Electrical, A warning, A caution – Carrier 58SS/DH User Manual

Page 5: Start-up, adjustment, and safety check

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

MORE THAN

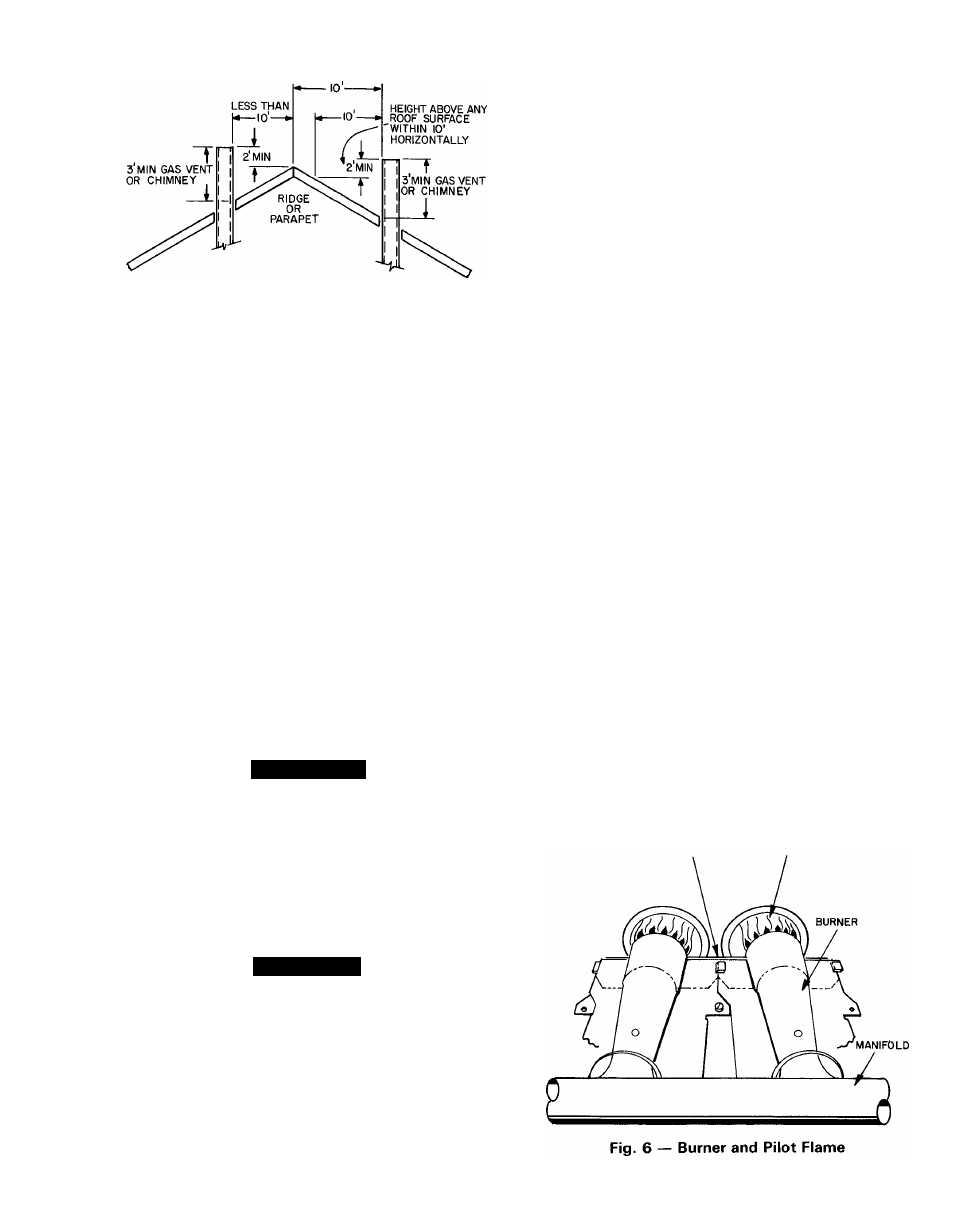

Fig. 5 — Chimney, Gas Vent Height

Type-BI Gas Vent

— Note that this furnace may

be connected to type-Bl gas vents. Type-Bl vents are

suitable, providing the vent system always operates at

zero or negative pressure. The vent system of this furnace

meets this standard.

For

Replacement

Installations,

Refer

to

Appendix, page 7.

ELECTRICAL

IMPORTANT: Before proceeding with electrical

connections, make certain that voltage, frequency

and phase correspond to that specified on the furnace

rating plate. Also, check to be sure the service pro

vided by the utility is sufficient to handle the addi

tional load imposed by this equipment. Refer to unit

rating plate for equipment electrical requirements.

The specific furnace installation instructions contain

wiring diagrams which show the proper field high- and

low-voltage wiring. Make all connections in accordance

with National Electrical Code and any local codes or

ordinances that apply.

A

WARNING

The cabinet must have an uninterrupted or unbroken

ground according to National Electrical Code,

ANSl/NFPA 70-1984 and local codes to minimize

personal injury if an electrical fault should occur.

Ground may be electrical wire or conduit, approved

for electrical ground when installed in accordance

with electrical codes. Do not use gas piping as

electrical ground.

A

CAUTION

If manual disconnect switch is to be mounted on

furnace, select a mounting location where drill or

fastener will not contact electrical or gas components.

NOTE: Use only copper wire between disconnect switch

and furnace.

Check all electrical connections (both factory and field)

for tightness. This should also be done after the unit has

reached operating temperatures, especially if aluminum

conductors are used.

START-UP, ADJUSTMENT, AND

SAFETY CHECK

Intermittent Ignition Systems

— Check to be sure

all connections have been properly made, then proceed

as follows:

Light furnace, using the procedure outlined on the

lighting instruction plate attached to the furnace.

However, when lighting the pilot for the first time,

perform the following additional steps:

1. If supply line was not purged before connecting fur

nace, it will be full of air. It is recommended that the

ground joint union be loosened, and supply line be

allowed to purge until odor of gas is detected. Never

purge gas lines into a combustion chamber. Imme

diately upon detection of gas odor, retighten the

union. Allow 5 minutes to elapse, then light pilot in

accordance with instructions on furnace.

2. After pilot lights, main burners should light in

25-75 seconds. If main burners do not light within that

time period, adjust pilot flame, allow pilot to cool

for 5 minutes, repeat time check.

3. Locate pilot adjusting screw on top of gas valve.

a. Remove cap screw; turn pilot adjusting screw

counterclockwise to decrease burner-on time delay,

clockwise to increase burner-on time delay.

b. Replace cap screw.

Gas Input

— Determine gas input as follows:

d.

NATURAL GAS

a. Turn off all other gas appliances and pilots.

b. Measure time (in seconds) for gas meter test dial to

complete one revolution.

c. Refer to Table 2 for cu ft of gas per hour.

Multiply cu ft per hour times heating value of gas

(Btu/cu ft). Obtain heating value of gas from local

utility.

Example:

Btuh heating input = Btu/cu ft x cu ft/hr

Heat value of gas = 1070 Btu/cu ft

Time for one revolution of 2 cu ft dial = 72 seconds

Gas rate = 100 cu ft/hr (from Table 2)

Btuh heating input = 1070 x 100 = 107,000 Btuh

Measured gas input should not exceed gas input

shown on unit rating plate.

e.

PILOT

flame

BURNER FLAME