Application data (cont), Leaving water temperature reset, Cooler flow range – Carrier 30GB060 User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Application data (cont)

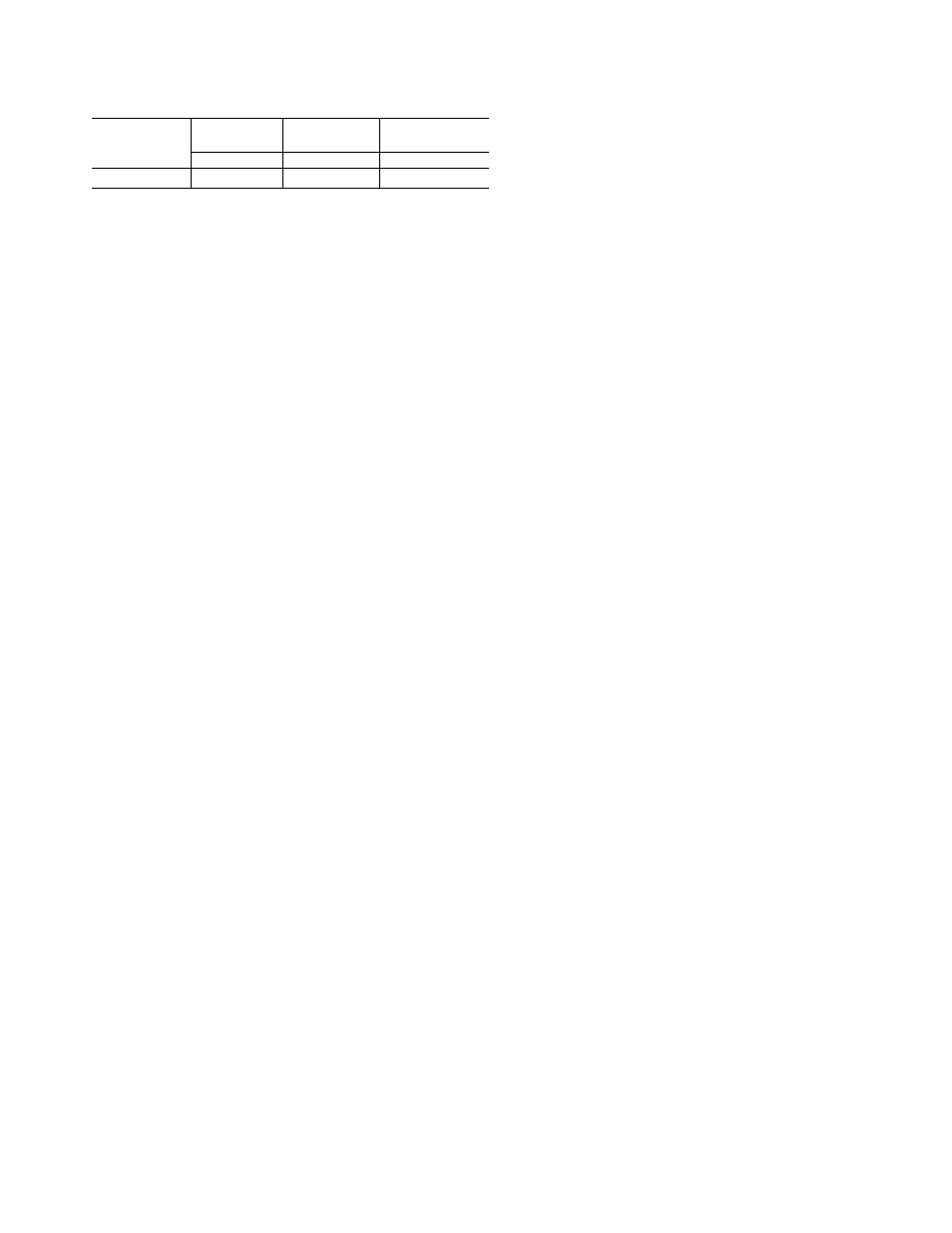

MINIMUM COOLER WATER FLOW RATES

AND MINIMUM LOOP VOLUME

MINIMUM

PRESSURE

MINIMUM

UNIT 30GB

FLOW (1)

DROP

VOLUME (2)

Gpm

ft of water

Gallons

060

67

3.8

180

NOTES.

1

. Minimum flow based on 1 5 fps veiocity in cooier without special

cooler baffling

2. Minimum Loop Volumes:

Gallons = V

X

ARl Cap (tons)

APPLICATION

Normal Air Conditioning

Process Type Cooling

Low Ambient Unit Operation

Leaving water temperature reset

Accessory board* may be installed in 30GB chillers to

provide reset of LCWT in constant water flow systems.

Reset reduces compressor power usage at part load when

design LCWT is not necessary. Humidity control should

be considered since higher coil temperatures resulting

from reset will reduce latent heat capacity. Three reset

options are offered;

From return water temperature*

— Increases LCWT

temperature set point as return (or entering) water tem

perature decreases (indicating load decrease). Option

may be used in any application where return water provides

accurate load indication. Limitation of return water reset is:

LCWT may only be reset to value of design return water

temperature. Return reset is the simplest of 3 reset acces

sories available, as return water sensor is already installed.

From outdoor temperature*

— Increases LCWT as

outdoor ambient temperature decreases (indicating load

decrease). This reset should be applied only where outdoor

ambient is an accurate indication of load. An accessory

thermistor is required.

From space temperature*

— Increases LCWT as space

temperature decreases (indicating load decrease). This

reset should be applied only where space temperature is

an accurate indication of load.

For details on applying a reset option, refer to 30GB

Controls and Troubleshooting Instructions.

*Obtain ordering part numbers from current price pages.

Cooler flow range

Ratings and performance data in this publication are

for a cooling range of 10°F or 6°C. Flotronic^" chillers with

microprocessor control may be operated at a different

temperature range provided flow limits are not exceeded.

For minimum flow rates, see Table. High flow rate is limited

by pressure drop that can be tolerated. If another range is

used, apply LCWT correction as given in selection example.

Minimum cooler flow

(maximum cooler temperature

range) for standard units is shown in Table. When gpm

(L/s) required is lower (or range higher), follow recom

mendations below:

a. Multiple smaller chillers may be applied in series, each

providing a portion of the design temperature range.

b. Cooler water may be recirculated to raise flow rate.

However, mixed temperature entering cooler must

be maintained a minimum of at least 5°F (2.8°C) above

the leaving chilled water temperature.

c. Special cooler baffling is required to allow minimum

flow rate to be reduced 12%.

CHILLER COOLER

RECIRCULATION

SUPPLY

RETURN

Maximum cooler flow

(> 5 gpm/ton or < 5 F range

[>0.09 L/s . kW or <2.7 C range]) results in practical

maximum pressure drop through cooler.

a. Return water may bypass the cooler to keep pressure

drop through cooler within acceptable limits. This

permits a higher AT with lower water flow through

cooler and mixing after the cooler.

b. Special cooler baffling is available by special order,

to permit a cooler flow rate increase of 10%.

CHILLER COOLER

BYPASS

SUPPLY

RETURN

Variable cooler flow rates

may be applied to a standard

30GB chiller. Unit will, however, attempt to maintain a

constant leaving chilled water temperature. In such cases,

minimum flow must be in excess of minimum flow given in

Table and flow rate must change in steps of less than 10%

per minute. Apply 6 gallons per ton (6.5 liters per kW) water

loop volume minimum if flow rate changes more rapidly.

Water loop volume

— In circulation must equal or

exceed 3 gallons (11.4 liters) per nominal ton of cooling

(3.25 liters per kW) for temperature stability and accuracy

in normal air conditioning applications. (For example, a

30GB060 would require 180 gallons in circulation in system

loop — see Table.) For process jobs where accuracy is

vital or for operation at ambient below 32 F (0°C) with low

unit loading conditions, there should be from 6 to 10 gallons