressure

Cfm

040

44,000

40,000

40,000

20—50

0.10

1335

0.5

1265

1/3 PSC

179

060

66,000

60,000

60,000

40—70

0.12

1275

0.5

1170

1/3 PSC

187

080

88,000

81,000

80,000

40—70

0.15

1590

0.5

1565

1/2 PSC

202

100

110,000

101,000

100,000

40—70

0.20

2000

0.5

2035

3/4 PSC

241

*Gas input ratings are certified for elevations to 2000 ft. For elevations above 2000 feet, reduce ratings 4% for each 1000 ft above sea level.

tDetermined by U.S. Government tests.

»»Isolated combustion system; GAMA non-weatherized.