Start-up, Unit controls and safety devices – Carrier 50WQ User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

M

_____

—^YEL —

_____

—^YEL —

1-PHASE

CONN TO

DISCONNECT-

PER NEC

GROUND

LEAD

—^BLK —

,__^GROUND

—Hä] LUG

3-PHASE

CONN. TO

DISCONNECT-

PER NEC

---- - _

^^YEL-

^^YEL-

GROUND

LEAD

,__^GROUND

—C

ö

J

lug

50WQ

HEAT PUMP

CONTROL BOX

50WQ

HEAT PUMP

CONTROL BOX

I-PHASE

3-PHASE

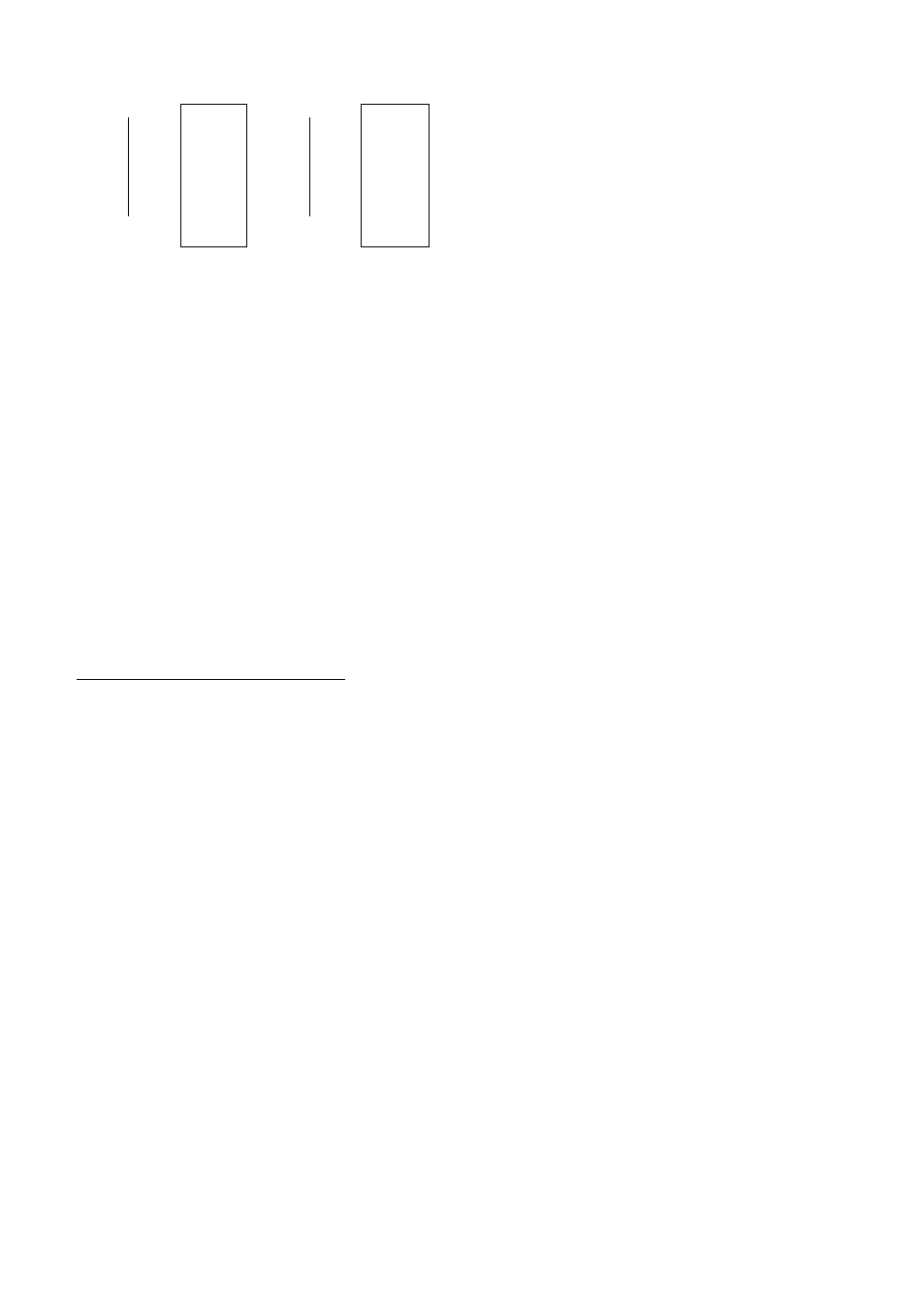

Fig. 3 — Line Power Connections

SET FAN MOTOR SPEED — All units are factory

wired for high fan speed operation. Set fan motor

for medium or low speed operation as follows:

1. Remove unit fan section access panel.

2. Locate Molex fan speed selector block on fan

housing, Fig. 5. Selector block receptacle 1 is

high fan speed, receptacle 2 is medium fan speed

and receptacle 3 is low fan speed. Yellow and

black fan motor power leads from control box

are connected to selector block receptacle C and

1. Yellow lead is common, black lead is speed-

change lead.

3. Change fan motor speed by removing black lead

from selector block receptacle 1 and plugging it

into receptacle 2 or 3. Receptacle 4 is not used.

CAUTiONt For proper rniit operaiioit, set unit

fast inoitor ;^>eed ibr air tjuantity

m tìàa

range

&ÌK>wn in Tabie

4,

Set fan motor speed on 460-volt units — Two-speed

fan motor is factory wired for high-speed operation.

(Yellow and black power leads from control box are

connected to the yellow and black fan motor leads.)

Change fan motor to low speed by wiring as follows:

1. Splice the violet and black fan motor leads

together.

2. Splice yellow and black power leads from control

box to yellow and red motor leads. (Yellow-to-

yellow and black-to-red.)

CONNECT CONTROL POWER WIRING (24-v)

— Power leads are brought thru 1 / 2-in. hole pro

vided in unit. Fig. 1. Extend leads to low-voltage

terminal board located on top of control box. Fig. 5.

Connect leads to terminal board as shown in Fig. 3.

Use room thermostat HH01AD042 and thermo

stat subbase HH93AZ044 for proper unit operation.

Be sure that field-installed jumper wire is connected

between subbase terminals W and Y. Set thermo

stat heat anticipator at 0.45 amp for 1-phase units

and 0.50 amp for 3-phase units.

START-UP

Water Flow and Temperature Data

1. Consider design water flow rates for efficient

operation. See Table 4 for permissible water flow

range.

2. Ensure that water temperature entering unit is

between 45 F minimum and 90 F maximum. For

water temperature below 60 F, insulate supply

line and install a secondary drain pan under the

unit to remove condensate from heat exchanger

and internal plumbing.

CAUTION: Water teniperattJre otttside

specified temperature range may cause

damage to uiijt.

3. Ensure that supply water is clean and air is

purged from system. Air in supply water causes

scaling in heat exchanger. Foreign material in

water and/or excessive velocity of water can

cause damage to tubing.

4. When using a semi-closed system with an “open”

cooling tower, a water treatment system should

be operational with initial water flow.

To Start Unit

— Ensure that air filter is in place on

unit filter flanges provided. Do not operate unit

without filter in place. Adjust the thermostat as

follows:

1. Set selector switch at OFF.

2. Turn on main disconnect switch to unit.

3. Set fan switch as desired (ON or AUTO.).

4. Set thermostat dial at desired temperature.

5. Set selector switch at HEAT or COOL.

Check system refrigerant charge. See Refrigerant

Charging on page 6.

-^Unit

Single-Phase

Compressors

that

are

equipped with a compressor start thermistor (PTC

device) — When supply voltage is within limits

indicated on nameplate and compressor will not

start, check the thermistor with an ohmmeter.

If the PTC is good, and the compressor does not

start, disconnect the PTC from the starting circuit

and give unit a temporary capacitance boost. Refer

to Carrier Standard Service Techniques Manual,

Chapter 2, for details on capacitance boost pro

cedure. If unit does not start with capacitance boost,

compressor may be defective. If unit does not start,

check starting capability with PTC assistance. If

questionable, remove PTC, add start capacitor and

start relay per start kit installation instructions.

WARNINGc Caftaciiaace boosa or ijistaliatioa

of start capadtor and start shtutki be per^

fonued by irauted persoaaet improper pro-

cedrn» couici cause

tajtjry or equipoaeat

damage.

Unit Controls and Safety Devices

HIGH-PRESSURE RELIEF VALVE (except

50WQ0I4) is located in compressor. Relief valve

opens at a pressure differential of approximately

550 psi between suetion (low side) and discharge

(high side) to allow pressure equalization.