Fig. 9 — machine hot surfaces – Carrier 16JB User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

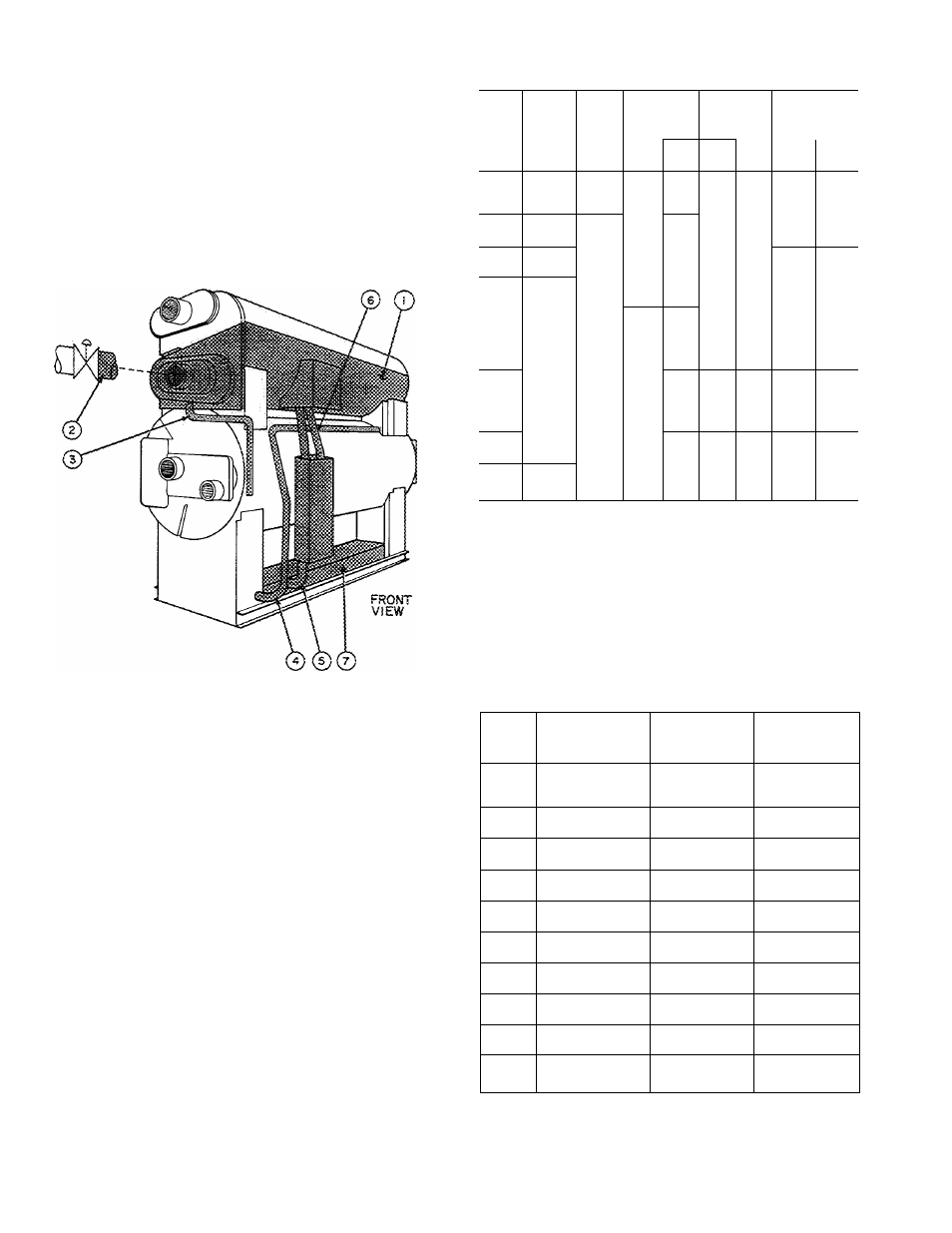

The generator shell and some of the machine

piping will become hot during operation. If insula

tion is to be used as a safety precaution, or to

reduce ambient temperature in the machine room,

we recommend insulating the surfaces shown in

Fig. 9. Hot-surface dimensions are given in Table 3.

Generator insulation can be either blanket-type

or low-pressure boiler insulation. Insulation used

for piping is generally standard low-pressure steam

pipe insulation.

Table 3 — Insulation For Hot Surfaces*

HOT SURFACES THAT

CAN BE INSULATED

LEGEND

1 — Generator Shell (refer to Table 4 for sq ft surface area)

2 — Steam Supply Line

3 — Condensate Line

4 — Weak Solution Line (to generator)

5 — Strong Solution Line (from generator)

6 — Generator Overfiow Tube (only hot during abnormal

conditions)

7 — Heat Exchanger

Fig. 9 — Machine Hot Surfaces

isolation

— 16JB machines are not in themselves a

major source of vibration ; and isolation equipment

is not supplied with the machine unless requested

on the order. It is possible, however, for a machine

to receive and transmit vibrations from other

sources that are imperfectly isolated such as

condensing water pumps, chilled water pumps, or

other piping. Isolation packages are available from

a number of manufacturers. Specifications for

Carrier machines are given in Table 4.

UNIT

16JB

GENt

SHELL

HT

EXCH

STRONG

SOL LINE

WEAK

SOL LINE

GEN

OVERFLOW

(GO) TUBE

(ft 2)

(ft 2)

Lgth

(ft)

Size

(in.)

Lgth

(ft)

Size

(in.)

Lgth

(ft)

Size

(in.)

010

012

014

62

40

7

3

20

V/2

1 1

3

018

021

67

45

7

3

21

2

12

4

024

028

72

50

8

4

22

2

13

4

032

036

77

55

9

4

23

2'/2

15

4

041

047

82

60

10

4

24

3

16

4

054

057

98

55

8

4

22

3

10

4

061

068

98

60

10

4

24

3

12

4

077

084

152

102

16

4

44

2

3

4

097

107

184

no

18

4

47

3

4

4

115

124

184

1 18

20

4

49

3

4

4

•Refer to Fig. 10 for location of hot surfaces.

fl nciudes outiet box and ends

GEN

—Generator

HT EXCH

— Heat Exchanger

Table 4 — Isolation Pad and Soleplate

Specifications

UNIT

16JB

NO. (EACH)

OF PADS AND

SOLEPLATES

PAD

DIMENSIONS

(in.)

SOLEPLATE

DIMENSIONS

(in.)

010

012

014

4

9 X

6

X

%

10 X

7

X

V

2

018

021

4

9 X 10 X

%

10 X 11

X V

2

024

028

4

9 X 12 X Vs

10

X 13 X

%

032

036

4

9 X 14 X %

10 X 1 5 X

(4

041

047

4

9 X 18 X %

10 X 19 X

%

054

057

4

12 X 18 X Vs

13 X 19 X

%

061

068

4

14 X 18 X %

15 X 19 X h

077

084

6

12 X 18 X

%

13 X 19 X

%

097

107

6

15 X 18 X Vs

16 X 19 X

%

115

124

6

16 X 18 X %

17 X 19 X

‘/2

NOTE:

Higher isolation efficiencies may be obtained with double-layer

pads. Double-layer pads, factory-fused together, are available from

various manufacturers. If two single-layer pads are used, a metal

divider equal to pad dimensions should be inserted between iayers.