A caution, A warning, Fig. 9—location of coii area- not to be drilied – Carrier 50NQ User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

drain tube downward at a slope of at least 1 in, in every 10

ft of horizontal run. Be sure to check the dreun tube for

leaks.

Condensate water can be drained directly onto the roof in

rooftop installations (where permitted) or onto a gravel

apron in ground-level instaJlations. When using a gravel

apron, make sure it slopes away from the unit.

Step 3—Duct Connections

Model 50NQ has duct flemges on the supply and return mr

openings on the side and bottom of the unit except on sizes

048 and 060. 048 and 060 sizes do not have flanges on side

dischetrge openings. See Figs. 2 and 3 for connection sizes

and locations.

NOTE;

The design and insteJlation of the duct system must

be in accordance with the standards of the National Fire

Protection Association for installation of nonresidence-type

air conditioning and ventilating systems, NFPA No. 90A or

residence type, NFPA No. 90B, and/or loced codes and

ordinances.

Adhere to the following criteria when selecting, sizing, and

installing the duct system:

1. Remove appropriate panels from unit to obtain either

horizontal or down discharge. If models 018 through

042 are installed in horizontal discharge applications,

remove side duct covers, save screws, and instedl the

covers on bottom duct openings. To install duct covers

on bottom duct openings, remove one flange which

interferes with heater mounting plate. For models 048

through 060 remove either side or bottom duct covers

as needed and discard.

2. Select and size ductwork, supply-air registers, and

return-air grilles according to ASHRAE recom

mendations. Refer to Tables 2 & 3 for static pressure

capability.

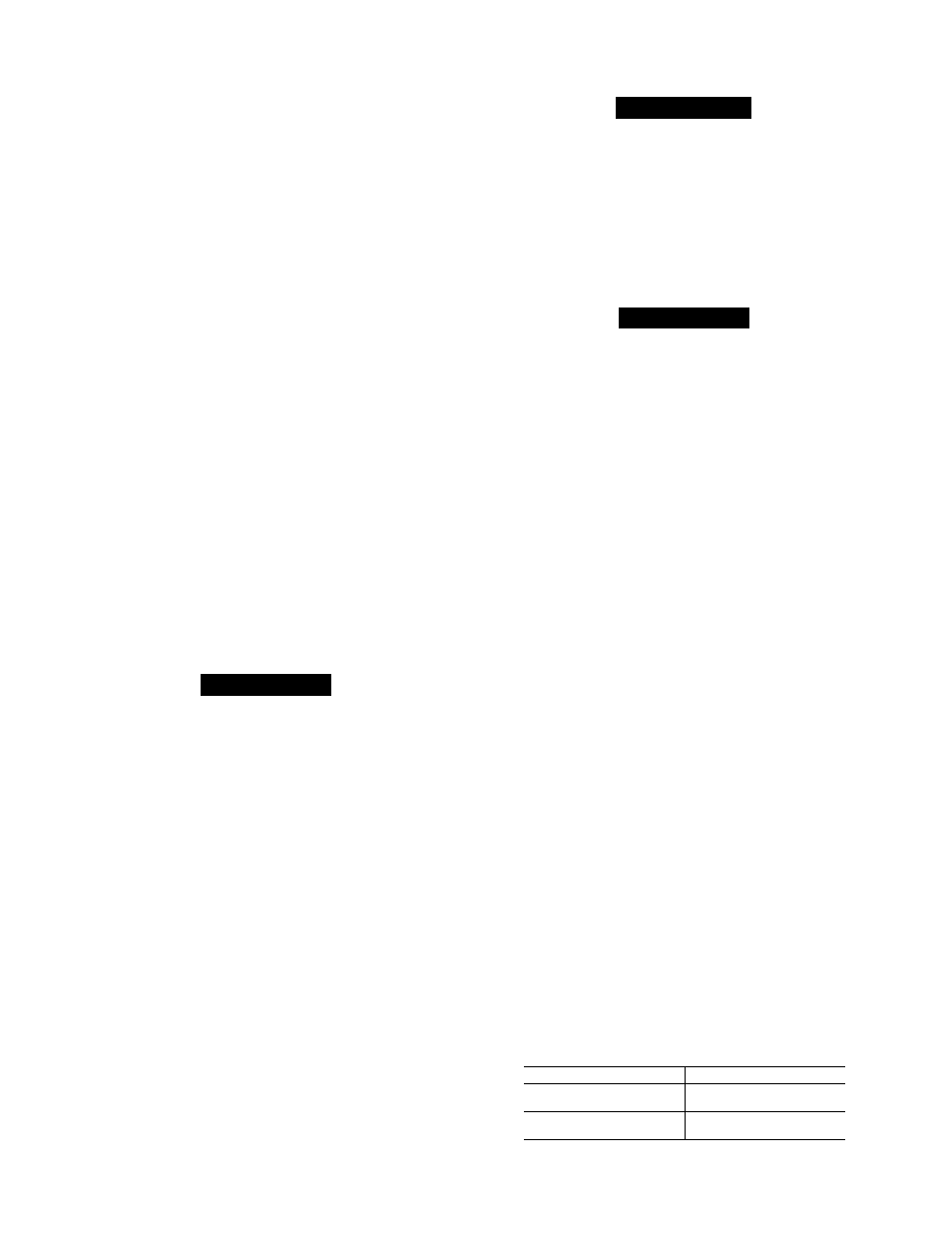

A CAUTION

When the duct-system fastening holes are being drilled

into side of unit instead of the unit duct flanges, use

extreme care to avoid puncturing the coil or coil tubes.

See Fig. 9.

5.

6

.

3. Use flexible transition between rigid ductwork and unit

to prevent transmission of vibration. The transition

may be screwed or bolted to duct flemges. Use suitable

gaskets to ensure weather and edrtight seed.

«

4. Install external, field-supplied air filter(s) in return-air*

ductwork where it is easily accessible for service. Rec

ommended filter sizes are shown in Table 4.

Size all ductwork for maximum required airflow (either

heating or cooling) for unit being installed. Avoid

abrupt duct size increases or decreases.

Adequately insulate and weatherproof all ductwork

located outdoors. Insulate ducts passing through

unconditioned space and use vapor barrier in accor

dance with latest issue of SMACNA and ACCA mini

mum installation standards for heating and air condi

tioning systems. Secure edl ducts to building structure.

Flash, weatherproof, and vibration-isolate £dl openings

in building structure in accordance with local codes and

good building practices.

For

Canadian

Installations

Only—An

L-shaped

exhaust duct fabricated of sheet metal or a material

rated 94-5V shall be used in the case of downflow

applications.

7.

8.

Step 4—Electricial Connections

A WARNING

The unit cabinet must have an uninterrupted, unbro

ken, electrical ground to minimize the possibility of per

sonal injury if an electriced fault should occur. This

ground may consist of electrical wire connected to the

unit ground lug in the control compartment, or conduit

approved for electriced ground when instedled in accor

dance with the National Electrical Code ANSI/NFPA-

70 (in Canada, Canadian Electrical Code CSA C22.1)

and loced electriceil codes.

A CAUTION

A failure to follow these precautions could result in

damage to the unit being installed:

1. Meike all electrical connections in accordance with the

latest National Electrical Code, ANSI/NFPA-70 and

local electrical codes governing such wiring. In Canada,

all electrical connections must be in accordance with

CSA standead C22.1 Canadian Electrical Code part 1

and applicable local codes. Refer to Unit Wiring

Diagram.

2. Use only copper conductor for connections between

field-supplied electrical disconnect switch and unit. DO

NOT USE ALUMINUM WIRE.

3. Ensure that high-voltage power to unit is within oper

ating voltage range indicated on unit rating plate (Fig.

4). On 3-phase units, ensure that phases are voltage

and current balanced. Consult local power company for

correction of improper voltage and/or phase balance.

4. Insulate low-voltage wires for highest voltage con

tained within conduit when low-voltage control wires

are run in same conduit as high-voltage wires.

5. Do not damage internal components when drilling

through any panel to mount electriceil hardware, con

duit, etc.

CAUTION: DO NOT DRILL

OR SCREW IN SHADED AREA

5 0"-

O

SUPPLY

RETURN

INLET/OUTLET PANEL

Cabinet Size

A

Smaii Cabinet

20-1/2"

018-042

Large Cabinet

21-1/4"

048-060

Fig. 9—Location of Coii Area-

Not to be Drilied