Hot water machines, Fig. 5 — pneumatic control schematic, Piping for water temperature of 300 f or below – Carrier 16JB User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

#

into the vacuum pump condensate return system.

If this method is used, it is desirable to use either

cold boiler feed water or any other cold water

source which will benefit by heat rejected from hot

condensate.

CLOSED CONDENSATE RETURN

(PRESSURIZED)

SYSTEM

16JB010-068 — Many manufacturers have high-

temperature condensate units, generally suited for

use with most of the Carrier absorption machine

Une. Because the condensate units are usually quite

high, some of the smaller machines may not be

high enough to provide liquid head for gravity

flow. In these cases, the closed system should not

be used. A typical unit consists of a closed ASME

Code receiver and centrifugal pump for returning

hot condensate to the boiler. This system has the

advantage of complete condensate recovery with

out flash losses often experienced in atmospheric

return systems.

These systems require very careful application

to the absorption machine. There are two common

types of closed condensate systems :

The first type will operate under pressurized

conditions. The pressure between the generator

and receiver is equalized and condensate flows by

gravity to the closed receiver located below the

generator outlet. It is essential that under these

conditions the vacuum breaker on the 16JB

generator should be blocked. This is to prevent air

from building up in the closed receiver. Also, the

closed receiver should be equipped with a device

that is capable of releasing the air that is in the

system after a shutdown period. A thermostatic

vent is usually suppUed for this purpose. In this

type of system, the pumps on the receiver can

pump under vacuum.

The second type of closed system consists of a

closed

receiver

with

atmospheric

condensate

pumps. Therefore, the receiver is usually equalized

with the steam chest. In this type of system, the

vacuum breaker and the generator must be left open

so that the receiver cannot go into the vacuum range.

A steam trap is usually recommended.

16JB077-124 — Because the 16JB077-124 units

have two steam inlets, these machines must be

considered as having two generators when applying

a closed condensate system. Each end of the

machine operates at a different steam pressure.

This could cause the condensate to back up into

the generator and cause dangerous water hammer if

the condensate system were not properly designed.

Each end of the machine should be considered

similar to the system on 16JB010-068 units (see

Fig. 4).

CLOSED

CLOSED

CONDENSATE

CONDENSATE

RECEIVER

П r~

RECEIVER 1

TO lA S

1------------------------------------- 1

1 til TO

L-b^-eoa^

NOTE' Each J5IKÌ 5s similar t o O f ) l&lóOliKSeS machìnes.

Fig. 4 — Closed Condensate Return System

(16JB077-124)

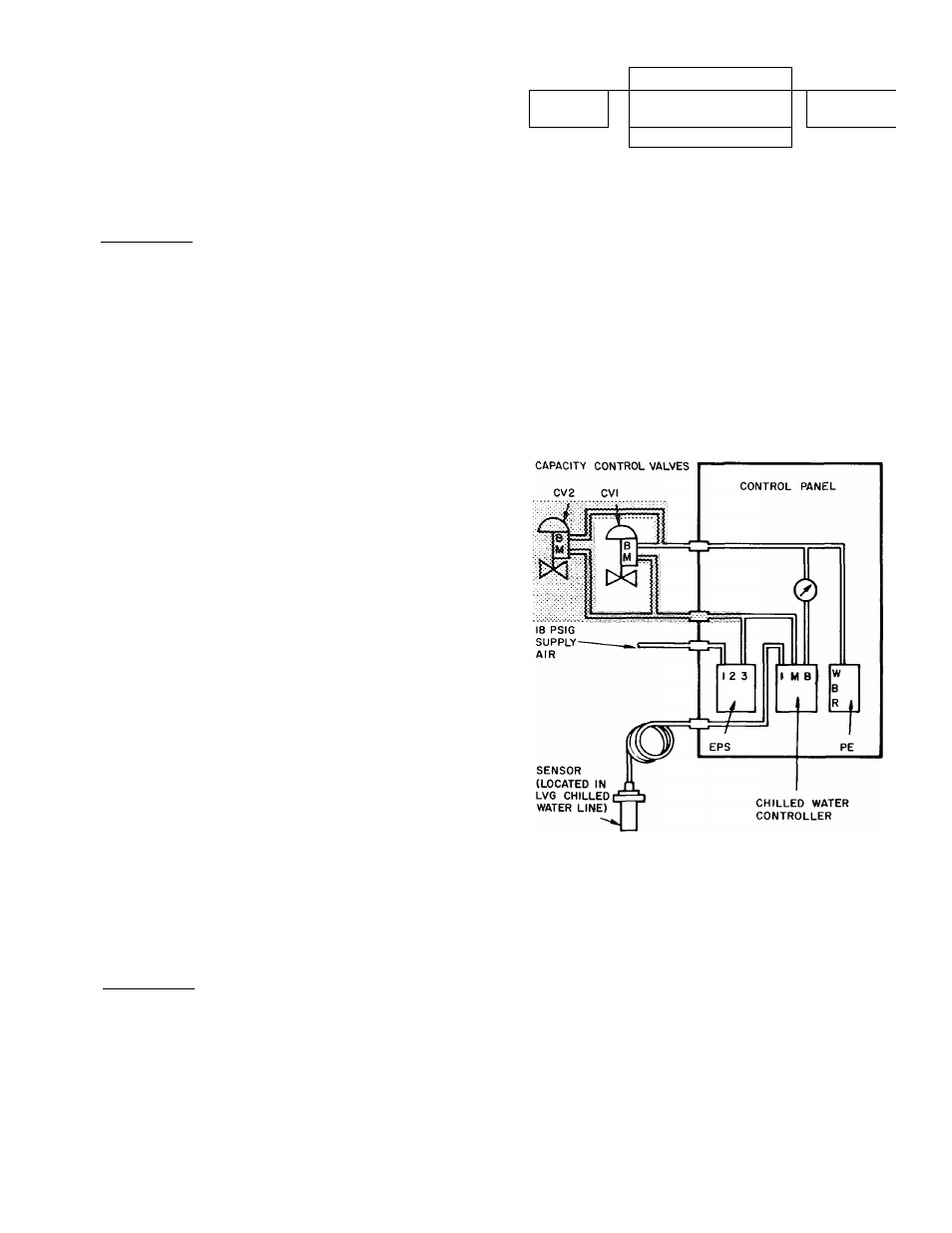

HOT WATER MACHINES

The 16JB hot water absorption machines are

furnished with pneumatic controls only. Fig. 5

schematically

illustrates

the

capacity

control

valves, controls and control panel. There are two

commonly used piping systems, depending on the

temperature of the supply hot water.

077 THRU 124 SIZES ONLY

EPS

— Electric-Pneumatic Switch

PE

— Pressure-Electric Switch

Fig. 5 — Pneumatic Control Schematic

Piping For Water Temperature of 300 F Or Below

— Fig. 6 gives suggested hot water piping when

supply hot water is 300 F or below. The capacity

of the machine is controlled by regulating the flow

of hot water through the generator. Either a

two-way or three-way capacity control valve (CV)

can be used. Machine sizes 16JB077-124 require

two capacity control valves if partial load effi

ciency of double generators is to be utilized.