Condenser, Low-ambient operation, A warning – Carrier 30GB060 User Manual

Page 4: Capacity correction (antifreeze), Application data (cont)

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Application data (cont)

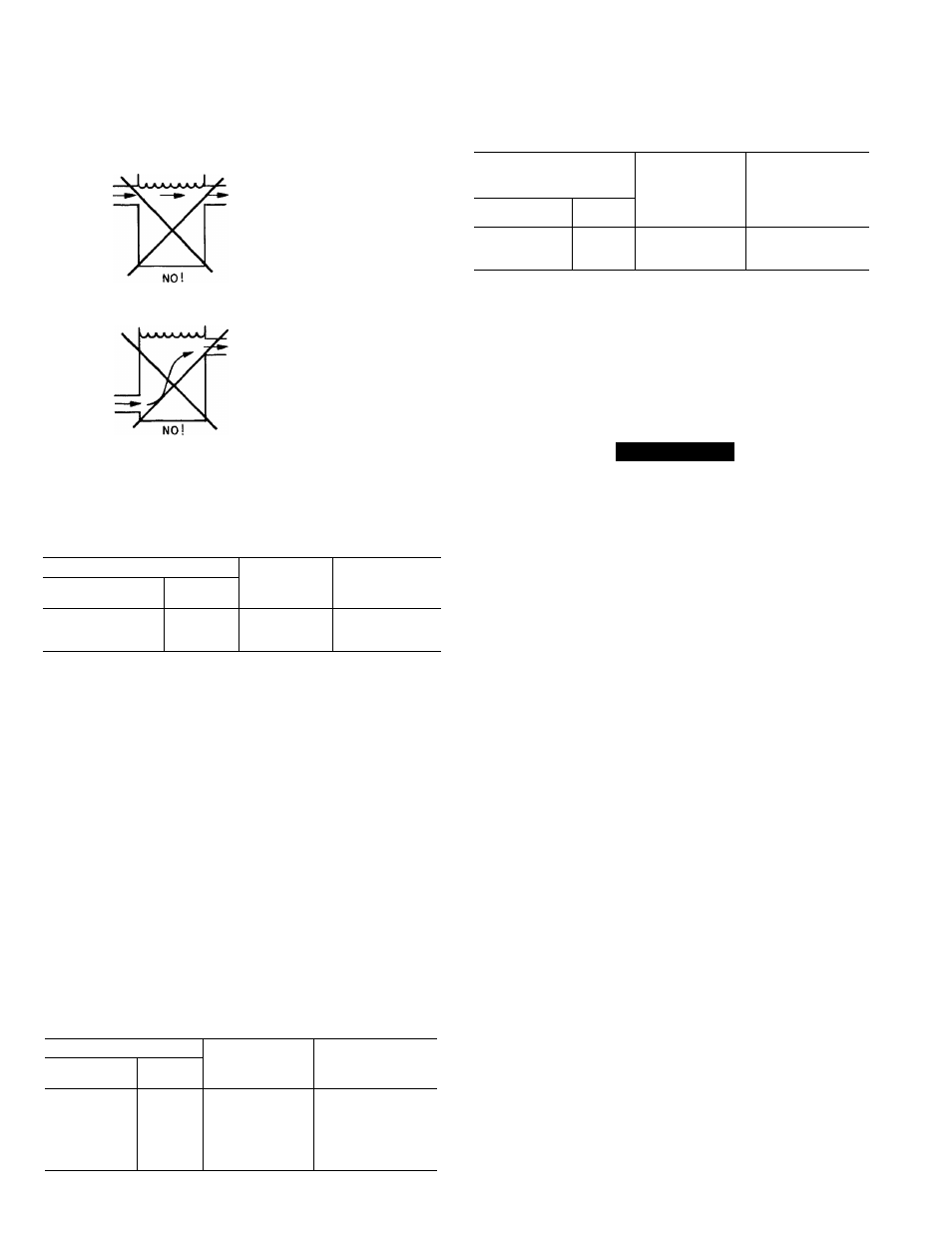

per ton (6.5 to 10.8 liters per kW). To achieve this volume,

it is often necessary to install a tank in the loop. Tank

should be baffled to insure that there is no stratification

and that water (or brine) entering tank is adequately mixed

with liquid in the tank.

GOOD

GOOD

Cooler fouling factor used to calculate tabulated ratings

was 0.0005 ft2. hr. °F/Btu (0.000088 m^. K/W). As fouling

factor is increased, both unit capacity and compressor

power decrease. Standard ratings should be corrected

using following multipliers:

FOULING FACTOR

CAPACITY

MULTIPLIER

COMPRESSOR

POWER

MULTIPLIER

ENGLISH

((F . hr. °F/Btu)

SI

(m*. K/W)

0.0005

0.000088

1.00

1

00

0.001

0.000176

0.97

0.98

0.002

0.000352

0.91

0.91

Cooler protection in form of ethylene glycol (or other

suitable brine) is recommended when operating in areas

which experience temperatures below 32 F (0°C) to

protect cooler should there be a loss of cooler heater

power. Even though unit cooler is protected with insula

tion and an electric heater that protects the cooler down

to 10 F (-12 C), it does not protect water piping external

to unit. Use only antifreeze solutions approved for heat

exchanger duty. Use of automotive antifreezes is not

recommended because of the fouling that can occur once

their relatively short-lived inhibitor breaks down.

Draining cooler and outdoor piping is recommended if

system is not to be used during freezing weather condi

tions. See section below for low-ambient operation.

Condenser

Altitude correction factors must be applied to standard

ratings at altitudes above 2000 ft (610m) using following

multipliers:

ALTITUDE

CAPACITY

MULTIPLIER

COMPRESSOR

POWER

MULTIPLIER

ENGLISH

(ft)

SI

(m)

0

0

1

00

1.00

2000

610

0 99

1.01

4000

1220

0 98

1.02

6000

1830

0,97

1.03

8000

2440

0.96

1.04

10000

3050

0.95

1.05

Condenser airflow restrictions will affect the unit

capacity, condenser head pressure and compressor

power input. Correction factors to be applied for external

static restrictions up to 0.2 in. wg (50 Pa) are shown below.

EXTERNAL

STATIC

RESISTANCE

CAPACITY

MULTIPLIER

COMPRESSOR

POWER

MULTIPLIER

ENGLISH

(in. wg)

SI

(Pa)

0.0

0.0

1

00

1.00

0.1

25

0 986

1

01

0.2

50

0 968

1.03

High-ambient temperature — Standard 30GB chillers

can operate to 115 F (46 C) ambient temperature.

Low-ambient operation

Flotronic^“ 30GB chillers with electronic expansion valves

(EXV) will start and operate at ambients down to 0°F

(-18 C) with following field provisions:

Wind baffles must be added for operation below 32 F (0°C).

A WARNING

Operation at low ambient is not recommended if

minimum load on chiller is below minimum step of

unloading.

Protection against freeze-up — It is recommended

that field-installed chilled water piping be protected at

lower ambient temperatures by wrapping with field-supplied

heating cable and covering with 2-in. (50-mm) thick closed

cell insulation.

Antifreeze solution must be added to water loop to

protect loop down to 15 F (8 C) below minimum operating

ambient temperature.

For operation of EXV-equipped chillers below 0°F

(-18 C) and for operation of TXV-equipped (factory-

installed option) chillers below 32 F (0°C), down to -20 F

(-29 C), the Carrier Motormaster® condenser head pres

sure control and its associated components must be

added. Consult your local Carrier representative for

complete details.

Provide sufficient volume in the chilled water loop — At

least 6 gallons per ton of refrigerant (6.5 liters per kilowatt)

is recommended minimum, provided there is a moderate

system load.

Capacity Correction (Antifreeze)

Ethylene glycol (or other suitable brine) should be used in

installations where subfreezing temperatures are ex

pected. Unit performance data must be corrected for

the addition of ethylene glycol as shown in following

example. Correction factors may be derived from follow

ing curves.

Example: Where a 5 F outdoor temperature is anticipated,

determine concentration of ethylene glycol to protect

system to -10 F ambient temperature at zero flow.

Enter the solution crystallization point curve at -10 F,

read 40% concentration of ethylene glycol is required to

prevent crystals from forming in solution.

Consider the 30GB060 unit from the Selection Pro

cedure (Water) example (refer to correction curves at

40% solution).