Service, Component location – Carrier 50WQ User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

MODEL 50WQ

R-22

CHG (Ib-oz)'*

Refrig control

Diameter (in. Nom)

Width (in. Nom)

Range Cfm

Motor Hp

Motor Rpm (3 speed)

Water Flow Range

(Gpm)

014

1 5-5

SERVICE

Table 4 — Service Data

[’'"“

oil

1„...

... .... J..........

027

033

1-10 1

1-14 1

2-0

2-2

Capillary Tube

2-6

1075 Nominal

Tube-in-Tube; cupro nickel or copper

2-8

1

2.5-9

I

3-10

10

10

Centrifugal

10

— Direct Drive

10

10

7

7

7

7

7

400-600

500-700

600-800

750-1000

950-1200

1/8

1/8

1/6

1/6

1/4

0«

T-

1

r

11

7

1040-1375

1/3

4-12

t

"Factory refrigerant charge

Refrigerant Charging

— Unit refrigerant system

is factory charged. When recharging is necessary

during heating or cooling season, weigh in total

charge indicated in Table 4. Remove any refrigerant

remaining in system before recharging. If system has

lost complete charge, evacuate system to 500

microns (29.7 in. vacuum) before recharging.

Service port connections are provided on high and

low sides of refrigerant system for evacuation and

charging. (See Fig. 4 for service port location.)

Dial-a-charge charging cylinder is an accurate

device used to recharge systems by weight. These

cylinders are available at refrigeration supply firms.

To check and/or adjust refrigerant charge during

cooling season, use correct cooling cycle charging

chart (Fig. 6, 8, 10, 12, 14, 16) or Carrier Charge-

master® charging device (Carrier Part No.

38GC680004). Charging charts or Chargemaster

may also be used as alternate methods of recharging

system. Charging methods are described below.

To check

system operation

during heating cycle,

use correct Heating Cycle Operation Check Chart

(Fig. 7, 9, 11, 13, 15, 17). These charts indicate

whether a correct relationship exists between unit

operating pressures and water temperature leaving

heat exchanger. If pressure and water temperature

lines do not intersect on chart, the system refrigerant

charge may not be correct or other system abnor

malities may exist. Do not use Operation Check

Charts to adjust refrigerant charge. Weigh charge

into system.

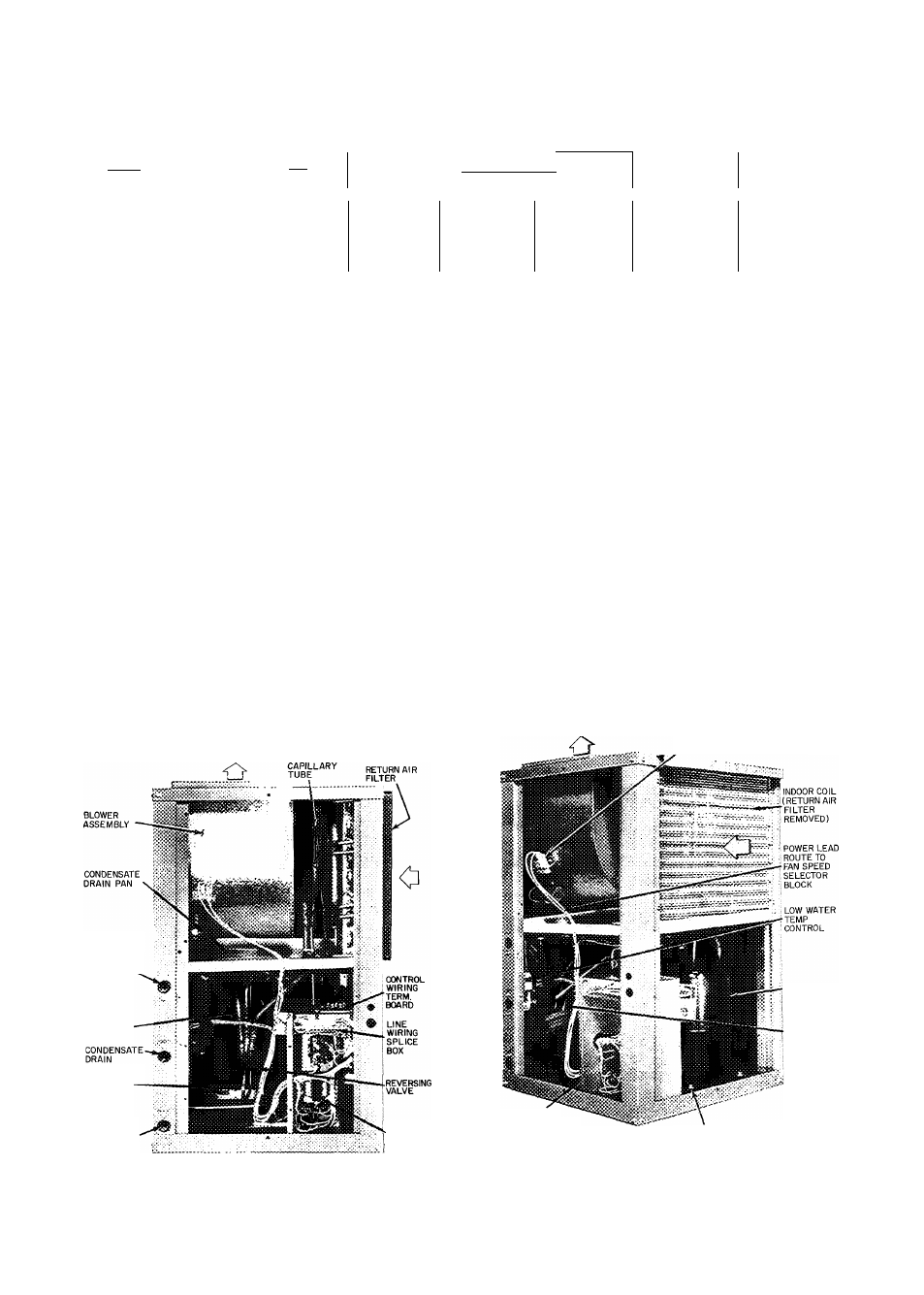

FAN SPEED SELECTION BLOCK

(MOLE.X PLUG)

J FPT WATER

OUTLET CONN

SUCTION

SCHRADER

FITTING

DISCHARGE

SCHRADER

FITTING

J"FPT WATER

INLET CONN

24-V

TRANS

Fig. 5

CONTROL BOX

AIRFLOW

Component Location

6

COMPRESSOR

HEAT

EXCHANGER

COMPRESSOR HOLD-DOWN

BOLTS (4)

i