Carrier 16JB User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

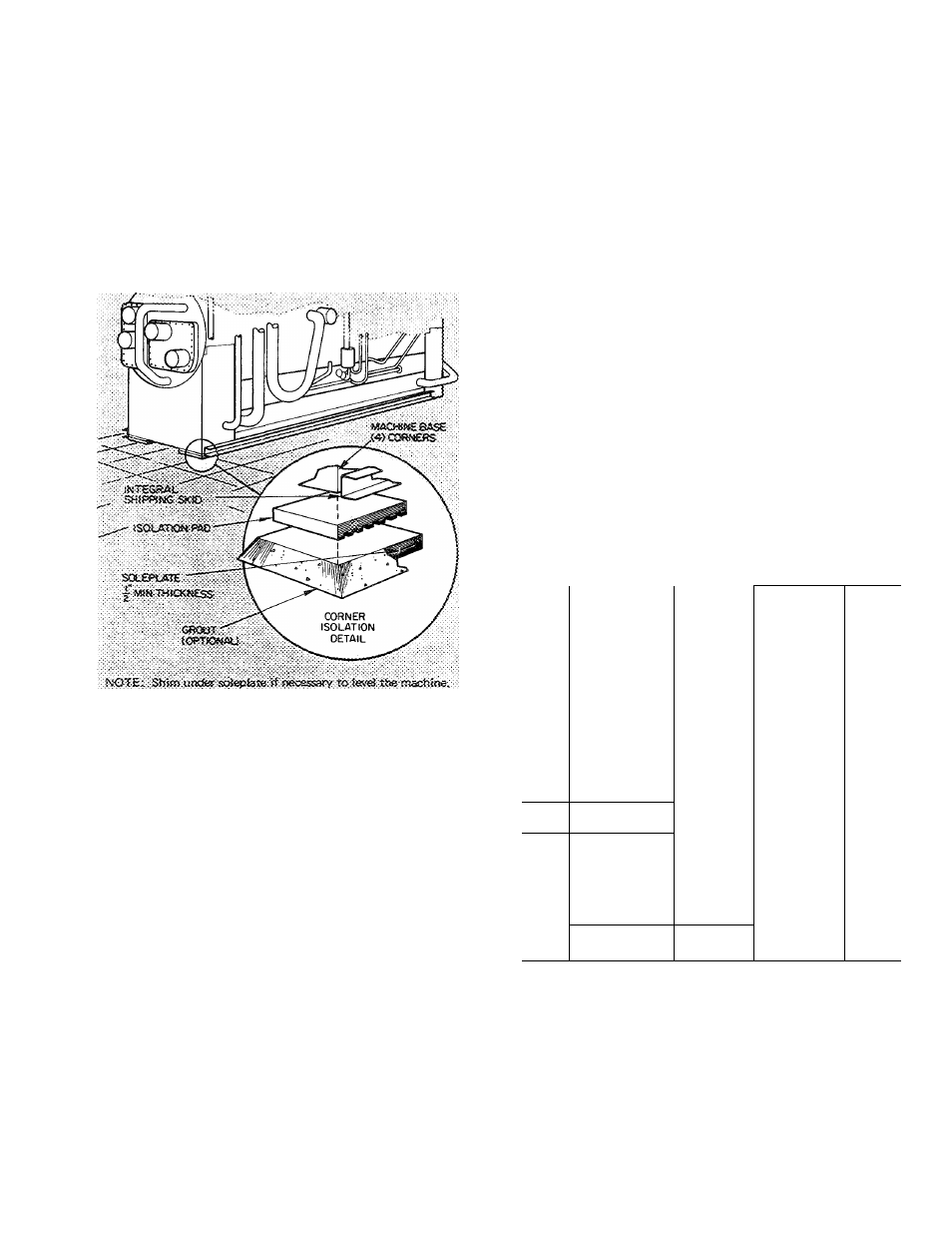

The integral shipping skids, or base rails, are

normally left on the machine. However, the base

rails may be removed, if desired, but not until the

machine is in final position. When isolation pads

are used, they should be located under the corners

of the machine, atop soleplates with 1/2-in. min

imum thickness (see Fig. 10). The soleplate ensures

machine contact on the floor only at the corners

when base rails are left on. Shims may be inserted

under the soleplates for leveling the machine.

Grouting is optional.

Fig. 10 — Typical isolation Assembly

Explosionproof Machines

— 16JB standard absorp

tion machines can be factory equipped with

explosionproof

electric

motors

and

controls

suitable for Class 1, Group D hazardous locations

specified by the National Electrical Code. Modi

fications to the standard control system are

described in the controls application publications.

Outdoor Installation

— Outdoor installation of the

16JB absorption machine creates a number of

special problems which must be resolved. Such

applications should be considered only when the

customer

has

qualified

operating

personnel,

familiar with the maintenance of mechanical equip

ment located outdoors. Standard machines require

protection

from

weather.

A

simple,

heated

structure is preferred. If this is not possible,

protection from the weather must be provided by

machine modifications.

WEATHERPROOFING -- Pneumatic control sys

tems are recommended for outdoor installations.

Controls can be factory furnished to meet NEMA

No. 4 Waterproofing Specifications.

FREEZE PROTECTION — When the machine area

may be subjected to temperatures below 40 F and

if the machine is to be shut down for an extended

time during these low-temperature periods, all

water circuits and tube bundles should be drained,

then filled with ethylene glycol. Table 5 lists

storage volumes of 16JB header and tube bundles.

This data can be used when calculating the

quantity of ethylene glycol needed to provide

adequate freeze protection.

Table 5

Header and Tube Bundle Storage

Volumes (gal.)

UNIT

16JB

EVAPORATOR

ABSORBER

CONDENSER

HOT

WATER

GEN

010

25

27

14

14

012

28

30

16

16

014

30

35

17

17

018

43

46

24

23

021

48

51

26

25

024

57

62

32

30

028

64

69

36

34

032

76

83

42

39

036

83

90

46

43

041

96

104

52

49

047

106

117

59

56

054

057

108

150

57

74

061

068

129

179

68

87

077 ^

084

158

215

129

106

097

107

198

271

163

138

115

124

228

310

186

150

GEN — Generator