14 f, Oversizing chillers, Multiple chillers – Carrier 30GB060 User Manual

Page 5: Electrical/utility interests, Application data (cont)

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

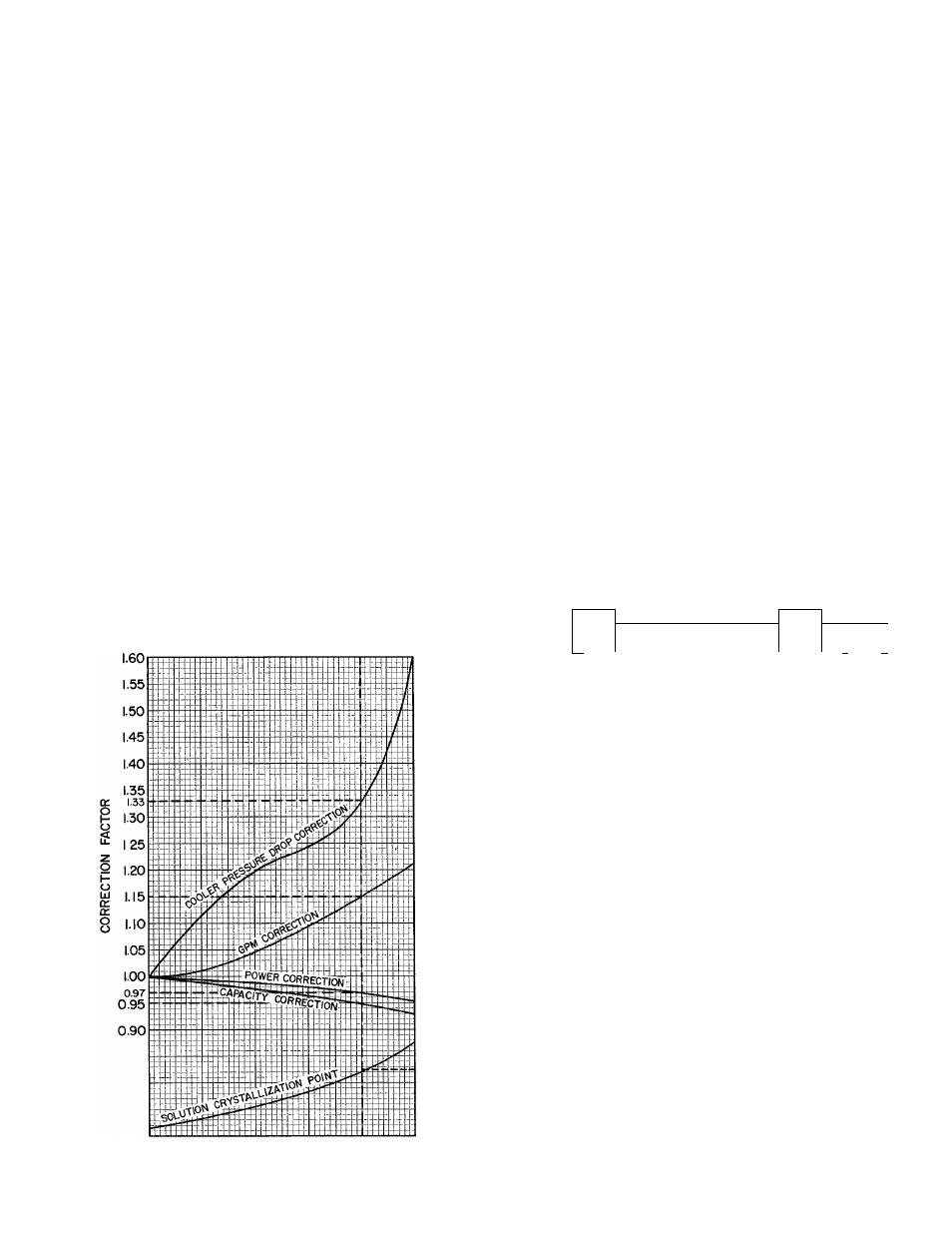

Correct unit capacity — On glycol performance

capacity correction curve, read 0.95.

Corrected capacity = 0.95 x determined capacity

- 0.95 X 61.3

= 58.2 tons

Correct chilled water flow — On the gpm correction

factor curve, read 1.15.

Chilled water flow (at corrected capacity)

24 X corrected capacity

Application data (cont)

temperature rise

24 X 58.2 tons

= U.S. gpm

14 F

99.8 U.S. gpm

Chilled water flow (40% solution) = 1.15x99.8

= 114.7 U.S. gpm

Correct cooler pressure drop — On cooler pressure

drop correction curve, read 1.33.

On cooler pressure drop curve, for 114.7 gpm, read

PD = 10 ft water gage. The pressure drop for 40% solution =

1.33 X 10.0 = 13.3 ft water.

Correct compressor power input (kW) — On power

correction curve, read 0.97 correction factor at 40%

EG concentration.

Power input from Selection Procedure example

= 71.1 kW.

Corrected power input = 0.97 x 71.1 = 68.9 kW.

ETHYLENE GLYCOL PERFORMANCE

CORRECTION FACTORS AND SOLUTION

CRYSTALLIZATION POINTS

10

20

30

40

% CONCENTRATION (BY WEIGHT)

ETHYLENE GLYCOL

50

(F)

-40

-20

-10

0

+20

40

(C)

r-40

c -30

-20

-10

0

Oversizing chillers

Oversizing chillers by more than 15% at design conditions

must be avoided as the system operating efficiency would

be affected adversely (resulting in greater/excessive

electrical demand). When future expansion of equipment

is anticipated, it is strongly recommended that a single

chiller be installed to meet present load requirements

and a second chiller added to meet the additional load

demand.

It is also recommended that the installation of 2 smaller

chillers be considered where operation at minimum load

is critical. The operation of a smaller chiller loaded to a

greater percent of minimum is preferred to operating a

single chiller at or near its minimum recommended value.

Multiple chillers

Where chiller capacities greater than 200 tons (703 kW)

are required, or where stand-by capability is desired,

chillers may be installed in parallel. Units should be of

equal size to ensure balanced water flows. Where a large

temperature drop (>25F [13.9 C]) is desired, chillers

may be installed in series. Water temperature sensors

need not be moved for multiple chiller operation. A 10-ft

(3-m) separation is required between units for airflow,

and a 6-ft (1.8-m) distance is required from units to

obstructions. See figure. See Physical Data for service

clearances.

(3m)

(I.Sm)

10 FT

6

FT

* MINIMUM

MINIMUM

/

/

/

/

/

/

/

/

MULTIPLE UNIT SEPARATION

Electrical/utility interests

Energy management — See 30GB Controls and Trouble

shooting manual and accessory installation instructions

for details.

Demand limiting (also called load shedding) — When

utilities demand for electricity exceeds a certain level,

loads are shed to keep electricity demand below a pre

scribed maximum level. Typically, this happens on hot

days when air conditioning is most needed.

Load shedding must be done intelligently. Demand

may be limited on Model 30GB by resetting water tem

perature, or by using a demand limit accessory that

unloads the chiller to a given predetermined percent of

the load. Both features require signal from an intelligent

central control. Do not cycle demand limiter for less than

10 minutes on and 5 minutes off.

Duty cycling cycles electrical loads at regular intervals

regardless of need. This reduces electrical operating

costs of a building by “fooling” demand indicating

devices. Duty cycling of compressors or fans is not

recommended since motor winding and bearing life

suffer from constant cycling.